Swiss firm Blackstone Resources has achieved a series of important milestones for its proprietary 3D printing technology to print lithium-ion solid-state batteries. The company has been investing in the next generation of battery technology through its German subsidiary Blackstone Technology GmbH. This includes patented 3D printing techniques and research into the mass production of batteries, which has been shown to offer greater energy density and a higher number of charging cycles.

Blackstone Technology’s 3D printing process offers substantial advantages over conventional battery cell designs that use liquid electrolytes. These include significantly lower costs, a higher level of production flexibility when it comes to the format of the cell and a 20% increase in energy density. Moreover, by using this technology, the number of materials that do not store energy (i.e. copper and aluminum) could be reduced by up to 10%. These advantages can be achieved independently of the electrode chemistry.

Holger Gritzka, CEO of Blackstone Technology GmbH, commented: “Together with the developments we have made in 3D printing battery technology to date, this development paves the way for the mass production of solid-state battery cells. In addition to major markets such as the automotive industry, marine applications and new 5G wireless networks would benefit from the advantages that 3D printed solid-state cells can offer”.

Elon Musk has acknowledged the importance of both having access to the next generation of battery technology and the raw materials needed to produce these batteries. The demand for electric cars is likely to quickly outstrip the number of battery materials that these vehicles require, even with new technologies that aim to reduce the number of battery materials needed.

Musk expects that next generation of batteries will use significantly fewer battery metals, such as cobalt, but more nickel and lithium. In reality, demand for all these metals is likely to pick up significantly as Tesla is joined by large auto manufacturers that are also starting to roll out their first electric vehicles with plans to electrify their entire range of cars.

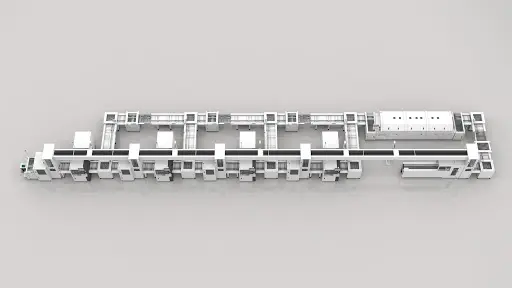

Blackstone Resources developed and tested 3D printed batteries that offer a significant improvement in terms of battery density, recharge cycles and costs. The Swiss company also developed a workflow to mass-produce these batteries in 2021 in any shape or form using proprietary battery printing technology.

Manufacturing on Demand

Having developed and tested this technology, Blackstone is ready to take the next step. To achieve the highest efficiency and greatest leverage from this 3D printing technology, the company plans to produce 3D printed solid-state battery cells.

This could be a game-changer for the development of solid-state batteries. An automated 3D printing production process could save up to 70% of the traditional Capex used to produce solid-state batteries. Solid-state batteries are also safer as they do not use flammable liquid electrolytes that are also more harmful to the environment.

The first solid-state battery prototypes developed by Blackstone Technology GmbH have already been tested. The company is now developing the 3D printing technology required to print these solid-state battery cells for mass production.

The production of these prototypes will demonstrate that Blackstone Technology can print many of the battery composites, casings and solid-state electrolytes needed for mass production.

Along with Blackstone, there is now a huge range of different competing companies vying to bring to market the next generation of battery technology. These companies are likely to beat Tesla when it comes to providing the next generation of technologies, which includes solid-state batteries and new advanced manufacturing techniques. This should be an issue for Tesla, which has significant access to capital and could quickly get up to speed through targeted acquisitions.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment