BCN3D Technologies’ Epsilon Series of 3D printers have been utilized by companies from the automotive giant, Nissan, to French multinational, Saint Gobain, to SJD Barcelona Children’s Hospital – where the technology has been implemented in over 200 surgeries per year.

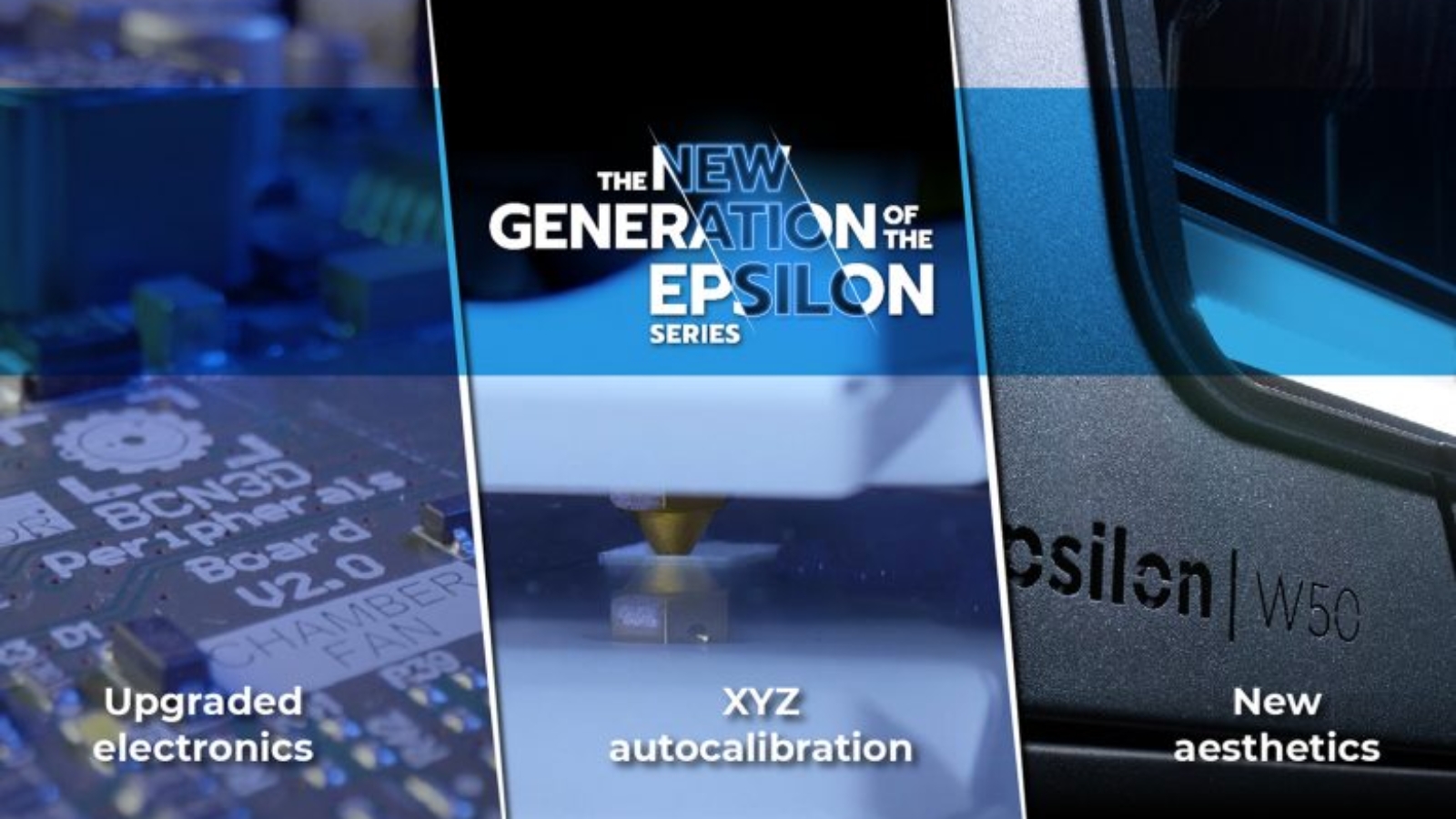

Now, BCN3D has upgraded its Epsilon Series (W50, W27, W50 SC, and W27 SC) – staying true to its commitment to keep its printing solutions state-of-the-art. Through the implementation of technical improvements in the hardware – the upgraded series is what the company believes to be its best printing solution to date.

BCN3D attributes a large part of the upgrade’s elevated efficiency to new and improved electronics, which include a new ventilation system, new motor drivers, a new main board, and local network access – an internal web server that allows users to access it via its local IP address, send files, monitor, and pause or cancel prints jobs remotely. This feature can also be used by owners of previous Epsilon versions, after a firmware update.

Manufacturing on Demand

Another recently added feature is the XYZ auto calibration, which is one of the fastest on the market – reducing user’s printing set-up time from 40 minutes to just six minutes, at the push of a button. This calibration process is done by measuring multiple points to automatically adjust the printing surface height and XY offset between both nozzles. This XY alignment ensures the nozzles are perfectly aligned – avoiding any crossovers or shifting layers when printing in dual mode using the Independent Dual Extrusion System (IDEX).

The printers’ frame has also been remodeled, and includes a more robust chassis that improves rigidity, and ensures the correct parallelism of the axes.

According to BCN3D, “Giving our Epsilon Series this makeover has been our way of taking on board customer feedback in order to ensure ultimate dependability. Rest assured, the new improvements have taken our 3D printing solutions in the direction of an even more powerful printing process.”

You might also like:

FITTLE and Velo3D partner on financing metal AM solutions: “Velo3D is experiencing impressive growth and increased demand, well on its way to becoming one of the largest metal additive manufacturing companies in the world,” said Nicole Torraco, President, FITTLE. “We look forward to supporting this growth as we provide new financing structures for their customers across various global markets.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment