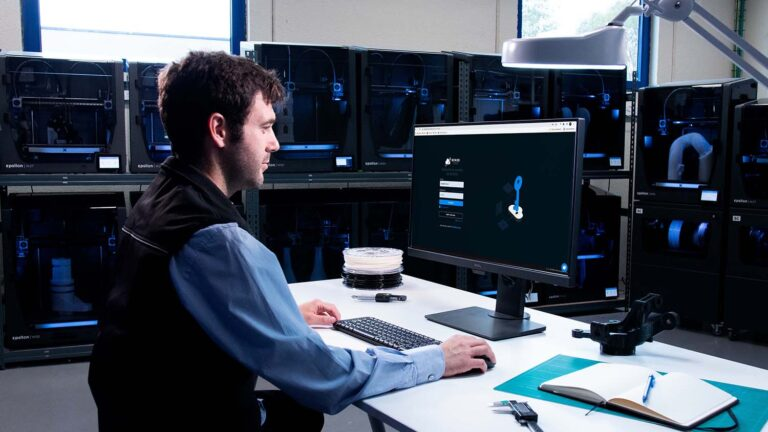

BCN3D released a complete reinvigoration of their current BCN3D Cloud platform. The new web-based cloud will allow companies to scale up their additive manufacturing operations and make entire printing workflows more efficient, controlled, and easier than ever before.

Apace with the continuously growing AM market, BCN3D’s main verticals in 2021 shifted to automotive, manufacturing, and engineering, with its main applications becoming functional parts, tooling, and low volume batches. The company’s transition from entry-level to workbench machines started in 2019 with the release of the BCN3D Epsilon and the materials partnership with BASF Forward AM and Mitsubishi Chemical. Later in 2020, BCN3D completed the Epsilon Series by launching the Smart Cabinet that ensures filaments are consistently kept at optimal humidity levels. In light of this deep hardware evolution combined with the growing demand for 3D printing, BCN3D set a goal of creating software to level up to their hardware solutions. The result is the new BCN3D Cloud, which centralizes all aspects of remote printer and resource management in one place for the easy implementation of a systematic workflow.

“For BCN3D’s current clients, the integration of AM processes in their business is becoming more critical as the applications are more demanding, an indicator of the tendency is that BCN3D machines are currently printing more than 12h a day on average. With such increasing printed part volumes, more people, and more machines interacting, the workflow needs to be robust and seamless. To support those customer needs, the vision of BCN3D is to provide software layers that add effective value on top of hardware, closing the circle of an enterprise-level solution.“ Daniel Arroyo, Chief Software Officer of BCN3D.

2021 has been key in the development of BCN3D’s software vision, with the release of the new slicer BCN3D Stratos and the addition of the integration with Teton Simulation’s SmartSlice for print parameter optimization. Alongside this, BCN3D has also worked with Autodesk to include BCN3D printers in Fusion 360, to offer users a fast-tracked printing process. Most recently, the new Cloud announced today has been built based on the Astroprint IP, a 3D printing software company known for its sophisticated cloud solutions, which was acquired by BCN3D this last July.

Manufacturing on Demand

Plans and availability

BCN3D has cultivated a brand new platform with a completely renewed user experience and interface to ensure frictionless usage. The new BCN3D Cloud will be available next 13th of October in order to make a smooth transition for current BCN3D customers. BCN3D has also announced three different plans.

The BCN3D Cloud Standard plan is included for all BCN3D customers (Epsilon Series and Sigma D25) and is ideal for driving the adoption of additive manufacturing within companies. Its main features are the digital library, queues management, organizing and prioritizing print jobs, and clusters. These allow users to group printers according to different characteristics or capabilities and view statistics, which provides companies with a real-time analysis to take actions based on data.

The BCN3D Cloud Teams system allows advanced organizations to administrate a departmental structure with customized roles and permissions for members. This plan also includes the Workflows feature, which permits the creation of several workflows in order to manage and control the printing process, all the way from design to the final piece. Depending on the role, some users can add files to the workflow while others are responsible for managing the printing process. The Teams plan will be available from late October onwards for a 3 month probation period, and then 495€ per year (595$/year).

Finally, the BCN3D Cloud Private is an on-demand plan dedicated to corporations that must be absolutely certain that their specific privacy and security requirements are being met.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment