Desktop Metal has begun shipping a new, intermediate version of its P-50 Production System, the new P-1 printer, globally to its early customer base. Key clients who have already received the machine include Ford Motors, an early investor in Desktop Metal, and Cetim, the Centre Technique des Industries Mécaniques, in France, which is the first European institution to receive it. The P-50 remains on schedule to begin volume commercial shipments in 2021: achieving this milestone will be a key passage in DM’s strategy for growth, especially now that the company is publicly listed.

With the ongoing crisis of the civil aviation segment, a major adopter and innovator in AM (and a key segment for most AM companies), many AM hardware manufacturers are accelerating and increasing their focus on the automotive segment. Serial production of automotive parts is seen as the next area of growth for metal AM (polymer AM automotive production is already somewhat underway). This transition was already underway and like many others has been accelerated by the new market dynamics created by the COVID-19 pandemic.

Automakers are responding. Just last week, Ford’s rival GM detailed the very significant investments in the new AIC AM center. Canadian AM news portal Fabbaloo also reported that SLM Solutions has installed one of its first giant 12 laser NXG 600 systems at Czinger. SLM Solutions is also now using the giant PBF system to work with Porsche on the development (and eventually production) of large EV powertrain components. 3dpbm will be publishing a new eBook on Automotive AM next January 2021 to analyze, map and report on all these latest developments, featuring new and exclusive content.

“Ford has been active in 3D printing since 1988 with the acquisition of the third commercially available stereolithography (SLA) system; we are very excited to be early adopters of the P-1,” said Cynthia Flanigan, Director, Vehicle Research and Technology, Ford Research and Advanced Engineering. “We expect that this new system will serve as an important tool in the development of our future advanced process and alloy implementation, enabling our researchers to investigate additional production opportunities of metal binder jetting at Ford Motor Company. Our early collaboration with Desktop Metal highlighted the need for a lab-scale system that is aligned with the functionality of the production scale system so we can further develop expertise around this process.”

Finding the market

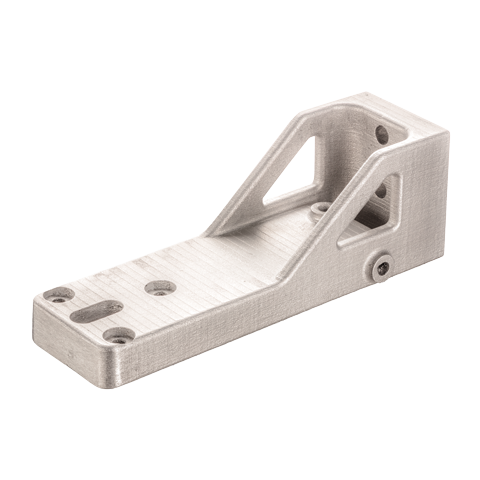

Designed to serve as a bridge from process development to full-scale mass production of end-use metal parts, the P-1 leverages the same patent-pending Single Pass Jetting (SPJ) technology and core additive manufacturing benefits for companies and research institutions alike at the size and scale of serial production. The P-1 is now available for order and has already begun to ship to initial customers, including to the Ford Motor Company, which will receive its printer this month.

“We know industrial businesses around the world are eager to begin working with the Production System P-50 and benefit from the fastest, most cost-effective way to manufacture metal parts of all levels of complexity at-scale,” said Ric Fulop, CEO and co-founder of Desktop Metal. “Adding the P-1 to our Production System portfolio serves as a key enabler for these companies as they look to develop processes and materials on a smaller scale before ramping up to mass production volumes. Similarly, many businesses and research institutions are also interested in leveraging the economics and quality of SPJ technology for mid-volume serial production, making the P-1 an ideal fit and a great stepping-stone to broad adoption of Desktop Metal’s technology and flagship P-50 printer.”

From P-1 to P-50

Created by leading inventors of binder jetting and single-pass inkjet technology, the Production System P-50 is an industrial manufacturing solution designed to achieve speeds up to 100 times those of legacy PBF additive manufacturing, enabling production quantities of up to millions of parts per year at costs competitive with conventional mass production techniques.

Manufacturing on Demand

The P-1 offers a new form factor to bridge the gap between benchtop process development and mass production, leveraging the same patent-pending SPJ technology and print carriage design as on the P-50 but with enhanced process flexibility. Also similar to the P-50, the P-1 features a state-of-the-art print bar with native 1200 dpi, advanced printhead technology that supports a wide variety of binders, and an inert processing environment to support both non-reactive and reactive materials, a key benefit for businesses and research institutions looking to experiment with a variety of materials. As a result, materials research and new application development conducted on the P-1 can be transferred directly onto the P-50 to scale to mass production, without the need to take this more industrial manufacturing solution offline for R&D activities, enabling efficient process development and new product introductions.

“For many businesses like Ford, the P-1 will serve as a learning lab for processes as they look to scale up to full production,” said Fulop. “Research institutions are also eager to adopt the Production System P-1 to experiment, validate materials, and test a variety of use cases for metal binder jetting with a smaller build box that offers all of the benefits of SPJ technology, including speed, quality, and reliability.

Cost-effective, serial metal parts production

SPJ technology on the P-1 is designed to print each layer in less than three seconds, including powder deposition, powder compaction, anti-ballistics, binder deposition, and printhead cleaning. At this maximum build rate, the P-1 can achieve production throughputs 10 times higher than those of legacy PBF systems(1) and fast enough to complete a full build in less than one hour.

The P-1’s open material platform and inert process environment allow customers to use low-cost, third-party metal injection molding powders across a variety of materials, making the P-1 suitable for cost-effective serial production of small and complex parts in addition to smaller-scale process development activities. Powder reclaimed during the printing and depowdering process can be recycled for future use, driving further cost efficiencies and resulting in a more environmentally friendly manufacturing process. In addition, the tooling-free manufacturing process on the P-1 facilitates quick turnovers to new jobs along with the ability to print many complex geometries simultaneously with no print supports required.

P-1 customers will also gain access to Desktop Metal’s Fabricate manufacturing build preparation software, as well as to the Company’s newly-released Live Sinter application, which dynamically simulates the sintering process and automatically generates print-ready geometries that compensate for the shrinkage and distortion that take place during sintering, minimizing process trial and error while improving accuracy.

The flagship Production System printer, the P-50, remains on schedule to begin volume commercial shipments in 2021, paving the way for the mass production of end-use parts, and unlocking throughput, repeatability, and competitive part costs.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment