New Silicone 3D Printing Method by University of Florida Could Benefit Millions of Patients 3D Printing Processes

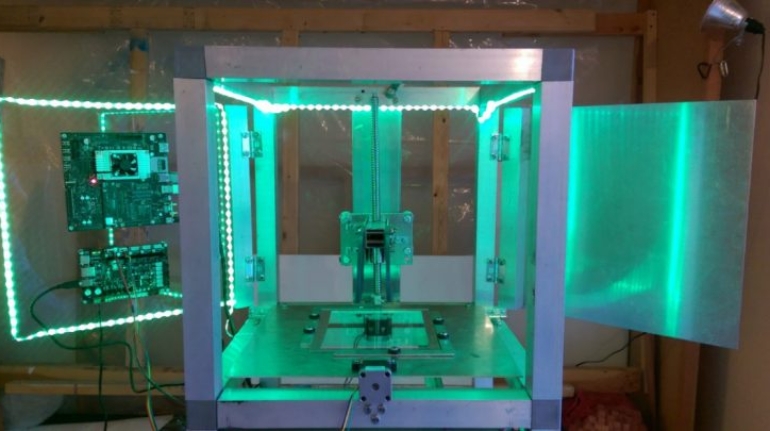

For the millions of people every year who have or need medical devices implanted, a new advancement in silicone 3D printing technology developed at the University of Florida promises significantly quicker implantation of devices that are stronger, less expensive, more flexible and more comfortable than anything currently available.