Solidscape S500 3D printer launches for faster prototyping and investment casting 3D Printer Hardware

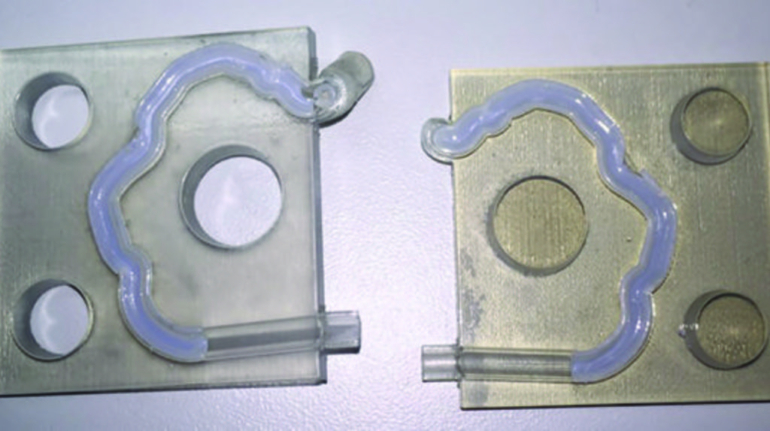

Solidscape, the Stratasys-owned leading producer of high precision 3D wax printers, is taking precision investment casting and rapid prototyping of complex geometries to the next level with the launch of the S500 high precision 3D printer. The Solidscape S500 and relative materials, which were introduced earlier this year at the Design Engineering & Manufacturing Solutions Expo in Tokyo, Japan, The new printer and materials are available for immediate purchase