Sintavia and TRUMPF Align on Machine Qualifications for Aerospace Applications AM Industry

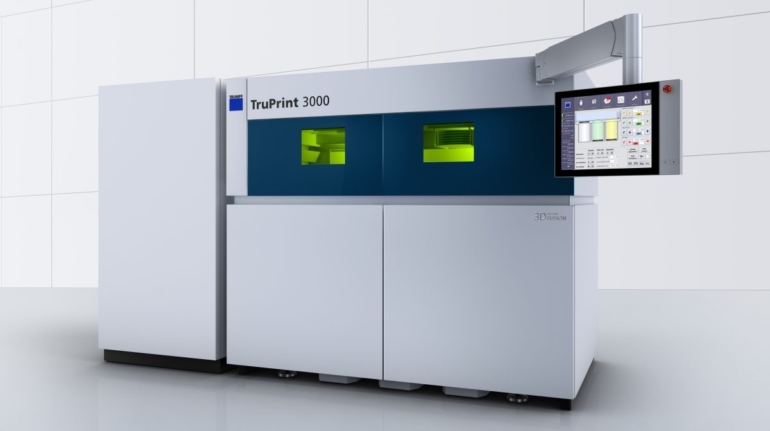

Sintavia, LLC, the global independent leader for metal Additive Manufacturing (“AM”) services, and the TRUMPF Group, a leading high-technology company offering production solutions in the machine tool and laser sectors, have come to an agreement to work together to accelerate the penetration of TRUMPF TruPrint metal printers within the global aerospace industry. The agreement, which involves a TRUMPF TruPrint 3000 with industrial part and powder management being installed in Sintavia’s Davie, FL, manufacturing facility, marks the start of a new strategic alignment for both companies.