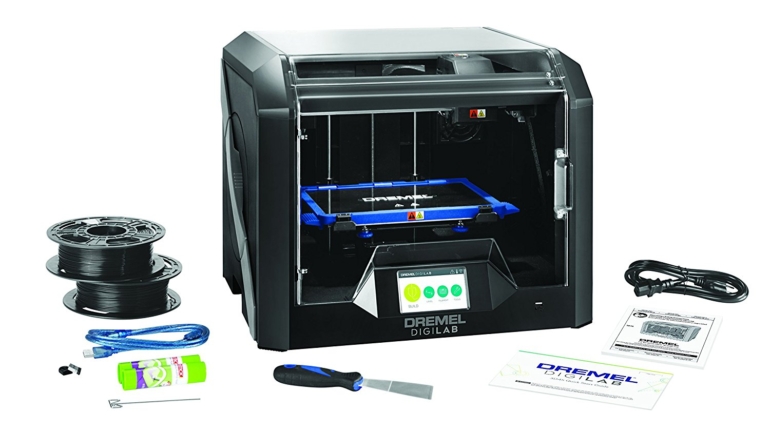

Powered by cloud-based 3DPrinterOS workflow software, the Dremel DigiLab 3D45 is being presented as “the most reliable and easiest-to-use 3D printer for advanced users in higher education and corporations.” Launching on Amazon next November 1st, the latest successor to the original Dremel Idea Builder, it has a heated build plate and robust extruder enabling the use of more advanced filament types such as nylon and 3DPrintLife‘s eco-ABS. To make things easier, the 3D45 has filament detection via RFID that enables the printer to automatically recognize and change settings for optimized printing.