LPW Technology and Global Advanced Metals co-operate on 3D printing of tantalum Materials

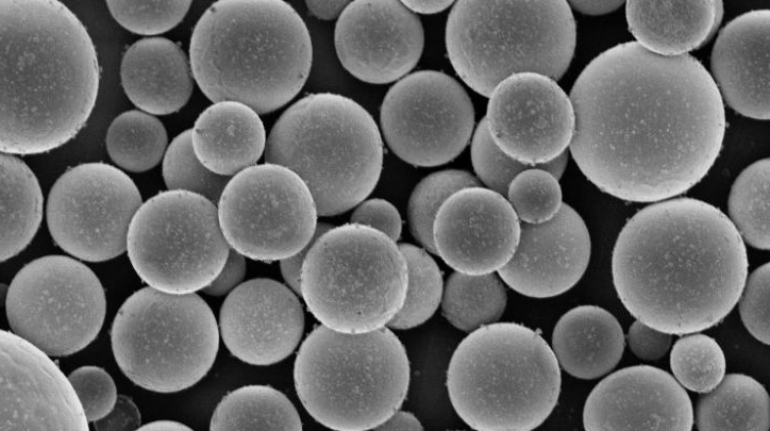

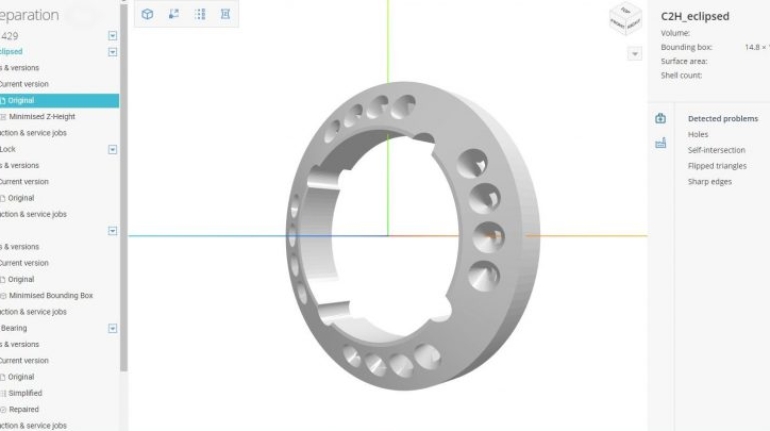

LPW Technology (LPW) and Global Advanced Metals Pty Ltd (GAM) are cooperating to further demonstrate the suitability of spheroidized tantalum metal powder for 3D metal printing. Across this emerging industry, there are few examples of additively manufactured refractory metals, and a need exists for a more thorough proof of concept and development of print criteria. GAM is filling this void and expanding its product portfolio.