Liquid Printed Pneumatics: BMW & MIT reimagine car interiors with adaptable 3D printed inflatables 3D Printing Processes

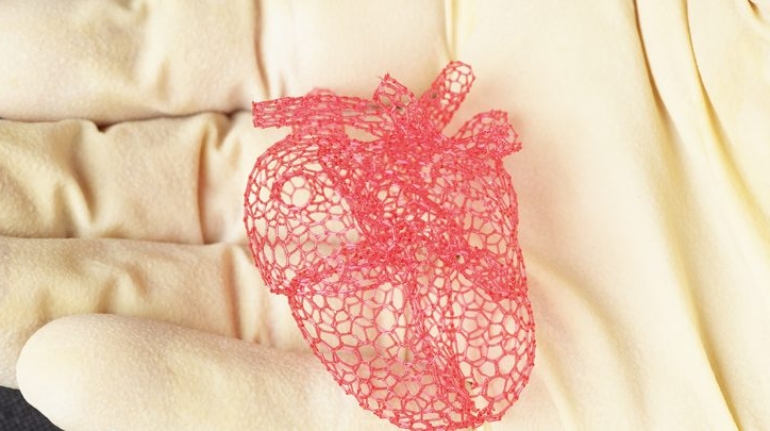

Arguably one of the most cutting-edge niches of the additive manufacturing sector is the development of dynamic and changing printed structures. Sometimes referred to as 4D printing, we’ve seen researchers 3D print self-folding structures and other smart, shapeshifting materials. A recent development coming out of MIT’s Self-Assembly Laboratory has demonstrated a new type of dynamic printing which integrates pneumatics for inflatable 3D printed objects.