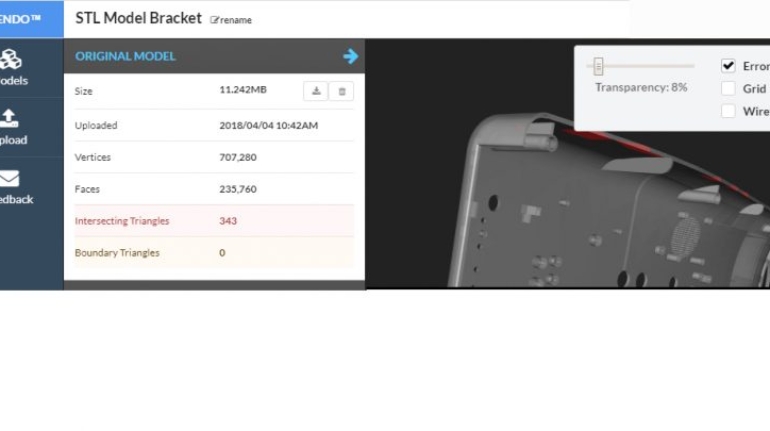

Avante Technologies introduces Emendo Cloud for streamlined STL file repair Marketing and Content

Avante Technology is introducing Emendo Cloud, a cloud-based automated STL File analysis & repair service. Targeted at engineers and professional designers, this high-performance repair service addresses three common problems with STL files, which are used for output to both subtractive and additive manufacturing systems: