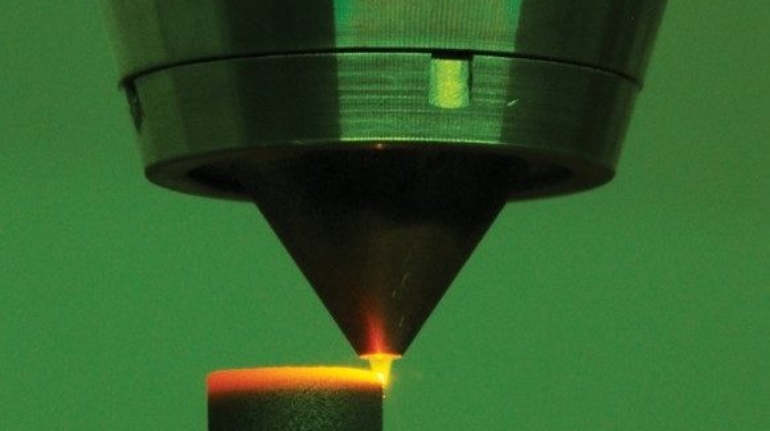

Alfa Romeo Sauber F1 Team adds five 3D Systems ProX 800 SLA 3D printers Additive Manufacturing

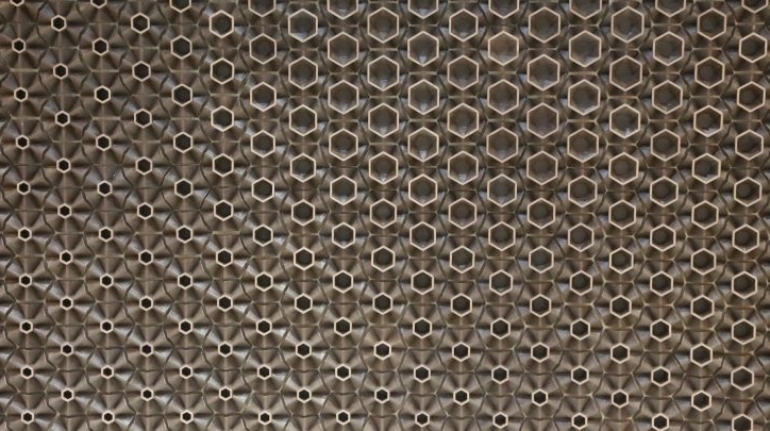

As Formula One becomes more open about the use of AM in its development and production processes, Alfa Romeo Sauber F1 Team has revealed that five new large-format ProX 800 SLA 3D printers from 3D Systems have joined its extensive arsenal of 3D Systems SLS and SLA solutions. In addition, the company is leveraging its experience and capabilities to provide additive manufacturing services and expertise to 3rd parties