Elli Srl’s ‘New Made in Italy’ Philosophy and the Integration of AM

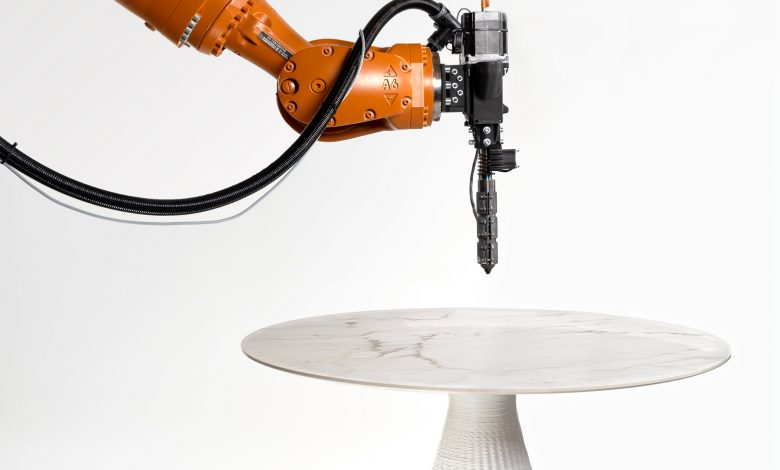

Elli srl is an Italian startup developing a new stylistic language in the field of furniture design, with a focus on product innovation and sustainability. Post Elli’s release of their ‘Soho’ and ‘Bryant’ pieces, and pre the release of their latest ‘Zero’ modular systems, we had the opportunity to speak with their founder, Alessio Elli, and find out more about how he has integrated AM into his world of furniture design and his ‘New Made in Italy’ philosophy.