3D printed fingerprint easily unlocks Samsung Galaxy S10 smartphone 3D Scanning Sevices

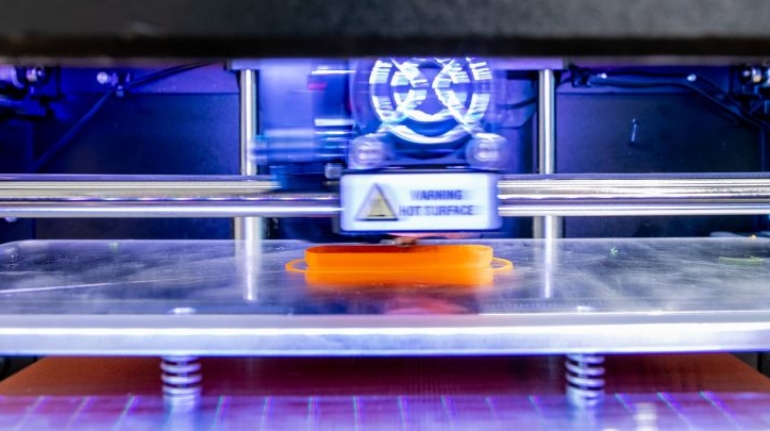

Whether a testament to the accuracy of 3D printing technologies or the vulnerability of the Samsung Galaxy S10’s unlocking system, a recent experiment by Imgur user [darkshark], which used a 3D printed fingerprint to unlock the smartphone, has gained significant media attention.