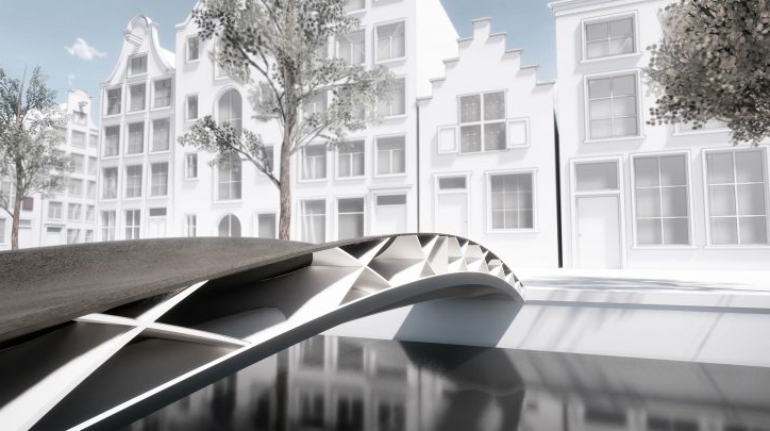

DSM, Royal HaskoningDHV and CEAD design 3D printed FRP pedestrian bridge Materials

Engineering firm Royal HaskoningDHV partnered with CEAD and DSM to design the first lightweight 3D printed FRP pedestrian bridge prototype using a composite material. It consists of a glass-filled thermoplastic PET (Arnite), combined with continuous glass fibers which are added in CEAD’s 3D printing process. This unique combination offers high strength with extreme versatility and sustainability.