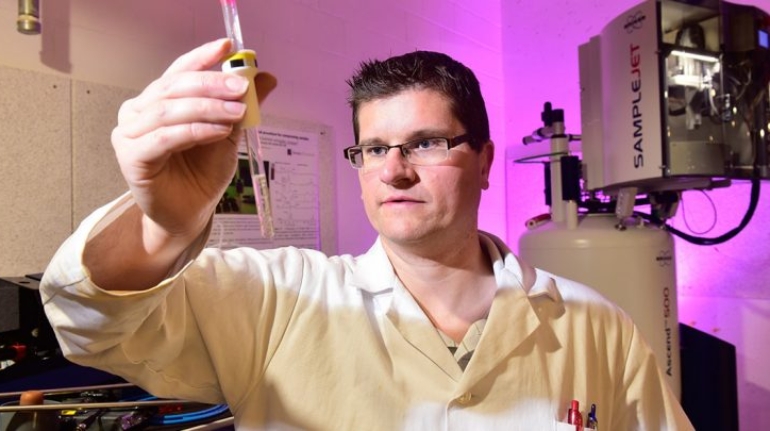

El Paso researchers sending bioprinted mini hearts to ISS Bioprinting

Biomedical researchers from Texas Tech University Health Sciences Center El Paso and the University of Texas at El Paso are working on a joint project to send miniature 3D bioprinted hearts to space. The research project, which has received backing from the National Science Foundation (NSF), seeks to understand how a microgravity environment affects the function of the human heart.