Philadelphia-based Authentise and Addiguru (Meteri, Louisiana) are combining their talents and experience through a collaboration to integrate in-process monitoring into additive manufacturing by expanding their Authentise Manufacturing Execution System (AMES) In the work process.

Combining artificial intelligence with workflow software enables real-time operations and is enhanced by the ability to create custom alarms, dashboards, and reports. The two companies hope their new products can provide a more simplified experience for users engaged in industrial use to make functional parts through the AM system.

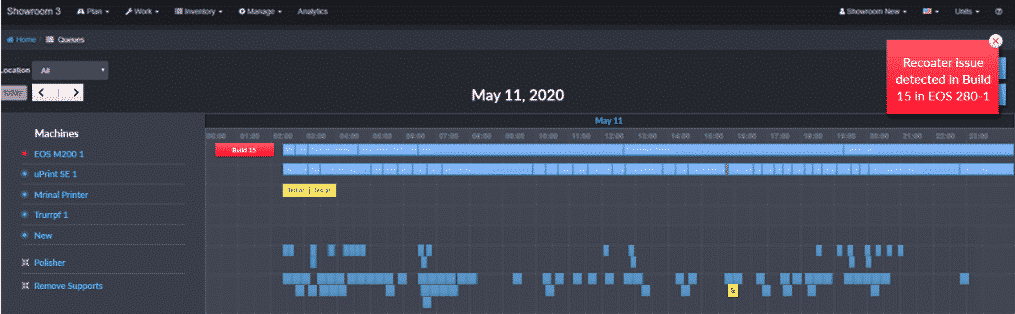

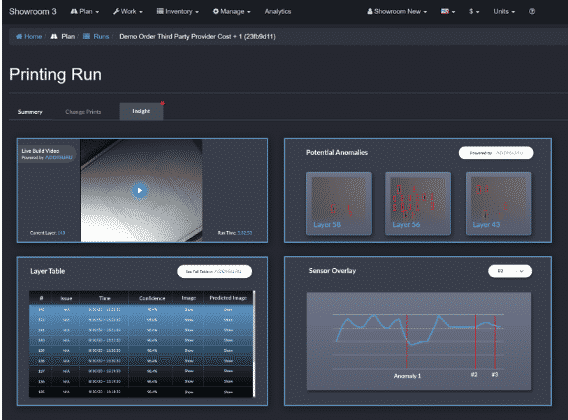

The Addiguru algorithm is responsible for providing notifications through the web interface and applications, reminding users of any possible problems by highlighting alarms in the workflow, and providing complete real-time traceability. Images and analysis of each machine and build are recorded:

“This includes the ability to overlay detected anomalies with sensor data taken from Authentise’s unique access to machine data,” states the Addiguru team in a recent press release.

“Existing in-process monitoring tools either require the user to have spent days setting up trial prints or to click through every image to detect potential flaws. The combination of our AI-driven insight and Authentise’s workflow tools enables the user to gain practical benefit in a system they love by having all data and notifications in one place.” says Shuchi Khurana, CEO of Addiguru “This initiative with Authentise also moves us closer to our goal of an open architecture framework.”

“Alert Details” can be found on the “AMES Build Details” page, including video of the image feed, detected anomalies, layer details table, and overlay of sensor data captured by Authentise

Authentise was established in 2012 and currently sells both AMES for workflow management and 3Diax for manufacturing software modules.

“The collaboration with Addiguru is a success because each party brings unique skills: Authentise provides coherent control of the digital thread and access to machine data, to which Addiguru can add visual inspection and intelligent analysis,” says Andre Wegner, CEO of Authentise. “Our collaboration with Addiguru is testament to both Authentise’s openness and the continued inventiveness of the startup community.

“While incumbent providers try to develop everything in-house, we work with the brightest minds to ensure that critical, cutting-edge solutions enter the market rapidly. Addiguru joins a variety of partner modules in areas such as geometric search, mesh healing, or quoting. Their integration into our MES makes ground-breaking solutions accessible, affordable and seamless. We are proud to guarantee our clients that they will always have access to best-in-class solutions.”

Authentise products are currently used in applications from companies such as Boeing, Ricoh, 3M, and Danfoss. Whether using 3D printing for prototyping or creating functional products, these companies can enjoy many of the classic advantages of 3D printing-from affordability to manufacturing speed, traceability and improved quality. Addiguru is committed to creating monitoring solutions for 3D printing systems to help companies avoid major errors and material waste during the construction process. Their system is easily integrated into existing AM equipment.