Building on many years of close collaboration, AMT and HP have formed a new strategic partnership, focused on delivering advanced post-processing capabilities to HP customers. The partnership centers on an Integrated Post Processing Solution, known as PostPro DMS (Digital Manufacturing System), which provides full support through the entire 3D printing production workflow.

The new solution enables a seamless connection between the physical and digital elements of the workflow – from design to production to post-processing. Using the solution, customers can more efficiently, and cost-effectively, integrate and automate post-processing steps such as cleaning, chemical vapor smoothing, coloring, part sorting, and inspecting, to parts produced with HP’s industrial Jet Fusion 3D polymer printing technology.

AMT is working with several automation and software partners to package the whole solution, which will be delivered to HP customers from early 2023 onwards. The collaboration will be bolstered by partnerships with key players in the post-processing hardware and software space. Customers such as Oechsler, and others, have already committed to using the joint solution for high-value end-part production.

“We are excited to take our partnership to the next level with AMT given their shared vision, shared customer, and proven portfolio of post-processing technology. At HP, we believe leveraging partnerships that bring unique expertise to the end-to-end Multi Jet Fusion workflow is key to accelerating the scale of additive manufacturing to production,” said Wayne Davey, Global Head of Sales and Go To Market for HP’s Personalization and 3D Printing business.

Manufacturing on Demand

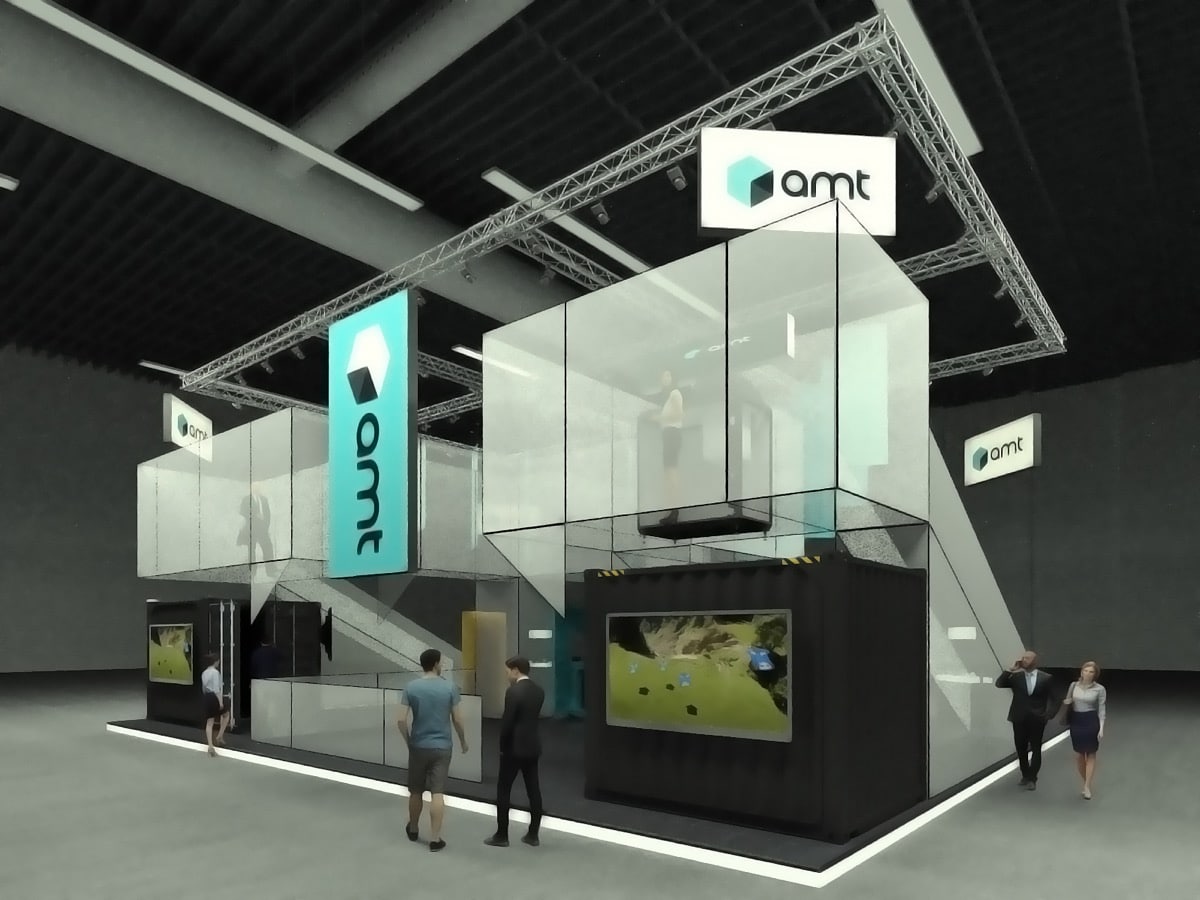

In addition to the full-scale Digital Manufacturing System, AMT has also designed a modular automated loader system to further optimize the post-processing workflow. The automated loader system loads batches of 3D printed parts to and from the PostPro SF100, enabling 24/7 chemical vapor smoothing. The automated loading system is well-suited for additive manufacturing users who may not have the mass production throughput for the DMS, but require more utilization out of their existing systems. AMT’s automated loader system is now available to purchase as an upgrade, with the PostPro SF100. Customers will also be able to view technology demonstrations at AMT’s faculties in the UK, Europe, and the USA, in 2023.

“AMT is committed to supporting HP’s customers to reduce their TCO while increasing throughput and repeatability and reproducibility of their 3D printing operations. We believe that this approach of providing a one-stop shop for an integrated post-processing solution is a first in the industry and will enhance HP’s value-add proposition in the market. We are incredibly excited to renew our partnership with HP, and to work together over the coming years,” said Joseph Crabtree, CEO, and Founder of AMT.

In addition to this, AMT and HP are working together on several technical development projects, including the coloring of automotive applications, specifically new white parts produced with the new HP Jet Fusion 5420W Solution, which will be on show at HP’s stand at Formnext.

At Formnext, both companies will showcase a variety of end-use applications, ranging from automotive to medical and consumer industries. Together, the companies will host an Expert Presentation on Wednesday, November 16th at 2:00 PM, to discuss how General Motors leveraged HP and AMT’s Integrated Post-Processing Solutions to enable the mass production of automotive components.

You might also like:

What’s happening in the innovative world of AM?: The additive manufacturing industry has been growing steadily in recent years. This can be seen in the 3D printing market and in the jobs market. There are 78% more active AM jobs in November 2022 compared to the same month in 2020, with hotbeds of 3D printing talent in the US being Los Angeles, San Francisco Bay Area, Greater Boston, Cincinnati, and Texas. In Europe, the major countries are Germany, France, Belgium, Italy, Netherlands, and the UK.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment