AML3D, an Australia-based enterprise of large-format metal additive manufacturing systems, is currently listed on the Australian Securities Exchange (ASX) and has raised AUD$9 million through an Initial Public Offering (IPO). AML3D is well known for its patented Wire Additive Manufacturing (WAM) technology, which has obtained certification from Lloyd’s Register.

It has been an exciting day for AML3D. The successful IPO of the company saw substantial investment in support from national and global retail and institutional investors, in addition to Perennial, an Australian investment management company. WAM, the provider’s metal technologies, is in the heart of what the provider provides. The approach is capable of forging methods and minimizing material waste by up to 80 percent in contrast to conventional casting.

“We would like to welcome all new AML3D shareholders and express our thanks for the exceptional support we received for the IPO,” said Andrew Sales, Managing Director of AML3D. “Transforming to a publicly listed company signifies a momentous event for AML3D, facilitating the acceleration of our commercialization pathway to meet the strong interest in our technology. We are confident the positive momentum will continue as we remain focused on delivering a customer value proposition through the rapid build of certified, large-scale 3D printed metal products.”

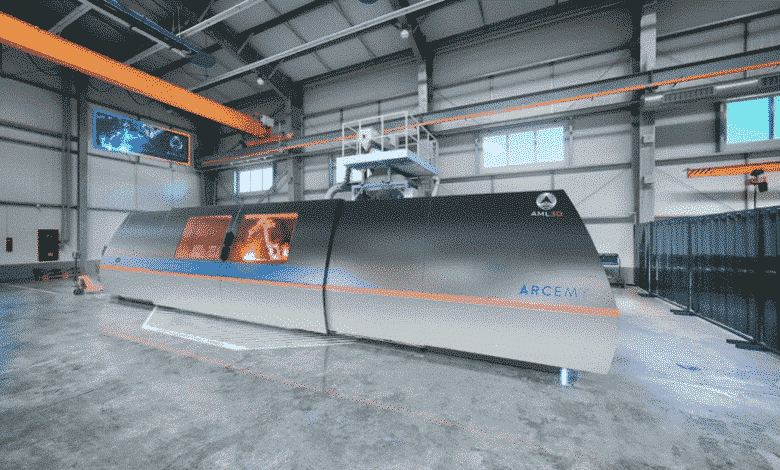

Besides ASX record news and its investment, AML3D has disclosed that it’s currently preparing the shipping of its initial 3D printer, known as to ST Engineering, a leader in defense and aerospace. The machine, to be set up has been set up as a member of a deal by which AML3D gets the right to utilize 50 percent of the capability of the machine in the area for contract production for clients. The Army system unites robotics technologies and welding program design to generate large-format, industrial-quality, and fully dense metal components.

“We are excited about the potential of supporting our customers who are global leaders in the industries of marine and defense,” added Sales. “These customers are a true testament to AML3D, highlighting the capacity of our innovative technologies and validating our experience and the team’s ability to implement deals with blue-chip global companies.”

The firm declared the shipping of a 3D printed Panama Chock. The component, a metallic element used to direct ships’ mooring principles, was sent as a member of a trial to permit the performance of the part to be evaluated by AML3D via a third party. The component was published out of carbon steel and can be allegedly 1.5 times more powerful than conventional cast versions. AML3D anticipates its 3D printing technologies will have applications in the sector. Keppel and aML3D are allegedly in discussions about future orders.