At this year’s Formnext in Frankfurt AM Solutions is presenting not one but three new machines. The new S1 Wet was specifically developed for the removal of residual powder and the surface homogenization and smoothing of metallic 3D components. With the S2 the experts for automated post-processing solutions are presenting the first shot blast machine for treating 3D printed components made from polymers in indexing, continuous flow mode. Of particular interest will be the C2 system that allows the chemical surface smoothing and application of a color dye in one single machine.

The increasing utilization of additive manufacturing for volume production of standard components goes hand-in-hand with increasing demands for quality, consistency, and cost-efficiency of the post-processing and surface refinement operations for 3D printed components. For this purpose AM Solutions, the division of Rösler Oberflächentechnik GmbH that specializes in automated post-processing and surface finishing solutions presents various innovative developments this year’s Formnext (hall 12, booth C 119). The new systems were specifically developed for the volume production of 3D printed components made from metal and plastic.

Manufacturing on Demand

One of these developments is the wet blast machine S1 Wet that was specifically developed for post-processing 3D printed components made from metal. Besides the removal of residual powder, the compact plug and play system also allows surface homogenization and smoothing. Depending on the surface roughness of the raw components, the S1 Wet can produce low Ra values. To a certain extent, this is even possible on the surface areas of internal passages and/or cavities. The wet process prevents small metal particles removed from the workpieces, dust, and shavings from creating a combustible or explosive mixture. Therefore, it does not require the installation of protective ATEX accessories. The water layer created on the part’s surface prevents abrasive media inclusions. As an option, an integrated wastewater recycling system consistently removes any contaminants from the slurry consisting of blast media and water limiting the water consumption. The S1 Wet system can be used for a variety of post-processing tasks ranging from the manual processing of single components to fully automatic batch operation.

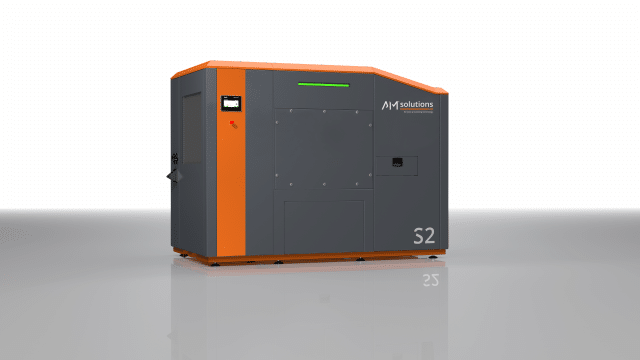

Placing entire batches of plastic components, produced with powder-bed printing systems, into a machine, selecting the respective processing program, and everything else running fully automatically. With its new ATEX compliant S2 shot blast machine, AM Solutions is fulfilling this demand for effective, time- and personnel-saving post-processing with repeatable results. After being placed in the S2 machine, the workpieces are gently passed through a special troughed belt in a single-piece flow. This allows the complete removal of any residual powder. Depending on the utilized blast media, the workpiece surface can also be homogenized or peened. The blast media cleaning and recycling system, integrated into the plug and play system, is a major reason for achieving absolutely clean and repeatable results. It ensures that the blast media remains at a consistently high quality. A patent application covering the machine and the process is pending.

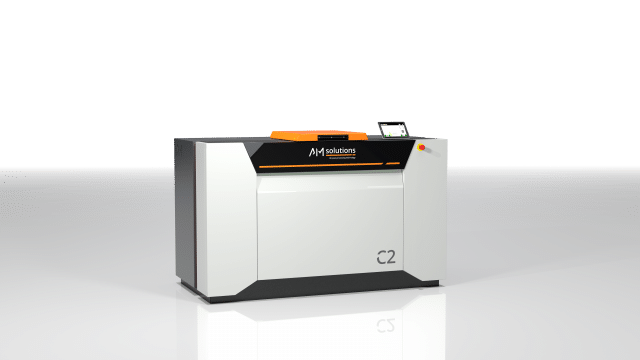

The design of the C2, presented at Formnext as a concept solution, is based on Rösler’s comprehensive know-how in the fields of equipment building and consumables. The innovative C2 system (pending patent application) allows the fully automatic chemical surface smoothing of 3D printed components made of common polymers and elastomers (including TPU) in series. Thus, the costly single-piece handling of the workpieces is completely eliminated for this post-processing operation. In addition, a future, the retrofittable update will also allow the application of a color dye on the workpieces. Of particular interest is that the non-hazardous processing media, developed by AM Solutions, permits the eco-friendly chemical surface smoothing so that the spent media can be easily disposed of without any environmental restrictions. The new C2 will be available commercially in the first quarter of 2022.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Andrea Gambini

Leave A Comment