American multinational consumer goods company Procter & Gamble (P&G) has signed a 3D bioprinting research and development agreement with San Francisco biotechnology company Aether.

Having initially made a commitment to the technology in 2015, through a $44 million 5 year research plan in collaboration with A*STAR Singapore, the organization is looking to advance the use of artificial intelligence (AI) in 3D bioprinting.

Speaking at the time of this initial grant Professor Elena Lurie-Luke, head of Global Life Sciences Open Innovation at P&G, said:

“We want to look at the possibilities of bioprinting. It’s definitely a very strong emerging area.”

“We have a number of different in vitro skin models we’re working on because we are very involved in beauty care. If companies are doing innovation and interested in new tools then bioprinting should very much be on their horizon.”

Artificial intelligence – the key to multimateriality

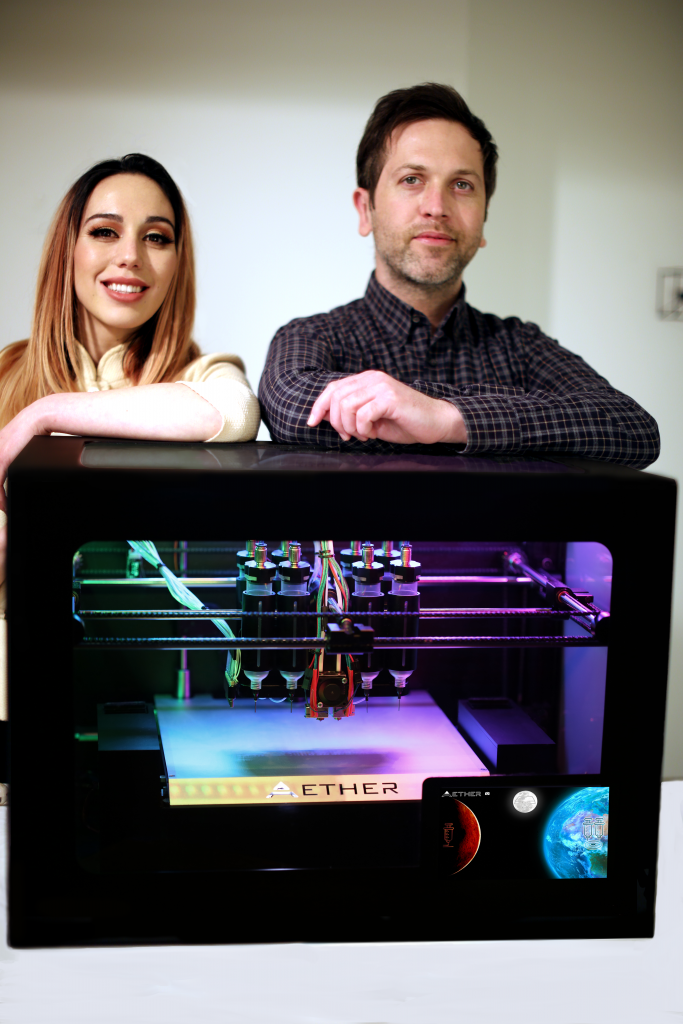

Aether is the developer of the Aether 1 multifunction 3D bioprinter. Fitted with a universal tool mount, the machine can be configured to use almost any tool, from CNC through to FFF printheads, though it is commonly used (and pictured) with its 8 pneumatic syringe extruders. Through the precise programming of these multiple syringes, the Aether 1 facilitates multimaterial 3D bioprinting – a necessity for the development of complex tissues.

Manufacturing on Demand

To support multimaterial bioprinting, Aether has been developing a design software powered by AI which, according to Aether CEO Ryan Franks, “is the only way bioprinting can reach its full potential.”

Redefining 3D printing

With P&G Aether is applying AI to the development of its next-generation 3D bioprinter. Detailing the project Franks says, “It’s no longer going to be just about depositing a material or two in a specific pattern.”

“We’re building something more like an intelligent robotic craftsman, able to perform highly complex tasks with many different tools, visually evaluate and correct its work throughout the fabrication process, and constantly learn how to improve.”

Using AI algorithms, fed by data from in-situ monitoring cameras inside the print enclosure, the project is akin to the current developments in metal additive manufacturing. In addition, Aether will also be developing automated image processing software for P&G, which applies machine learning to identify potential faults in a print.

Frank concludes, “Aether is working with P&G to completely redefine 3D printing.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Beau Jackson

Leave A Comment