Canada-based Adaptiiv Medical Technologies has confirmed the sale of $1.8M of its shares in an equity offering. The $3M offering, which now has around $1.2M left to be sold, made its first sale on June 21, 2019. Adaptiiv expects the offering to last no more than a year.

Overall, 20 private investors have contributed to the sales so far, with Alexander Capital set to rake in an estimated $225,000 in finder’s fees. The equity offering agreement states that Alexander Capital will receive 7.5% of the gross revenue from investors that the finder has introduced to Adaptiiv.

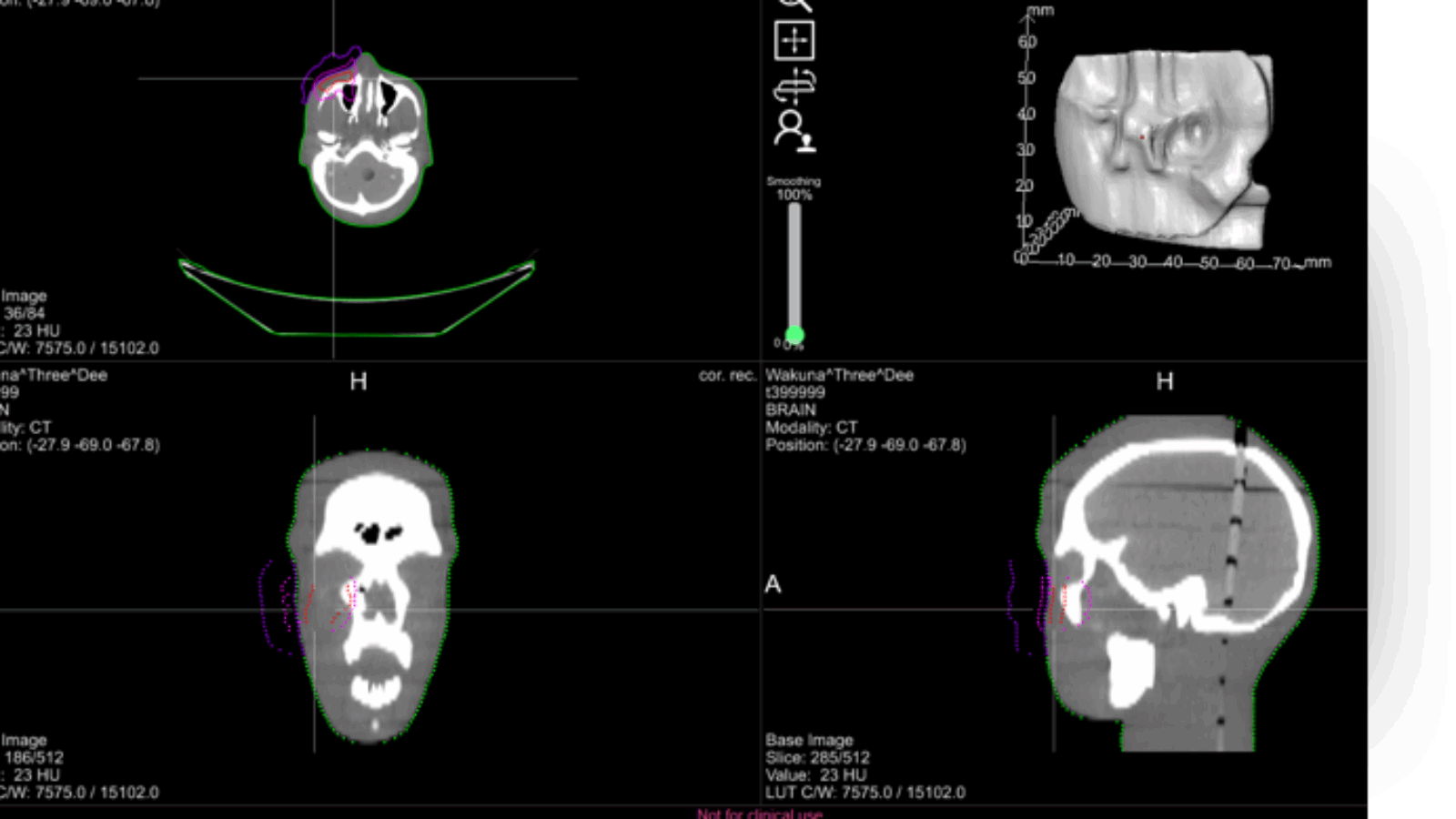

Adaptiiv boluses

While Adaptiiv has not revealed what the proceeds will be going towards, it is expected that the company will be further developing its proprietary cancer treatment software, which is the spine of its business model. The software converts patients’ CT scans into digital 3D models which are exported as STL files. The models are then 3D printed either by the hospital’s facilities or Adaptiiv’s own facilities if the hospital is lacking a 3D printer. The end result is a bolus that conforms to the patient’s specific individual anatomy.

In radiotherapy, boluses are required when cancerous cells are located around uneven areas of a patient’s body, such as the nose or ears. They control dosage by making up for missing tissue, or generating a build-up of dosage close to the surface of the skin. To be effective, the bolus must be made of a material that reacts like a real tissue when irradiated. The bolus must also be durable enough to hold its shape, not degrade over the course of treatment, and be cost-effective.

Manufacturing on Demand

Adaptiiv’s software is currently being used to create a number of different oncological devices, including the uniform thickness bolus, the modulated electron bolus (for modulated electron radiation therapy), and the high-dose-rate surface brachytherapy applicator.

The design freedom granted by AM makes the technology a strong contender for customizable medical devices and implants. Last year, 3D printed scaffold specialist BellaSeno commenced clinical trials for its 3D printed breast implants after previously achieving ISO 13485 certification for its breast scaffold technology. Not long before that, DePuy Synthes, an expert in orthopaedic devices, launched a new set of 3D printed titanium spine implants. The family of implants, named CONDUIT, have a Young’s modulus comparable to that of the porous tissue found in the center of human bones and come in various geometries and sizes.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Kubi Sertoglu

Leave A Comment