On November 19, 2019, the world’s largest 3D printing professional exhibition, FORMNEXT, was held in Frankfurt, Germany. More than 800 3D printing manufacturers from around the world participated in the exhibition, and more than 70 participants from China.

In this exhibition, eSUN focused on FDM 3D printing consumables, new best-selling photosensitive resin products, cost-effective 3D printing equipment, and innovative 3D printing solutions, bringing a new and high-quality experience to the audience.

eSUN exhibited the medical insole 3D printing system. This system was launched by Yisheng with many years of experience in materials and equipment. They aim at solving the most challenging problems of the orthopedic insole industry, and lead in efficiency, productivity, quality, cost, etc.,

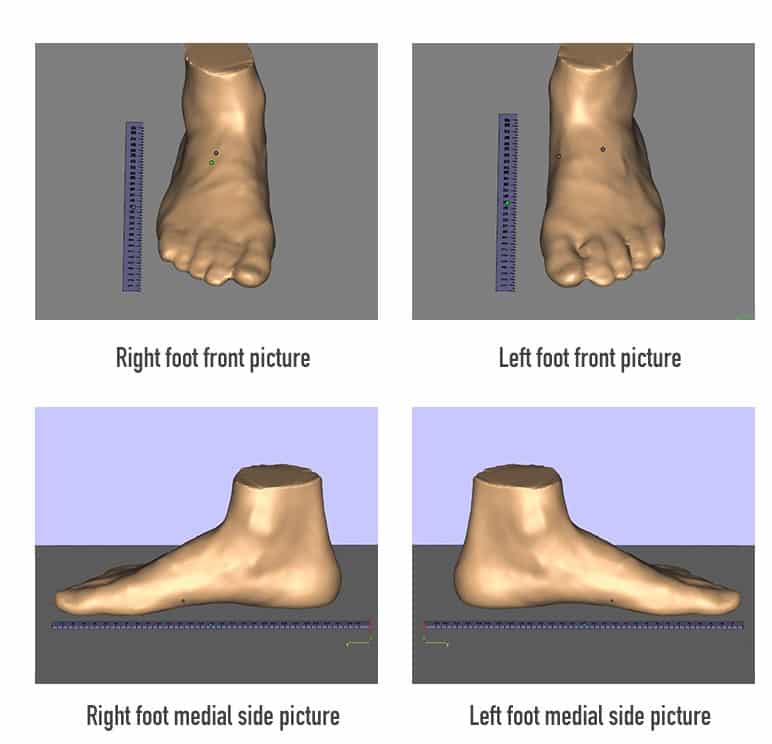

They firstly use 3D scanning to obtain user’s foot data, and then use ultra-soft TPU and iSUN3D FLX printer to produce a pair of insoles that are completely suitable for the user’s foot shape, thereby fixing and maintaining the foot health.

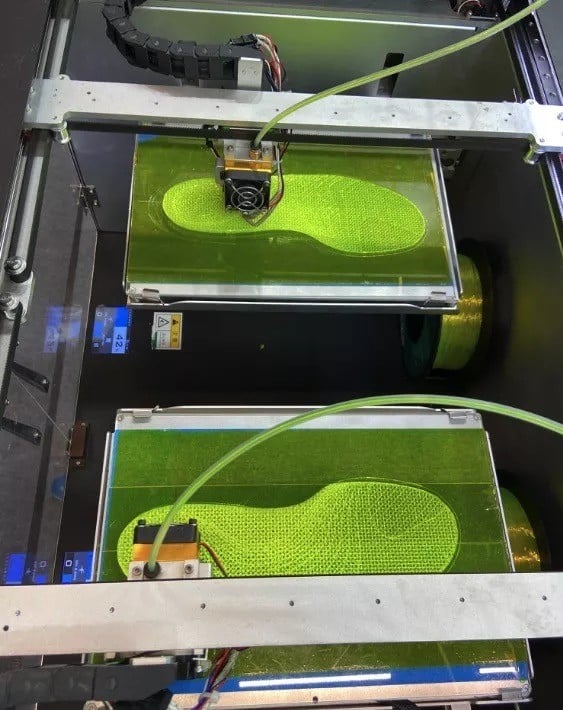

△ iSUN3D custom insole printing system: iSUN3D FLX high-speed flexible printer

The 3D printed insoles, made by the iSUN3D custom insole printing system, can help users reduce foot pain and other symptoms, and even change their foot shape. The iSUN3D FLX high-speed flexible printer displayed on the scene is the core 3D printer of this system.

△ iSUN3D FLX high-speed flexible printer is working

Features of The Printer

- Double plate, can print 2 insoles independently at the same time

- The production time of a pair of adult insoles is 40-60min

- Double E-axis motor, which extrudes the filament evenly and smoothly

- High-precision imported parts, ensure the prints with smooth surface

- 3.5 inch HD touch-screen monitor

- Can continue printing after recovering from power failure

△ Custom 3D printed insoles

The project is mainly applied to custom insoles in the direction of flat feet and sports insoles, superior to most of the medical insole systems. The iSUN3D custom insole printing system integrates all the relevant functions, from scanning to designing and printing.

First, using a 3D scanner to get the user’s foot data. Then modeling and printing with the ultra-soft TPU filaments. There comes a pair of 3D printed insoles that are completely suitable for the user’s foot.

- eTPU-95A filament is a consumable with high flexibility and high resilience, which can greatly reduce the permanent deformation rate of the material.

- At the same time, the characteristics like moisture permeability and hydrolysis resistance can make the samples undergo wet or dry, hot or cold working conditions.

- The flexibility and hardness of eTPU-95A are worthy of recognition. In these aspects, they are better than most of the similar materials.

- The size and shape of the prints are very stable.

- The prints are also easy to paint.

- The printing plate does not need to be heated and save energy in this way.

△ Foot Scanner

eSUN has developed this foot scanning – design and 3D modeling – 3D printing – post-processing system over several years. With its active innovation and active practical experience, it has now established insole design and 3D printing centers in Shenzhen and Xiaogan, Hubei.