Oak Ridge National Laboratory (ORNL) installed a new ElemX metal 3D printer from Xerox Elem Additive Solutions. The machine, which is going to be part of the Department of Energy’s Manufacturing Demonstration Facility (MDF) will enable the two entities to cooperate on the new Liquid Metal AM technology to continue advancing metal additive manufacturing.

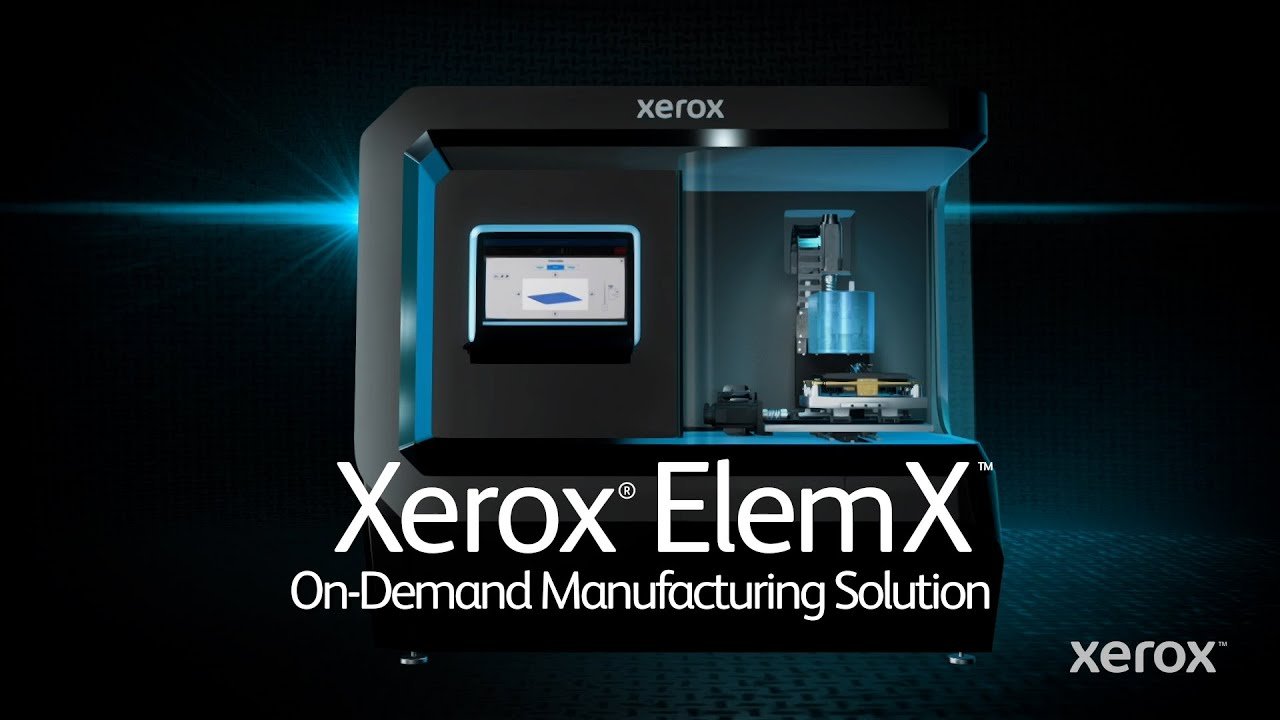

The ElemX leverages Liquid Metal AM that uses cost-effective aluminum wire and is easily deployed, requiring no special facility modifications for operation. Unlike many metal 3D printing technologies, the Xerox ElemX requires minimal post-processing and therefore provides a faster time-to-part.

“Developing metal AM technologies that are simpler to install and integrate into existing manufacturing operations will be key to increasing adoption throughout the industry,” said Xerox Elem Additive General Manager and Vice President Tali Rosman. “Oak Ridge National Laboratory has a long history of advancing innovative manufacturing technologies. This installation will enable us to further refine our liquid metal AM technology and achieve our goal of creating more resilient supply chains for our customers.”

Manufacturing on Demand

“ORNL has a long history of working with industry on alloy deployment and the improvement of material performance in AM,” said Ryan Dehoff, section head for secure and digital manufacturing at ORNL. “This process is promising for high-volume applications such as automotive; leveraging our experience with alloy development will help us expand the available number of alloys and applications.”

According to Dehoff, ORNL applies its science capabilities to solve challenges in AM by improving performance characteristics, optimizing systems and software to achieve mainstream manufacturing, developing qualification frameworks to create born-certified components and developing a comprehensive understanding of process capabilities and limitations through physics-based simulation and advanced characterization. Researchers at MDF work with hundreds of industrial partners to advance the state of the art in AM and open up new avenues for exploration.

The Xerox ElemX system is a safer and simpler metal 3D printing technology addressing supply chain resiliency for transportation, aerospace, defense and industrial manufacturing. Until now, the ability to 3D print aluminum consistently and reliably has challenged the market. Unlike other metal 3D printing technologies, there are no hazardous metal powders with ElemX and no need for PPE or other considerable safety measures. Engineered to bring simplicity to the supply chain process, ElemX is the ideal option for spares, repairs and low-volume production parts.

You might also like:

3DGence forges into Metal FFF 3D printing: “In the past 2 years, Metal FFF technology has made significant progress as an affordable entry into metal part prototyping and production. The number of desktop systems that can print open market metal filaments has increased, and the current key industrial players are experiencing consistent growth despite the economic impact stemming from Covid-19. 3DGence is now entering the Metal FFF segment with middle and compact-sized Metal FFF 3D Printers to provide a solid, reliable option in the entry and middle-priced segments – providing industrial-grade quality at scalable pricing with our ELEMENT Series MDM printers”, said Sebastian Sczasny – Technology Portfolio Director, MS Galleon / Group CEO, 3DGence.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment