Desktop Metal, a global leader in additive manufacturing technologies for mass production, has expanded its relationship with CNC software innovator, SolidCAM – creator of the iMachining toolpath technology and a leading distributor of solutions to precision metal manufacturers worldwide. SolidCAM has offered Desktop Metal’s printing products in Germany since 2021. Now, it will offer these Desktop Metal solutions to customers in the United States, where SolidCAM has technology centers, at its US headquarters in Newton, Pa., and Rancho Cucamonga, CA, as well as the United Kingdom, Israel, and India. SolidCAM has about 100 direct sales team members worldwide.

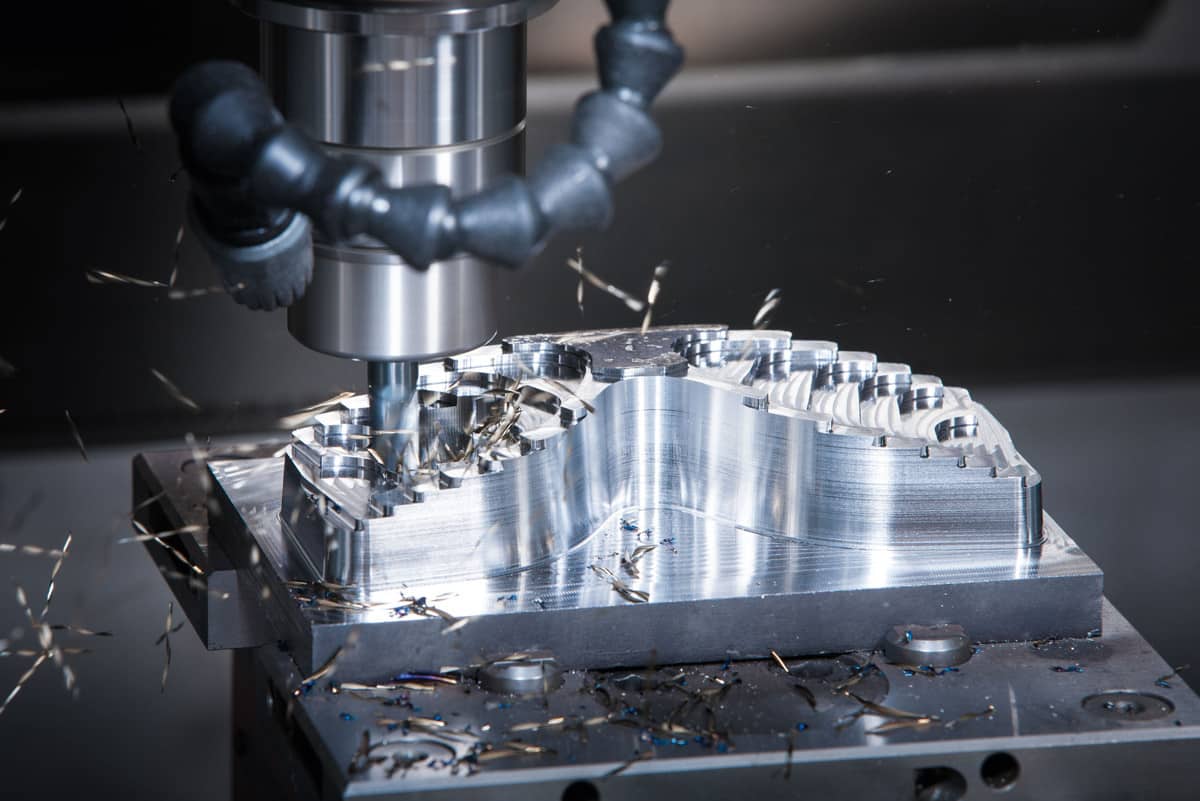

Additionally, new CNC + AM ‘Center of Excellence’ showrooms are currently being completed in Pennsylvania, Germany, and the UK, to demonstrate how Desktop Metal’s AM 2.0 printing solutions complement traditional subtractive machining technology and workflows. Additional facilities are also slated for completion in California, Israel, and India.

Manufacturing on Demand

“The Desktop Metal team is delighted to announce an expansion of our relationship with SolidCAM, a brand that is long trusted by machinists worldwide,” said Ric Fulop, Founder, and CEO of Desktop Metal. “This expanded partnership means that more CNC professionals will learn how easy it is to 3D print and sinter complex designs on our Studio System and Shop System metal AM offerings, freeing up capacity on CNC equipment, as well as machinist’s time. Additive manufacturing technology is truly complementary to machining, and we’re eager to deliver that message to the market in partnership with SolidCAM.”

“Our Schramberg Technology Center has already added a Desktop Metal Studio System to its current CNC machines, and we’re in the process of adding more Studio System and Shop System printers to our facilities worldwide so we can demonstrate how this additive manufacturing technology is complementary to CNC machining equipment,” said Dr. Emil Somekh, Founder, and CEO of SolidCAM. “The growing impact of additive manufacturing has been well documented. During the COVID-19 epidemic, 3D printing played a critical role in repairing vulnerabilities in supply chains, especially in the medical sector, and we think it can help improve the throughput of supply chains that remain challenged today.”

You might also like:

Divergent Technologies closes $80 million worth of financing: Under the terms of the venture loan agreement, Horizon, a leading specialty finance company that provides capital in the form of secured loans to venture capital-backed companies in the technology, life science, healthcare information and services, and sustainability industries, funded $15 million of the initial draw from the venture loan facility, and a private investment vehicle managed by Horizon Technology Finance Management LLC, Horizon’s adviser, funded the other $5 million. The venture loan facility provides up to an additional $40 million of funding to Divergent upon meeting certain milestones.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment