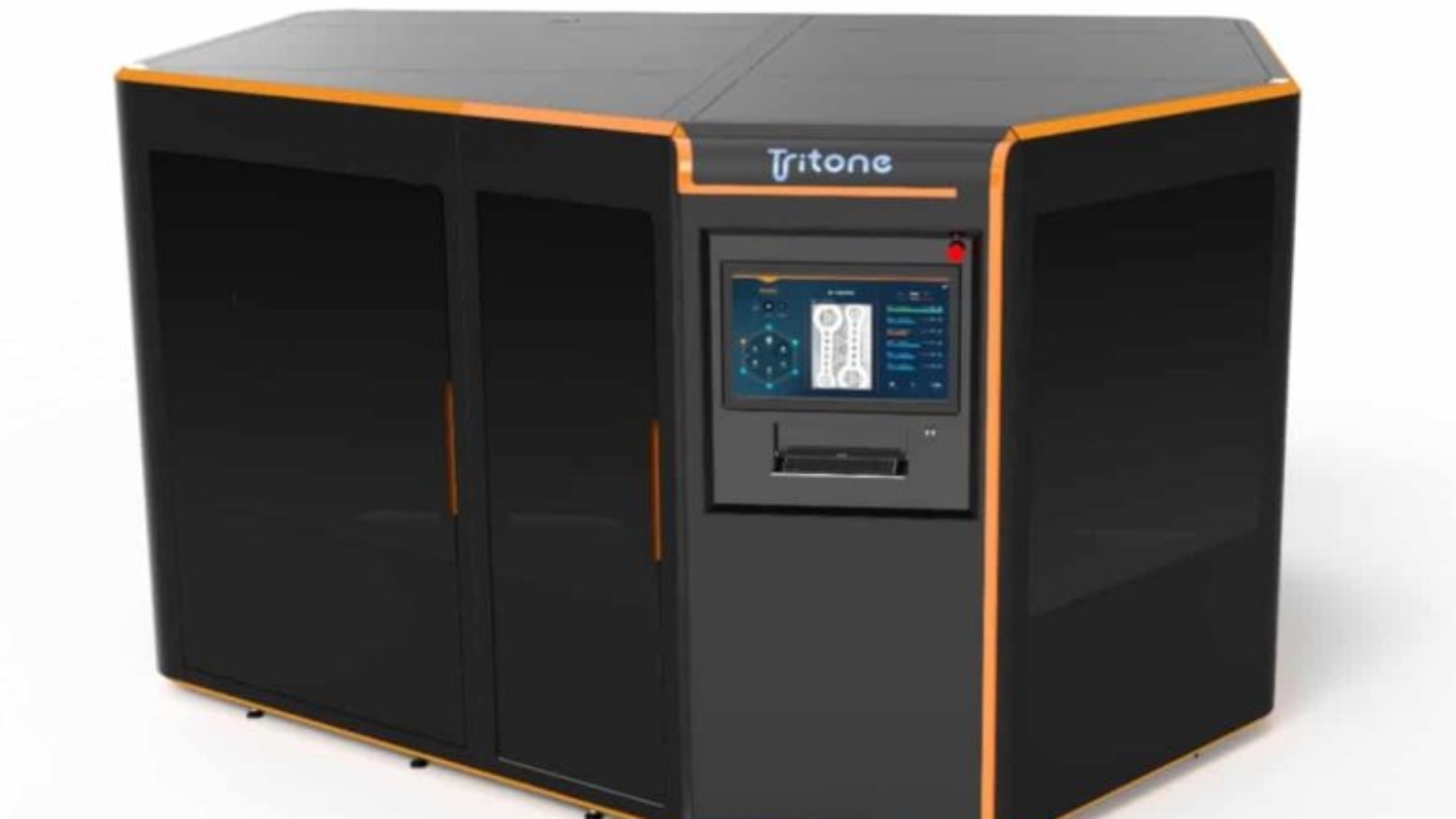

SU-PAD, a supplier of machines and equipment for the plastics industry, 3D printers, robotics, ultrasonic soldering, and lasers, has signed an exclusive distribution agreement with Tritone Technologies, a global provider of metal and ceramic additive manufacturing technology for industrial production – completing SU-PAD’s range of metal 3D printers and services offered in Israel.

“Experience, expertise, and high-quality service level in the AM field were important to Tritone when selecting a distribution partner in Israel. With SU-PAD, we have a competent and strong partner at our side in this region”, said Omer Sagi, VP of Products and Business Development at Tritone. SU-PAD has nearly 30 years of experience in selling and executing projects in additive manufacturing, injection molding, and robotics for industrial applications and has been a leading sales partner in Israel since then. In addition to expert know-how, SU-PAD contributes to the success of the new partnership with a proven distribution structure, its own training center, a service hotline, a demo center, and a professional additive manufacturing service.”

Manufacturing on Demand

In the last three years, Tritone has improved its Dominant system and has recently introduced the new Tritone DIM solution – increasing its set of available metal and ceramic materials to address the rigorous requirements of industrial applications. These enhancements include the advanced verification of layer quality, precision and uniformity, higher throughput, and improved streamlined post-processing of parts.

“We are excited about the new partnership with Tritone, that will enable our customers to manufacture their metal parts with true innovative technology. Due to this, they will have access to a vast library of materials with quality and throughput that only Tritone’s technology can achieve”, said Ziv Sadeh, CEO of SU-PAD.

You might also like:

Toyota Racing Development (TRD) names Stratasys as official partner:

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment