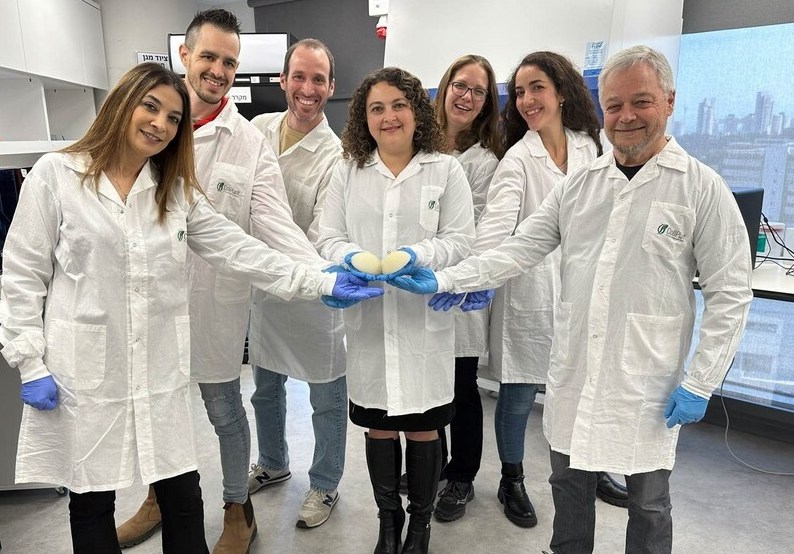

Regenerative medicine specialist CollPlant has announced that its proprietary 3D bioprinted breast implants have successfully passed animal testing.

Bioprinted from ‘rhCollagen,’ a plant-based alternative to human collagen, CollPlant’s implants are designed to promote cell regeneration, before gradually degrading into host tissues over time. Having reported “promising results” from its latest tests, the firm now plans to conduct further studies on implants that mimic “commercial-size products,” ahead of human trials and their launch to market.

“Our regenerative breast implants have the potential to address the safety challenges associated with silicone implants while providing a more natural looking and feeling aesthetic result,” explained Yehiel Tal, CTO of CollPlant. “We are very enthusiastic with the results of the study and the achievement of its primary objectives, including the clear demonstration of implant replacement by newly grown, native tissue.”

A plant-grown alternative to collagen?

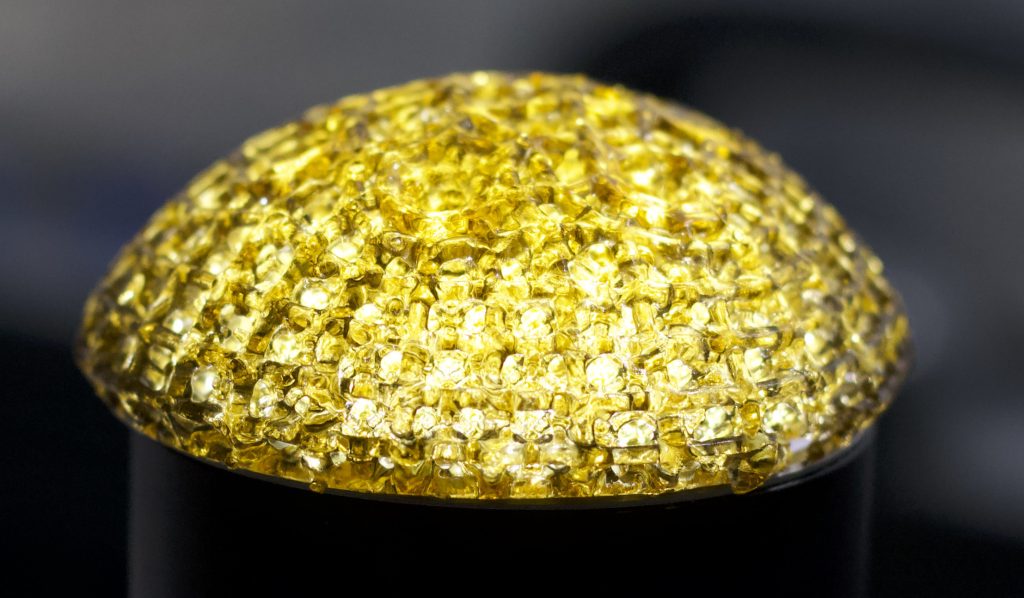

For those unfamiliar with the protein, collagen plays an essential role in the structure and function of human skin, cartilage, bones, and connective tissues. As a result, the market is full of collagen-based supplements, promoted as a means of boosting people’s skin, joint, bone, muscle, or heart health. However, with its technology, CollPlant is doing things differently, by growing a collagen alternative.

Essentially, the firm’s approach has seen it grow recombinant human collagen (rhCollagen) on genetically-engineered tobacco plants. Once ready, this is harvested and converted into a highly-purified 3D bioprinting material, which CollPlant views as a basis for developing the regenerative medicines and medical aesthetic treatments of the future.

Utilizing rhCollagen, the company has already created 3D bioprinted breast implants in-house. Designed via advanced modeling tools, these bioprints feature custom geometries that can be optimized to withstand varying physiological loads. The firm’s products are also able to facilitate breast regrowth before dissolving into host tissues, potentially making them safer alternatives to silicone implants.

Elsewhere, United Therapeutics has previously licensed CollPlant’s bio-ink for the serial 3D bioprinting of kidney scaffolds. In the past, CollPlant has also partnered with 3D Systems and CELLINK in separate initiatives, with the aim of developing products capable of addressing a lucrative regenerative breast implant market worth an estimated $2.5 billion.

CollPlant’s successful animal study

Manufacturing on Demand

Although CollPlant hasn’t published the full results of its latest study into the end-use viability of its 3D bioprinted implants, it’s safe to say it considers the trial a success. According to the company, “the objectives of the study were fully achieved,” in that the implants demonstrated “progressive stages of tissue regeneration” after three months in porcine hosts.

Not only are the implants said to have facilitated the formation of ‘maturing connective tissues and neovascular networks,’ but this cellular recovery was synchronized with its degradation, in keeping with desired trial parameters. Critically, there was no sign of adverse reaction in the surrounding tissues of any porcine test subject either.

As such, CollPlant says the outcomes of its trial support the ongoing development of rhCollagen-based breast implants as a “revolutionary and potentially safer and more natural alternative” to conventional silicone implants for aesthetic or reconstructive procedures, including postmastectomy for cancer patients.

Moving forwards, the company is planning a larger follow-up animal study later this year using commercial-size implants. The results of this are expected to inform future human studies as well as CollPlant’s commercialization plans.

Though the often-heralded potential of 3D bioprinting to create human organs remains decades from realization, the technology continues to make strides towards implantable tissues. Late last year, a patient who had lost some of her nose to cancer was treated with 3D bioprinted tissue fostered on her forearm, by clinicians at the Claudius Regaud Institute and Toulouse University Hospital.

At Prellis Biologics, meanwhile, the firm is utilizing the technology slightly differently, by developing a 3D bioprinted human lymph node for drug discovery and medical research applications. Believed to be the first of its kind, the immune system in a dish facilitates the study of B cell class-switching and somatic hypermutation, interactions said to be vital to the identification of new viral antibodies.

You might also like:

Scientists at the National Eye Institute have 3D bioprinted eye tissues from stem cells: Using their approach, in which three different types of immature choroidal cells are printed onto a biodegradable scaffold, the scientists say it could be possible to create an unlimited supply of patient-derived tissues. These, in turn, have the potential to help doctors better understand the mechanisms behind common degenerative retinal diseases, such as age-related macular degeneration (AMD).

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment