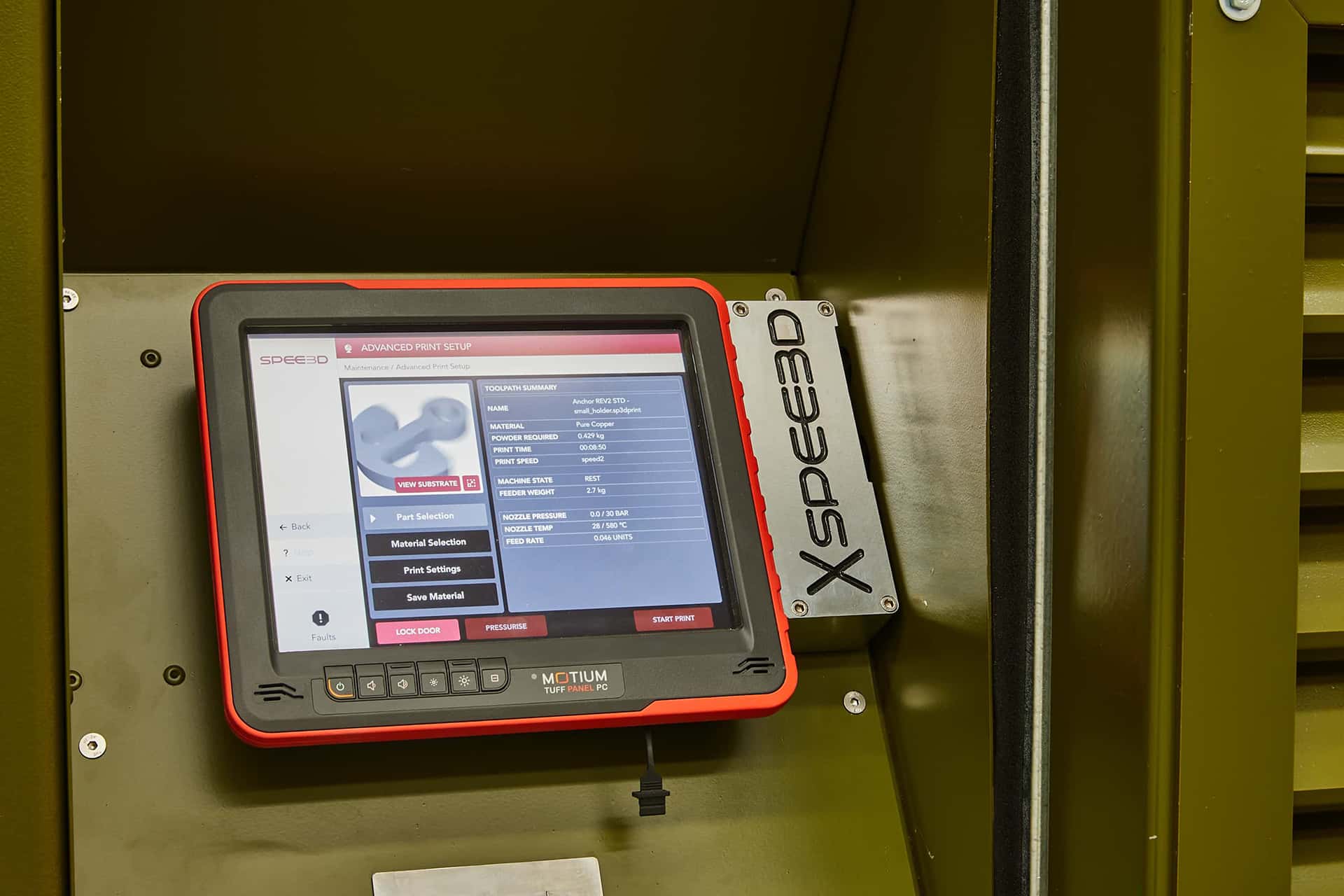

SPEE3D, the maker of some of the world’s fastest metal 3D printers, has unveiled its XSPEE3D printer – a containerized, ruggedized, and deployable cold-spray metal 3D printer that provides all of the necessary functions to print metal parts, from anywhere, in just minutes. XSPEE3D was designed based on extensive fieldwork and collaboration with the Australian Army.

XSPEE3D is fully transportable as a standard shipping container with the printer and all auxiliary equipment in one box. The printer is easy to use and deploy, requiring only a connection to electrical power. Once the printer is live, the fabrication of parts can begin immediately. According to SPEE3D, the XSPEE3D is 1,000x faster than other additive manufacturing options and can print one or multiple parts simultaneously.

“One of the most significant issues the military faces today is the ability to resolve critical spare part requirements in the field, a challenge that worsens in the face of global supply chain issues,” said Byron Kennedy, CEO of SPEE3D. “With the introduction of the XSPEE3D, we’re solving this issue with the ability to make reliable and affordable metal parts from anywhere, including in harsh, remote military field conditions. We understand the operational, economic, and supply chain issues Defense faces, and look forward to continuing to work with them to help solve these challenges.”

The UK’s Manufacturing Technology Centre (MTC), an independent research and technology organization that works with the military and other top companies, is partnering with SPEE3D to be the first organization to utilize the XSPEE3D printer.

Manufacturing on Demand

“Our goal at the MTC is to bridge the gap between industry and academia to showcase the world’s foremost technologies to our wide-ranging clients, including those in Defense, and metal 3D printing is crucial for us to understand and teach them,” said Dr. Ken Young, Director of Technology at the MTC. “We chose the XSPEE3D for its unique capability to be deployed in harsh environments, which makes it ideal for military use or for creation of spare parts in remote locations. This opens up a new area of application for additive manufacturing that until now has been unachievable.”

Unlike other printers, the containerized XSPEE3D can print quality 3D metal parts from over 12 metal alloys, including copper, stainless steel, titanium, high-strength aluminum, and nickel-based carbides, and can withstand extreme heat and rough terrain in the field. Uniquely, SPEE3D harnesses the power of kinetic energy rather than relying on high-power lasers and expensive gasses, allowing for affordable production costs.

Military partnerships are not foreign territory for SPEE3D. The company recently announced that its WarpSPEE3D printer was the first in the world to successfully print parts from a naval ship as part of the NCMS (National Center for Manufacturing Sciences) REPTX exercise. SPEE3D has been involved in field testing of their deployable technology with the Australian Army and Australian Navy since 2019.

You might also like:

Fortify delivers FLUX CORE 3D printer to IERUS Technologies: “Placing a printer at the IERUS Technologies headquarters provides a critical resource to support the growing need for additive manufacturing solutions in electromagnetics for defense,” said Eric Versluys, Director of Defense Programs at Fortify. “Fortify’s printers are uniquely positioned to print low-loss 3D printing materials, enabling performance advantages where traditional manufacturing falls short (due to machining, weight, and size).”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment