Californian pediatric healthcare specialist Rady Children’s Hospital has launched a new Digital Imaging and Communications in Medicine (DICOM) standardization software.

Created in-house by the hospital’s Helen and Will Webster Foundation 3D Innovations (3DI) Lab, ‘Media2DICOM’ converts 3D models of patients into the DICOM files often used by physicians to share data. In doing so, the program allows medical staff to more easily access anatomical 3D reconstructions, saving them time, while helping them tailor treatment to improve childrens’ clinical outcomes.

“With the right resources, we’ve been able to develop software suited to the hospital’s needs, making it easier for physicians to access personalized 3D models and other information for excellent patient care,” said Justin Ryan, PhD, Director and Research Scientist at the 3DI Lab. “This is the first time a software like this has been created in a vendor-neutral environment, so it’s really exciting to see what’s next on this path of innovation.”

The 3DI Lab’s accessibility initiative

Based in San Diego, Rady Children’s Hospital is a national leader in pediatric healthcare that serves as a care provider to more than 280,000 patients, or around 91% of the region’s children. The hospital is home to a 3DI Lab that specializes in creating 3D models and prints based on CT scan and MRI data, which support precise surgical and interventional planning, and help improve patient outcomes.

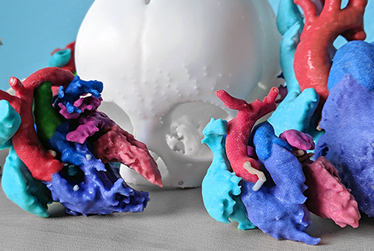

Under its innovation remit, the 3DI Lab works to facilitate in-house medical device fabrication, and develop resources to educate patients and their families on how procedures are carried out. The facility has also developed several models for surgical planning and the training of current and future physicians, including hearts with congenital defects via Stratasys’ J750 Digital Anatomy 3D printer.

More recently, the lab’s team has shifted focus onto targeting ways of making accessing the data behind such models easier. At present, Rady Children’s Hospital says many of the anatomical models created via industry-standard imaging systems aren’t accessible via ‘specialized 3D software.’ The 3DI Lab’s new program is designed to rectify this by converting patient data into standardized files.

An industry-first conversion software

The 3DI Lab’s Media2DICOM software is a tool designed to encapsulate files like MP4s, JPEGs, PNGs, BMPs and STLs in DICOMs. Practically, the program works by allowing clinicians to archive 3D models using a reference DICOM either stored locally, or sourced via the industry-standard Picture Archiving Communication System (PACS).

During the process, users are able to convert both videos of patients’ 3D models and 3D datasets themselves into standardized DICOM files. These files are then embedded within patient medical records and made accessible through the healthcare facility’s PACS, where other patient media, such as CT and MRI scans, are also available.

Manufacturing on Demand

Using this platform, physicians are able to view and interact with the anatomy of patients, allowing them to cater treatment to the needs of their unique physiologies. While the hospital’s website says that the program “is for research purposes only” and “is not intended for diagnostic use,” it adds that it could save doctors a huge amount of time in a way that “impacts the lives of thousands of children.”

The software is available now, and those interested can download Media2DICOM for free here. Moving forwards, Rady Children’s Hospital says that its 3DI Lab is also “working on advancing medical images using 3D printing,” as well as “developing in-house novel medical devices and several other in-house software projects.”

Anatomical modeling with 3D printing

Rady Children’s Hospital’s 3DI Lab is now one of several medical institutes to have turned to 3D printed models as a means of helping surgeons prepare for operations and patients better understand procedures. To facilitate this process, Stratasys has launched Digital Anatomy Creator, a software designed to manipulate material formations and customize internal structures in order to boost model accuracy.

Elsewhere, thanks to the high level of color fidelity attainable via its UV inkjet technology, Mimaki 3D printers continue to find clinical modeling applications. In June 2021, the University of Florence and Bompan revealed that they’d deployed one of its systems, alongside a unique algorithm, to develop accurately 3D printed full-color anatomical models.

Going further back to late-2019, GE Healthcare partnered with Formlabs as well, to make it easier for clinicians to 3D print patient-specific models from imaging data. Through their collaboration, the firms began offering a bundle that incorporated Formlabs 3D printers and materials, as well as GE Healthcare’s Advantage Workstation software, for the preparation of such models before production.

You might also like:

World-first 3D bioprinted bioimpedance chips unlock in-vivo skin disease modeling: By assessing a tissue’s sebum levels, the oily substance in human tissues that helps our skin barrier to function, the lab-on-a-chip devices are able to non-invasively model the skin diseases of patients. Using their chips, the firms say it could now be possible to establish a more direct link between lab data and human research, and develop more efficient cosmetic treatments.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment