Ogle Models and Prototypes, the model making, industrial 3D printing and prototyping company has brought its equipment investment, over the past 36 months, to almost £2 million with the acquisition of a new Stratasys Neo450s SLA 3D printer.

The Stratasys Neo450s printer, previously known as the RPS Neo450, prior to Stratasys’ acquisition of RP Support Ltd., offers outstanding part sidewall quality and accuracy over a build volume of 450 x 450 x 400mm. This further enhances Ogle Models and Prototypes’ offering with an increased capacity and the ability to produce higher definition parts with even finer details than ever before. The addition also allows the company to offer a reduced lead time to their customers.

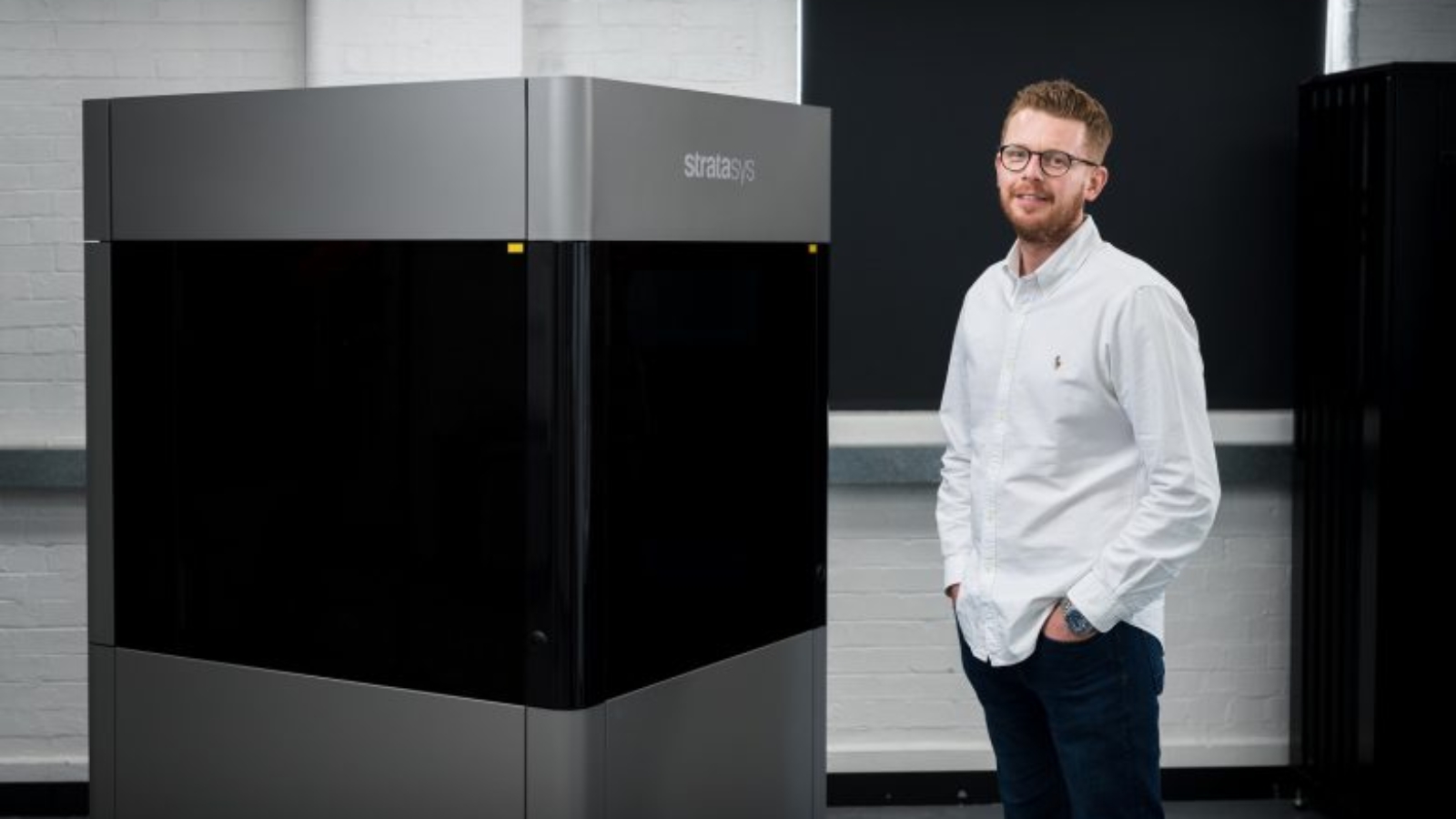

“The acquisition of another market-leading 3D printer underscores Ogle’s dedication to customer satisfaction. The Stratasys Neo450s will enable us to build prototypes, rapid tooling and master patterns with exceptional surface quality. The smaller build area, when compared to our large frame machines, allows us to offer parts with an even faster turnaround,” said Phil Martin, Director at Ogle Models and Prototypes.

Manufacturing on Demand

Based in Letchworth, Hertfordshire, Ogle Models and Prototypes has been at the forefront of design and prototyping since its inception more than 65 years ago, and prides itself on harnessing the latest technologies to cater for evolving customer requirements. The company was one of the first UK firms to install vacuum casting and invest in SLA machines.

“Ogle is at the forefront of producing models, prototypes and low volume production parts, and investments such as this help us to maintain our leading market position. By increasing efficiency and making the continual improvements in quality that our clients have come to expect of Ogle, we are ensuring they return to us time and time again,” said Phil Martin.

The Stratasys Neo450s completes a number of recent acquisitions across the business including an EOS P 770 SLS 3D printer, a second NEO 800 SLA printer and a second Hurco VM30i CNC machine.

You might also like:

Geeetech launches its high-speed THUNDER FDM 3D printer: Geeetech has been working on the technology, which enables the THUNDER to print quickly without compromising the quality of the final part, for two years now, since 2020. According to Geeetech, the printer can reach a print speed of up to 300mm/s with an acceleration of 5000mm/s² for the X-axis, and 4000mm/s² for Y-axis. The company also claims that, with the same model and printing quality, users can save 30%-70% printing time, depending on the complexity of the model.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment