Welsh biotech firms Jellagen and Copner Biotech have joined forces in what the companies are claiming is a “world-first” partnership to combine new bioinks derived from jellyfish collagen with advanced precision software.

Having secured funding of £123,724 from Wales’ business R&D investor scheme, SMART Cymru, the partners are seeking to enhance the compatibility, reproducibility, and precision of 3D bioprinting using Jellagen’s proprietary Collagen Type 0 bioink and Copner Biotech’s advanced algorithm software.

“We are absolutely delighted to partner with Jordan Copner and his team at Copner Biotech,” said Professor Andrew Mearns Spragg, Founder and Chief Scientific Officer at Jellagen. “SMART Cymru has enabled the creation of an exciting collaboration between two high-growth Welsh businesses at the forefront of exciting technological innovation in 3D software design capability and medical tissue engineering.”

Jellyfish collagen bioinks

Jellagen was founded in 2015 with the aim of developing and commercializing marine-sourced collagen for 3D bioprinting applications in the medical and scientific research fields. The company is seeking to build sustainable sources for critical biomaterials that do not harbor the environmental and human health risks of traditional collagen sources.

The firm has been working on the development of its next-generation Collagen Type 0 bioink, derived from jellyfish collagen, and is looking to establish partnerships with medical institutions to investigate the material’s use as a treatment for skin diseases and tissue reconstruction.

The collagen in Jellagen’s biomaterial is extracted from Rhizostoma Pulmo, an ancient species of large jellyfish common to the Irish Sea. According to the firm, Collagen Type 0 has proven to promote anti-inflammatory tissue response that produces fewer side effects than traditional collagens derived from mammals, and demonstrates good compatibility and reproducibility for bioprinting applications.

Jellagen is currently marketing a range of Collagen Type 0 products for research use, and is also developing clinical-grade formulations for therapeutic and medical device applications. The firm’s current products include collagen-based gels, scaffolds, and collagen-coated cultureware plates.

Creating a “paradigm shift” in bioprinting

According to Jellagen and Copner Biotech, their new partnership has “the potential to transform the 3D bioprinting market”, which Verified Market Research’s Global 3D Bioprinting Market Report predicts will be worth £1.4 billion by 2028.

The partnership will see Jellagen’s Collagen Type 0 bioink combined with Copner Biotech’s advanced algorithm software to improve the precision of the 3D bioprinting process.

Manufacturing on Demand

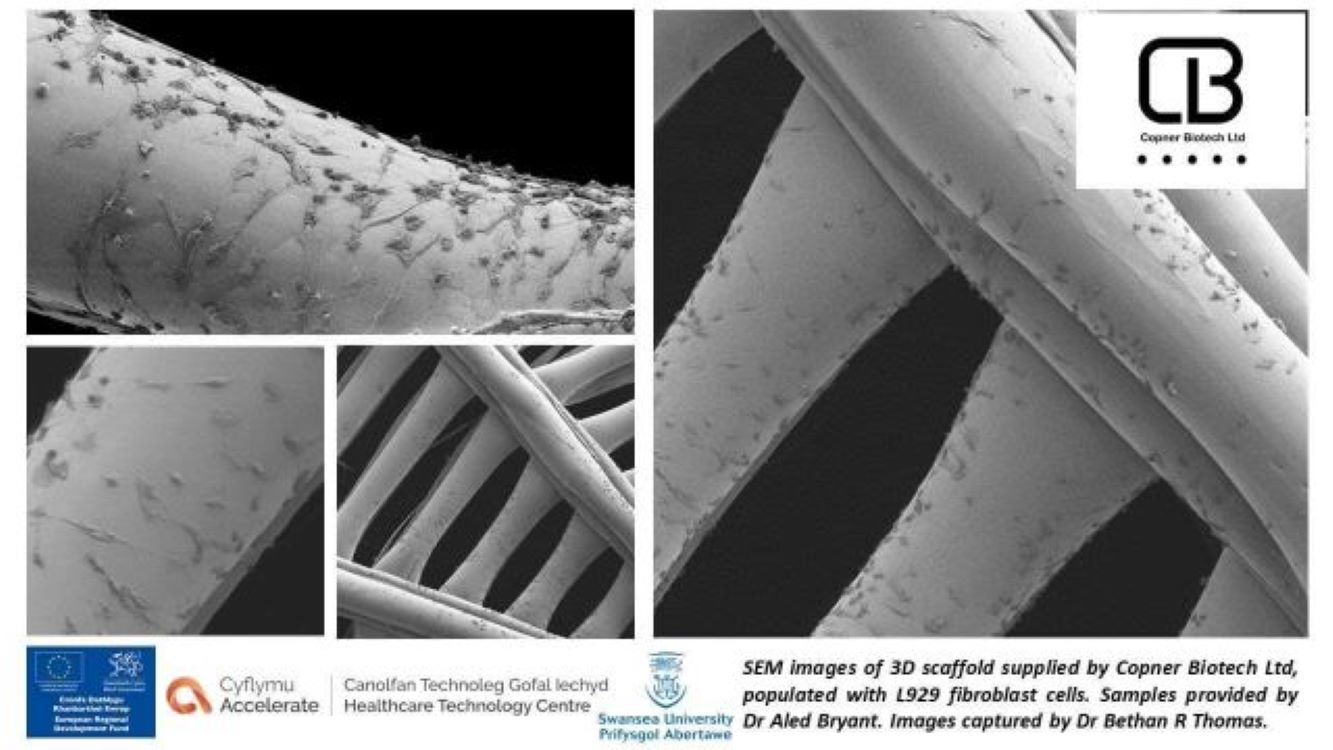

Copner Biotech was founded last year with the goal of creating new software platforms for manufacturing products for applications within the 3D cell culture market, such as cancer research and tissue engineering. The company has since developed a novel software operating platform for the design of cell culture scaffolds that facilitate oxygen and nutrient gradients, and was presented with a GHP International Life Sciences Award for Innovation earlier this year.

On the 1st October, Copner Biotech filed an application with the UK’s Intellectual Property Office to patent the design and manufacturing workflow for the production of 3D Bio Scaffolds with its cell adhesion to scaffold technology. Going forward, and as part of its new partnership with Jellagen, Copner biotech will look to further develop and commercialize its software through mass manufacturing polymer cell scaffolds and other bioprinting products.

“This is a enormously exciting scientific collaboration between Copner Biotech and Jellagen, and a reflection of the increasing significance of 3D bioprinting in the global medical research landscape,” said Jordan Copner, Founder and CEO of Copner Biotech. “Our partnership aims to push the boundaries to advance innovation in biomedical engineering.”

Marine-inspired bioprinting

As 3D bioprinting continues to receive mounting interest and development, scientists are increasingly looking to replicate materials and processes found in the natural world that exhibit desirable properties unobtainable by man-made means. The development of bioinks and bioprinting applications derived from marine sources in particular have garnered much interest, with several research breakthroughs having occurred recently.

For instance, researchers at Rutgers University have 3D printed camouflage-ready soft robots inspired by the adaptable cells found in squid, cuttlefish, and octopuses, while Yamagata Unviersity scientists have developed a 3D printed actuator that could form the basis of a jellyfish-like soft robot.

In June, scientists from Northwestern University discovered a rare type of iron mineral in the teeth of a “wandering meatloaf” mollusk, and set about leveraging the discovery to develop bioinks suitable for 3D printing that mimic the mollusk stylus’ strength, stiffness, and connective properties. Most recently, researchers from Pacific Northwest National Laboratory developed a new seaweed-based bioink that can be integrated with fine mico pigment powders to produce vibrant colors well-suited to artistic applications.

Moving away from bioink development, the hierarchical structure of limpets has been harnessed for the design of 3D printed microneedle patches, and biomimetic cell-like structures with unique energy absorption capabilities have been 3D printed based on the skeletons of cuttlefish. Elsewhere, Lobster shell patterns have even formed the basis of designs for 3D printed concrete structures.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment