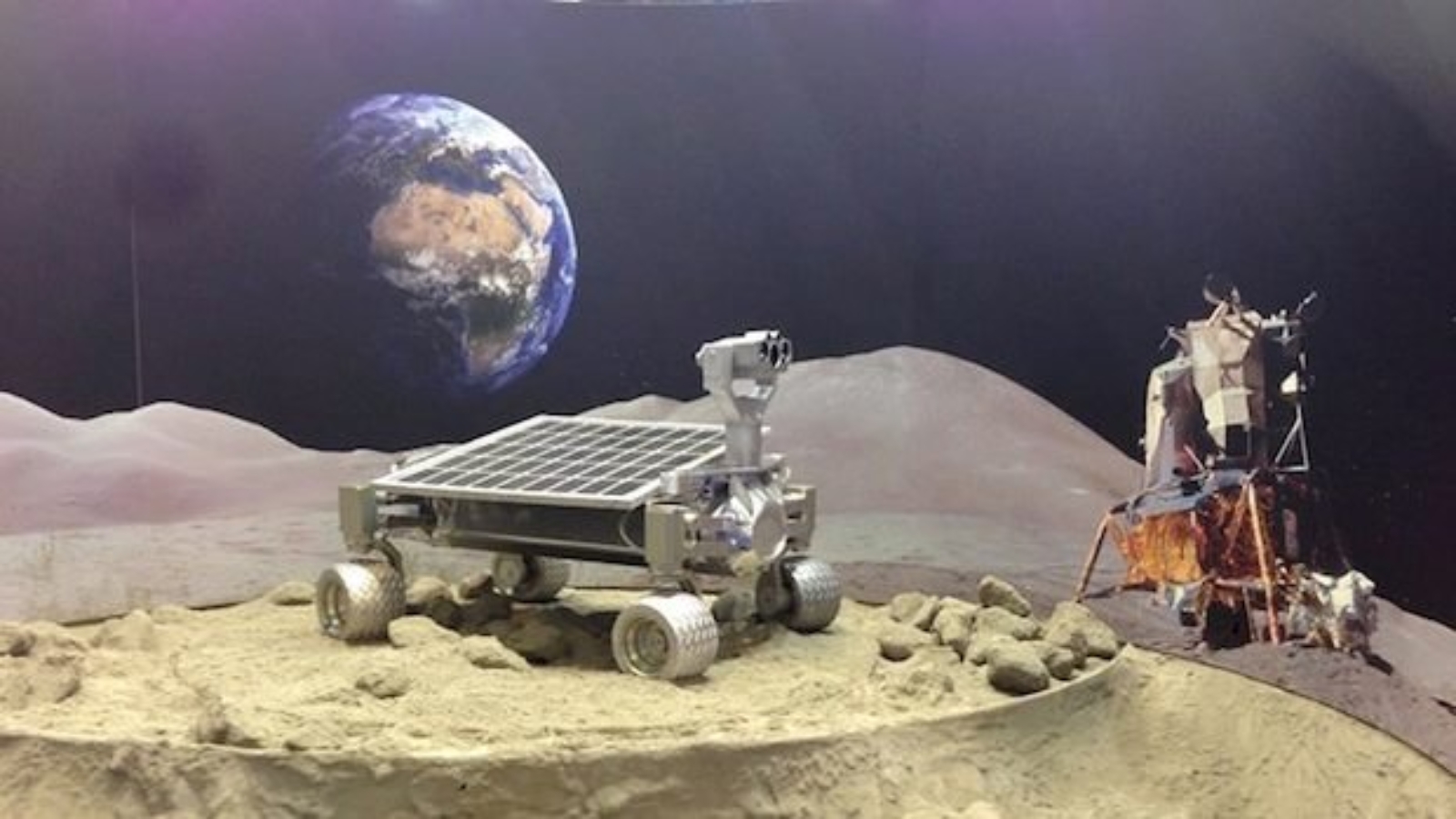

Only 5% of the Moon’s surface has been explored by the human race, and to reach the other 95%, NASA astronauts on the Artemis program are going to need some serious wheels. That’s why Lockheed Martin and General Motors have teamed up to design a next-generation lunar rover, capable of transporting astronauts across farther distances on the lunar surface. While the rover doesn’t need to be lightweight to travel around the Moon, it will certainly have to be extremely lightweight in order to be transported from the Earth’s surface (where it will likely be assembled, until there will be AM factories available in space) to the surface of the Moon. For this endeavor, Lockheed Martin and GM—with both companies already quite familiar with using AM—may want to turn to SLM Solutions. The metal AM hardware manufacturer has built up experience with building both lunar rovers and cars.

Unlike the Apollo days when the rovers only traveled four miles from the landing site, Artemis astronauts will go farther and explore more of the Moon’s surface than ever before to conduct critical scientific research. This type of mobility is a huge step – or a giant leap – toward enabling and sustaining long-term exploration of the lunar surface. The science that Artemis astronauts will conduct will help NASA better understand the fundamental planetary processes underlying our solar system and will help us better understand and protect Earth.

Not only will these vehicles be well-equipped to go the distance, they will also be driver optional. Autonomous, self-driving systems would enable the vehicle to operate with or without humans onboard, and pave the way for future human missions, commercial payload services and enhanced scientific utility. In this case both LM and GM may find some useful collaboration from Local Motors, the company that heavily has used AM to produce the Olli autonomous vehicle. The composites LFAM technologies used for the Ollie could more easily be replicated in orbit-based factories than any traditional manufacturing method.

“These next-generation rover concepts will dramatically extend the exploration range of astronauts as they perform high-priority science investigation on the Moon that will ultimately impact humanity’s understanding of our place in the solar system,” said Rick Ambrose, executive vice president, Lockheed Martin Space.

A Lockheed Martin-GM rover would be able to preposition itself autonomously near a landing site prior to the astronauts’ arrival, and astronauts would have the ability to task the rover from the Human Landing System or the orbiting lunar Gateway to conduct science operations without a driver. This enables NASA to fit more science into a smaller amount of time, and allows us to uncover the critical information that the other 95% of the lunar surface may hold.

Zooming on the Moon

Driving on the Moon is not your average off-roading experience. The new lunar rover concept would be expertly outfitted to drive over rugged terrain in the dark and cold. Unlike Earth and even Mars, days and nights on the Moon are just under 14 days long. The Lockheed Martin-GM rovers would be designed to survive and even operate in the two-week long night that sees temperatures of down to -280 degrees Fahrenheit, and day-time temperatures of 260 Fahrenheit.

“The biggest difference is, when you design for the Moon and for space applications, the force of gravity is different and has to be taken into account,” said Madhu Raghavan, Global Research & Development Group Manager at GM. “There are extreme temperature swings, and the radiation in space becomes a challenge in terms of systems design. You’re also operating in a vacuum and designing your systems to withstand the shock of the actual launch.”

The vehicles’ design would expertly mitigate these challenges. Lockheed Martin has built multiple deep space robotic spacecraft that have gone to the Moon, Mars, Jupiter, Venus, asteroids, comets and other destinations throughout the solar system.

“We’ve led missions to other planetary bodies for decades, building spacecraft that can survive the high radiation environment, cold temperatures, and yet be very light and very reliable,” said Kirk Shireman, vice president, Lunar Exploration Campaigns at Lockheed Martin. “This is what we specialize in, and we are more than capable of meeting and exceeding this challenge for NASA.”

A dynamic duo

With both brains and brawn, the Lockheed Martin-GM alliance brings together innovations from both companies to make transformative vehicles, drawing on strong legacies of engineering and performance from both companies. Lockheed Martin will lead the team by leveraging its legacy and history working with NASA.

“Our goal is to build a vehicle that is affordable, that exceeds our customer requirements, and to do it rapidly. Digital tools are how we achieve that,” Shireman said. “We’ve demonstrated already across programs and proposals the speed, affordability and reliability that digital tools enable, and we fully expect to leverage and expand on that experience with this program.”

Manufacturing on Demand

GM brings to the table decades of experience designing for on and off-road environments, a strong focus on quality and human safety, and a shared mission. “There’s a lot of synergy between our two companies – we complement each other well,” said Jeff Ryder, vice president, Growth & Strategy at GM Defense. “The lunar rover designs for extreme off-road environments have a lot of similarities with our tactical military vehicles on the GM Defense side. It’s great to work with a company like Lockheed Martin who has a shared mission of supporting the warfighter.”

GM brings to the table state-of-the-art battery-electric technologies and propulsion systems that are central to the company’s extensive electric vehicle strategy. Research from the development of battery and power systems for the lunar rover may ultimately spur advances on electric vehicles back on Earth, too.

“Because the operating conditions are so extreme in space, our work on this project will help us make safer and better batteries back on Earth,” Raghavan said. “The Moon and Mars are, of course, totally unstructured, unlined roads. Designing for that environment will ultimately just make our EV capabilities on Earth that much stronger.”

Enabling a celestial human future

As it was during the Apollo era, every minute of the Artemis astronauts’ time on the lunar surface will be carefully planned in order to maximize the scientific value of having humans back on the lunar surface for the first time since 1972.

So, what is NASA hoping to uncover on the uncharted territory that remains of the Moon? The Moon is often referred to as the cornerstone of the solar system. Scientific investigations on the Artemis program will help NASA understand the risks and potential resources of the Moon’s South Pole, where they hope to establish the Artemis Base Camp concept by the end of the decade.

“The technology has evolved so much in the last 50 years, to the point where we can now use autonomy for these vehicles to aid in the astronauts’ missions,” Shireman said. “Autonomy will enable these rovers to carry tools and samples, and allows the crews to do more in the time they have there on the surface.”

To achieve our ultimate goal of utilizing the resources on the Moon to sustain a human presence, Shireman says we’ll need to have a reliable way of transporting those resources. This is the first major step in that direction. “I’ve worked on many space programs in the past, but this isn’t just another space mission,” said Ryder. “It’s the return to, and permanent habitation of the Moon. It’s not just cool or interesting –it’s historical. It’s a major milestone in human activity in space.”

According to Raghavan, he’s seen a major influx of job applicants for open positions on his project team. “This is the stuff you dream about as a kid in science class,” he said. “People want to be part of this.”

Other scientific activities that surface mobility could enable include field geology, sample collection and return, and deployed experiments. These investigations are conducted in the hopes that they may increase our understanding of how the Moon formed and evolved, how it interacts with the Sun, and how water and other resources arrived at the Moon, and how they are transported and preserved.

These are all questions that, once answered, will help us sustain life on the Moon. The Lockheed Martin-GM team stands ready to autonomously chauffeur the astronauts to the dark regions of the Moon to advance our human future in space.

“I always think about alliances, and how you have to start with something real,” Ryder said. “As we go do this, it’ll likely lead to additional opportunities. It’s a great pathway going forward, and I’m sure there will be more opportunities for our two companies to come together to further human spaceflight.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment