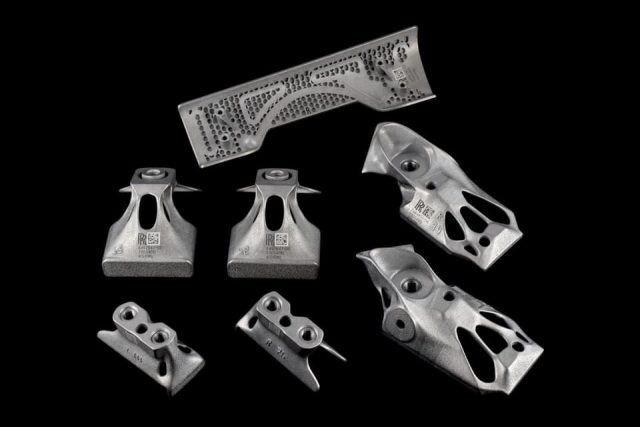

Sometimes a photo is worth more than a thousand words. This is definitely one of those times: Rolls Royce (part of the BMW Group, one of the most active in implementing AM for production) just showed off a large batch of DfAM optimized and serially 3D printed automotive metal parts.

Manufacturing on Demand

Rolls Royce had revealed a few years back that it had already produced over 10,000 parts by AM for its Phantom models alone. As recently as a few months ago, the luxury brand revealed it used AM to expand the body of the new Rolls Royce Ghost Extended without sacrificing internal comfort.

Some really cool features visible in the parts also include the 3D printed brand name (Rolls Royce) and a QR code, along with numbers to identify the specific, unique, part: something that can only be achieved with digital manufacturing (and only with AM to this degree of serial production, as no subtractive method could ever compete).

The images show several different types of parts, which are then welded to the car’s chassis. This is already well beyond a case study and we can certainly speak of a true production application. Granted, Rolls Royce’s numbers are not comparable to those of mass-produced cars but this is yet another major step in the direction of serially 3D printed automotive parts nonetheless.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment