CD3D Medical, the R&D arm of Polish 3D printing news provider CD3D Sp. z. o. o. (Centrum Druku 3D) has created an Open 3D Bioprinting Cluster in Lodz. Part of the Bionanopark laboratory complex, this facility, according to the company, is one of the largest of its kind in Europe, housing 21 SKAFFOSYS 3D bioprinters developed especially for this purpose.

Paweł Ślusarczyk, President of the Board and Business Development Manager at CD3D, is Project Director for the cluster. Speaking to 3D Printing Industry, Ślusarczyk gives further detail about this landmark installation and the developing SKAFFOSYS 3D bioprinter brand.

Outsourcing 3D R&D

The CD3D Open 3D Bioprinting Cluster is the product of two to three years studying the medical 3D printing market. Though various institutions are using 3D bioprinting for regenerative experimentation, Ślusarczyk explains that CD3D noticed a gap for off-site facilities. “Right now the situation on the market is that if you want to have anything bioprinted and tested, you need to buy a bioprinter and have [your] own laboratory,” Ślusarczyk explains.

“In [our] case – you can outsource everything or part of your research to us and scientists at the Laboratory of Molecular and Nanostructured Biophysics in Bionanopark, who are essential partners of the project.”

At present, CD3D Medical is conducting projects for existing partners at the cluster, though the topic of these remains classified. As Ślusarczyk points out though, the cluster is co-located with the Laboratory of Individual Medical Implants, “so the general direction of most of our own projects is rather obvious,” he adds. Two specific R&D focus areas are bioinks research and medical applications including “implants made out of hydrogels or liquid or semi-fluid polymers, artificial earlobes etc. [and] new food research.”

The SKAFFOSYS 3D bioprinter

At the core of the Open 3D Bioprinting Cluster is a hub of SKAFFOSYS 3D bioprinters. “[…] to our knowledge,” Ślusarczyk adds, “there is no such installation anywhere – or at least no one officially presented it yet. So it is probably the biggest bioprinting cluster in number of the machines.”

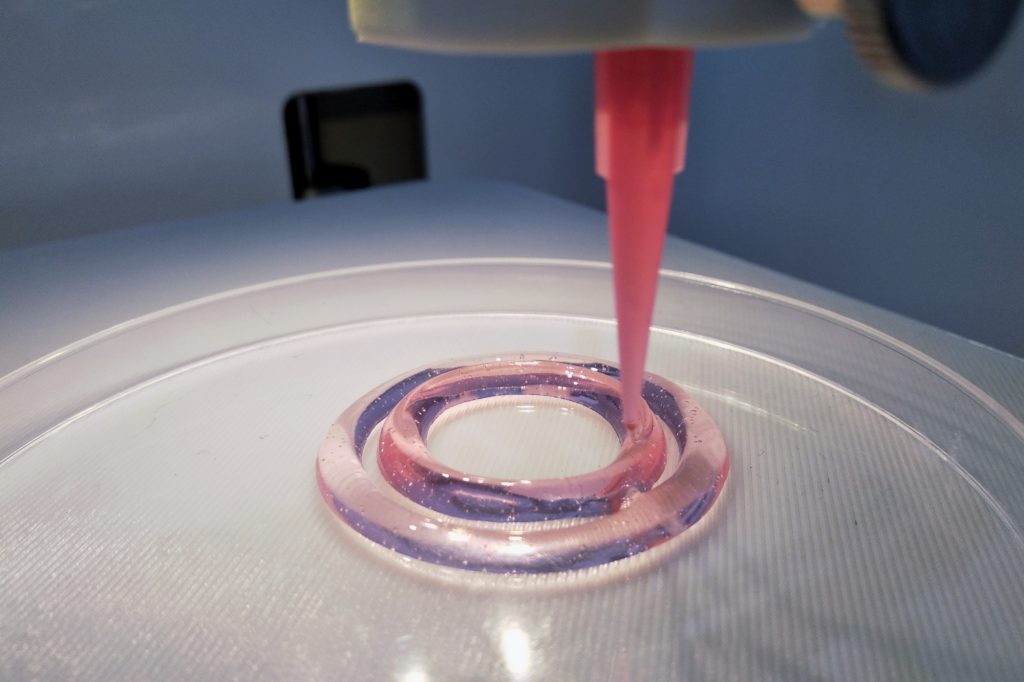

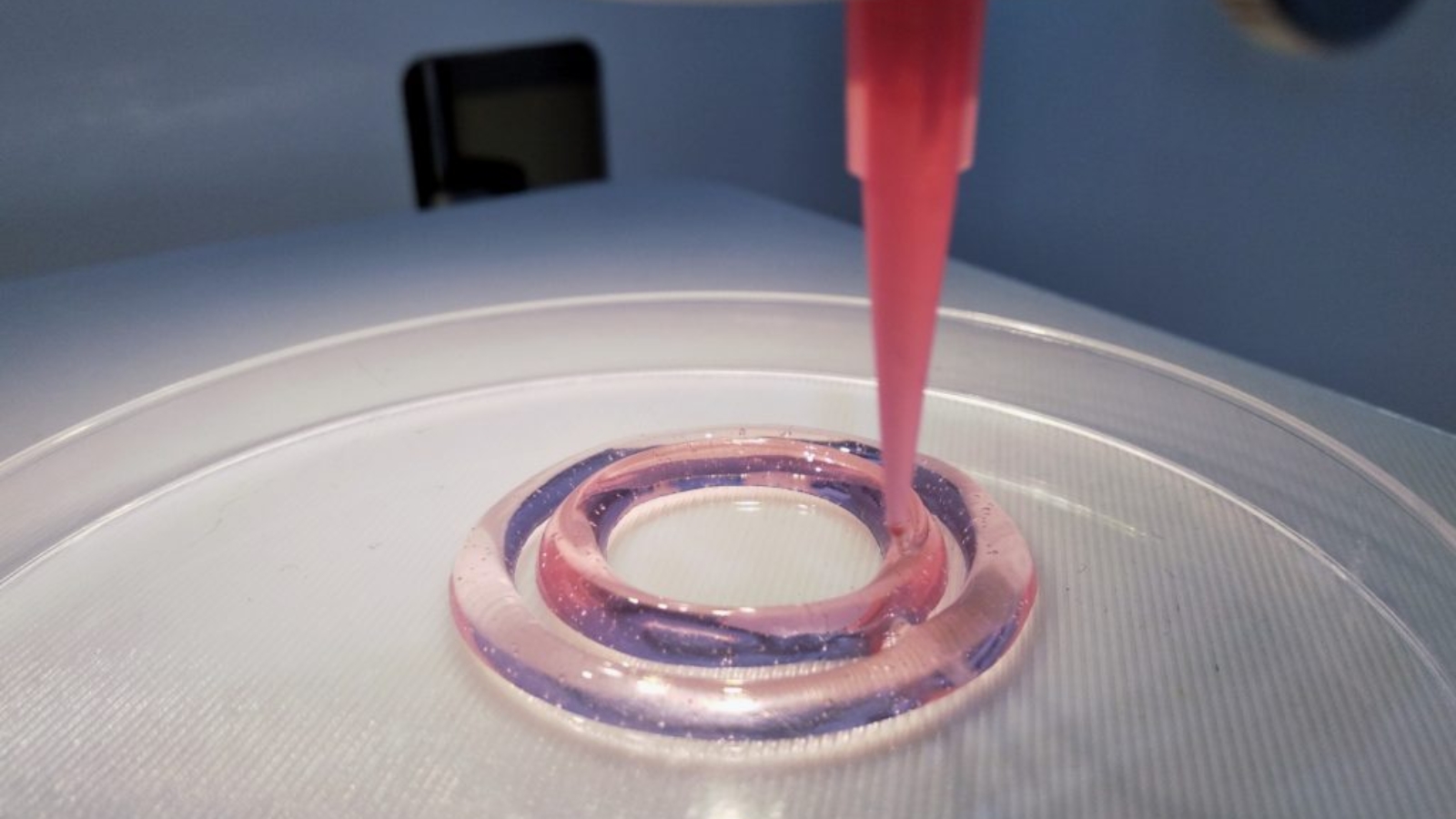

The 21 machines installed in this facility are the only ones so far that have been manufactured. They were developed for CD3D Medical by a team of engineers, and are continually being updated with new features. A Lite version of the 3D bioprinter is offered on a commercial basis. A syringe-based extrusion system, the SKAFFOSYS Lite has a maximum build area of 170 x 125 x 80 mm. Though made specially for the cluster, SKAFFOSYS is intended to operate as another brand entirely independent of CD3D Medical.

Manufacturing on Demand

“As CD3D Medical we want to focus on research and bioprinting services […] SKAFFOSYS is / will be a separate brand, although we are the ones that co-designed it and brought to life,” comments Ślusarczyk. “We don’t want to be seen as manufacturers but science and research bureau, focused on bioprinting technology.”

The 3D bioprinting industry

Without a doubt, 3D bioprinting has become a significant area of interest to the medical industry. This year, global healthcare company Johnson & Johnson invested millions of euros into the development of a 3D Bioprinting Centre of Excellence at Trinity College Dublin.

Launched in 2017, BiOSpace is a facility in Manchester, UK, that gives researchers pay-per-access usage of its facilities and equipment, including 3D bioprinters.

To name just a few of the current competitors on the market, CELLINK, ROKIT, EnvisionTec and Aether all currently provide 3D bioprinter hardware, and in some cases materials and software. Looking toward the future however, Ślusarczyk thinks “there is still a very long way to go.”

“The bioprinting industry is in my opinion at the very same stage as was original 3D printing industry back in the 90’s… However all the reports and predictions show that it will grow to enormous proportions – we just have to do our thing and be patient.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Beau Jackson

Leave A Comment