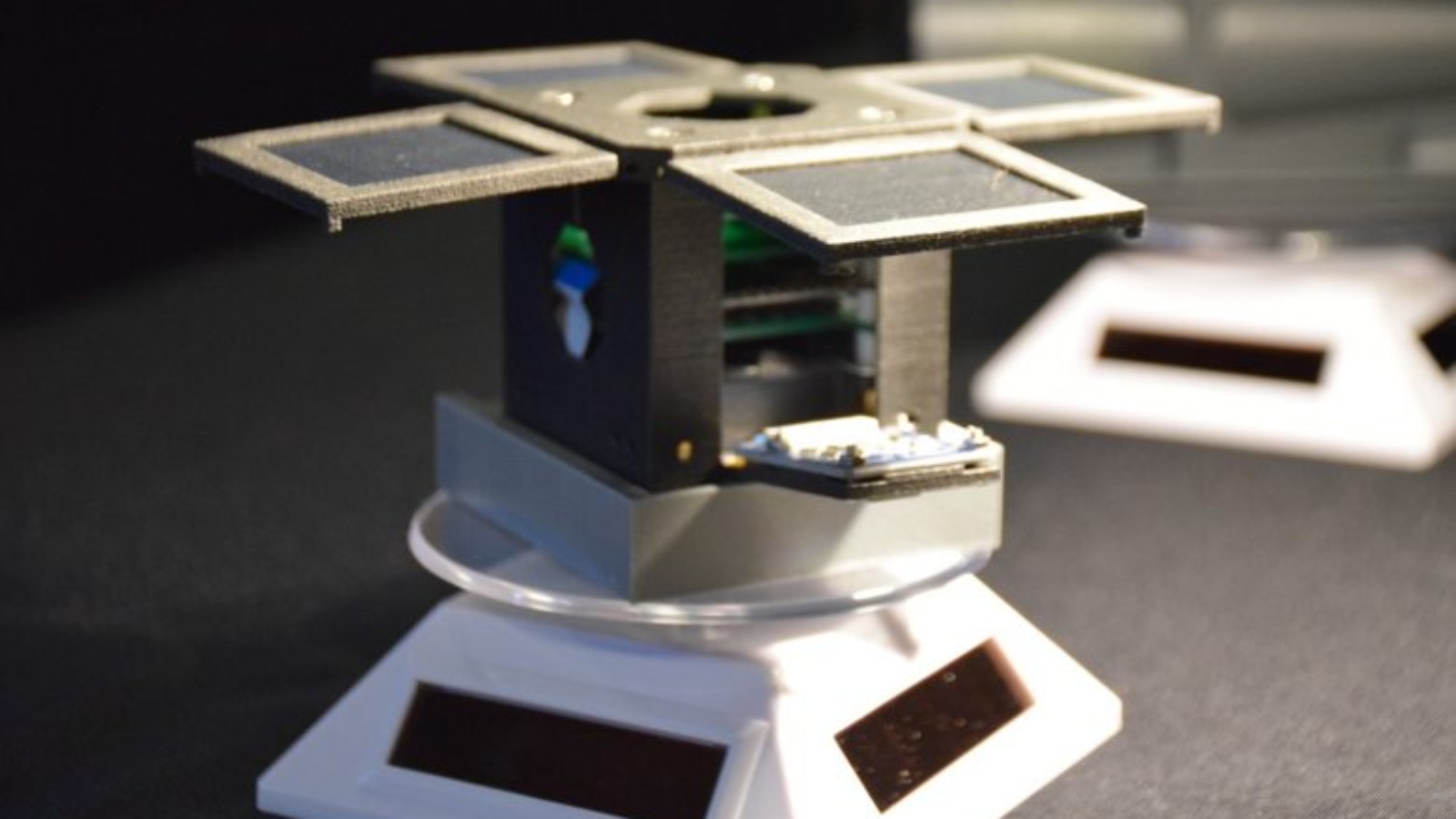

US-based CRP USA manufactured three engineering models for Mini-Cubes. It is the first time that entire PocketQube functional flight-ready prototypes are manufactured using a Carbon-reinforced composite material – Windform XT 2.0 – and the laser sintering process

Recently Joseph Latrell, CEO of Mini-Cubes, LLC, and his team started a project based on the engineering of a new 1P PocketQube flight-ready, named Discovery. The aim of the project is the creation of a constellation of PocketQube satellites for monitoring a specific Earth’s resource, water.

Latrell turned to CRP USA for the manufacture of the entire satellite frame via Laser Sintering process using one material from the Windform TOP-LINE family of composite materials for Laser Sintering, the Carbon fiber reinforced Windform XT 2.0, created by Italy-based CRP Technology.

The main challenges were related to the small dimension of the satellite and to the material – since it was the first time that an entire satellite would be built from a Carbon-composite material.

Joe Latrell commented: “Discovery is a PocketQube satellite. These spacecraft are amongst the smallest with 50mm x 50mm x 50mm internal volume. Our particular satellite is a demonstration of what can be done for remote sensing of Earth’s resources on that scale. The challenge with something so small is to fit the electronics, camera, and radio system into it.

Manufacturing on Demand

The assignment was tough – the Windform parts in the Discovery would be mission-critical.

As Joe Latrell clarified: “This was the first time an entire satellite would be manufactured from a material like WindformXT 2.0. Performance is everything. If any of the parts fail, it would result in complete failure of the spacecraft.”

CRP USA manufactured three 1P PocketQubes functional prototypes for the Mini-Cubes: two for testing and one for flight.

“Joe’s team brings a unique challenge as they are packing a lot in a small package. Our team was able to use our experience with Windform to help move the project forward,” stated Stewart Davis, Director of Operations at CRP USA.

“We have run quite a few tests with many more on the way,” Joe Latrell added. “So far we have load tested to over 20 Kg. The material has been vibration tested to NASA GEVS-7000 specifications, subjected to a near-vacuum to simulate the conditions in Earth orbit, and thermally tested from +50c to -40c. Windform XT 2.0 has passed every test we threw at it.”

“The next step for us is to test the satellite on orbit. This will be the final validation for our process. The plan is to launch sometime in Q2 2021,” he concluded.

You might also like:

Elon Musk wants you to help create more 3D printed parts for his rockets: If this sounds like a dream job for most people involved with advancing AM, it’s because it probably is. In the LinkedIn ad, SpaceX stresses that the company “was founded under the belief that a future where humanity is out exploring the stars is fundamentally more exciting than one where we are not.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment