Italian design firm Barberio Colella Architetti and architect Angelo Figliola proposed a project called Urban Dunes to help manage the extreme climate in Abu Dhabi. Figliola will work with Barberio Colella Architetti to 3D print Abu Dhabi’s sustainable urban bioclimatic shell using binder jet technology.

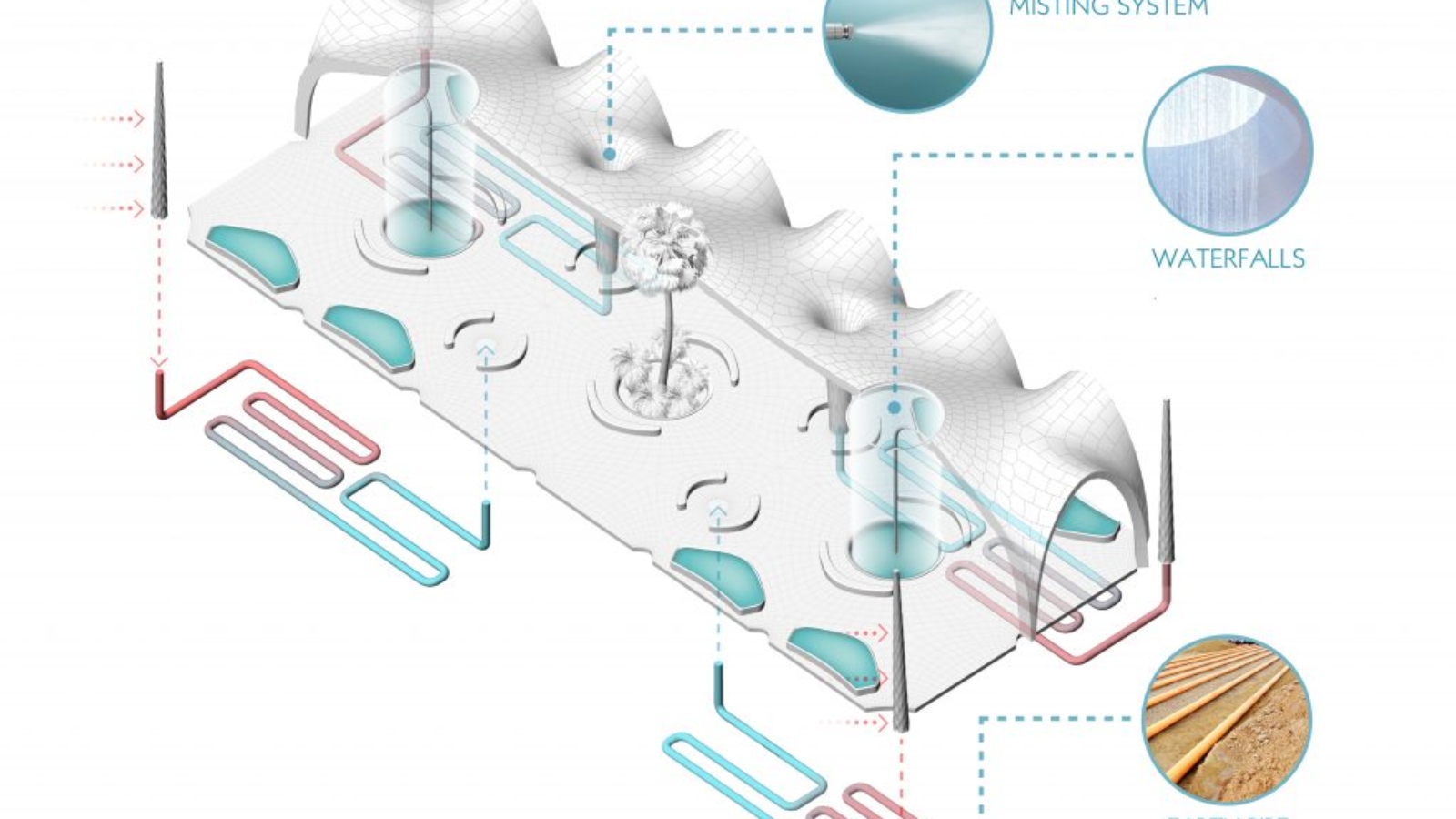

The ultimate goal of the project is to lift a thick layer of sand and create an “oasis” in the city through artificial dunes. Urban Dunes will use cost-effective passive cooling and low-tech active systems that require the least energy and can keep indoors cool without wasting resources.

The process of building urban dunes

Urban Dunes’ design proposal stems from admiration, Barberio Colella Architetti and Figliola’s consciousness is the climate background of Abu Dhabi and the traditional architecture of the UAE. In the proposal, the vaulted ceiling is composed of several three-dimensional blocks, which are formed by stacking heavy units together. Local sand in Abu Dhabi is used as raw material and forms the sandstone with binder jet technology.

The “Cool Abu Dhabi Challenge” competition won honors for Barberio Colella Architetti and Figliola. The Abu Dhabi City Department of Transportation promotes the competition, which focuses on cooling urban spaces in a practical but sustainable way.

Using 3D printing to Combat the Earth’s temperature

The application of the 55 cm thick 3D printed vaulted roof will prevent the urban space from overheating due to its high thermal mass. The environmental analysis of the vernacular shading device in the sand library also shows that it can fully protect and shade Urban Dune. In addition, the space under the enclosure is actively ventilated by a low-tech HVAC system, which is a cost-effective alternative to battery-powered systems.

The sand itself will be mixed with heat-reflective cooling pigments, which can increase the reflectivity of the surface and reduce the accumulation of surface heat. A series of small grounding pipes further reduce the temperature of the vault. These grounding pipes flow coolant inside the shell wall.

A constant temperature of approximately 14°C underground will also play a role in the passive cooling structure. These systems will work together to reach a relatively cool Global Thermal Climate Index (UTCI) of 26°C in August, the warmest month in Abu Dhabi.

Sustainable 3D printing in construction and other fields

This month, the Italian 3D printer manufacturer WASP collaborated with the Rossana Orlandi Gallery in Milan to showcase Gaia, a 3D printed eco-house made of sustainable materials.

Gaia is manufactured using the company’s CRANE WASP 3D printer and uses soil as the main printing material. The outer shell of the building was printed in about ten days and consists of a wall of 20 square meters and 40 cm thick. Gaia aims to integrate a natural ventilation system and a thermal and acoustic isolation system. WASP claims that the biological building has the least impact on the environment and has great scalability.

MRO service provider Etihad Engineering has partnered with German 3D printer manufacturers EOS and BigRep elsewhere in Abu Dhabi to open an additive manufacturing plant in Abu Dhabi. This collaboration resulted in the region’s first 3D printing laboratory, which was approved by the European Aviation Safety Agency (EASA) to produce aircraft parts using powder bed fusion technology.

Leave A Comment