Researchers from the University of Cambridge have developed a method of 3D printing a new generation of sensors with tiny, transparent electronic fibers. This fiber is 100 times thinner than human hair and can be used to make devices that can smell, hear, and touch. The research results are published in “Science Progress”.

When studying phenomena particularly related to the current COVID-19 pandemic, the report’s first author, Andy Wang, Ph.D. from the Department of Engineering, University of Cambridge, tried to measure the passage of normal breathing, rapid breathing, and simulation. The amount of breath moisture leaking from the mask. cough. To this end, Dr. Yan Yan Shery Huang, also from the Department of Engineering, led the team to 3D print composite fibers made of silver and/or semiconducting polymers.

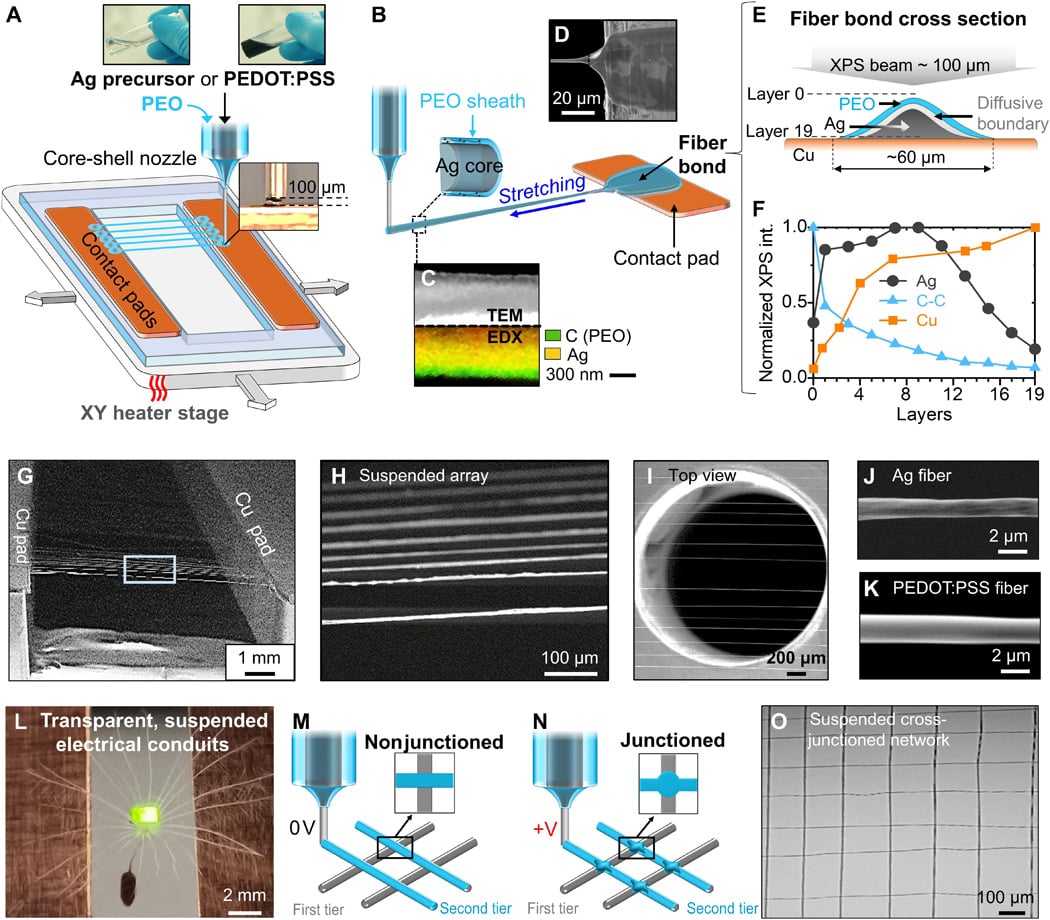

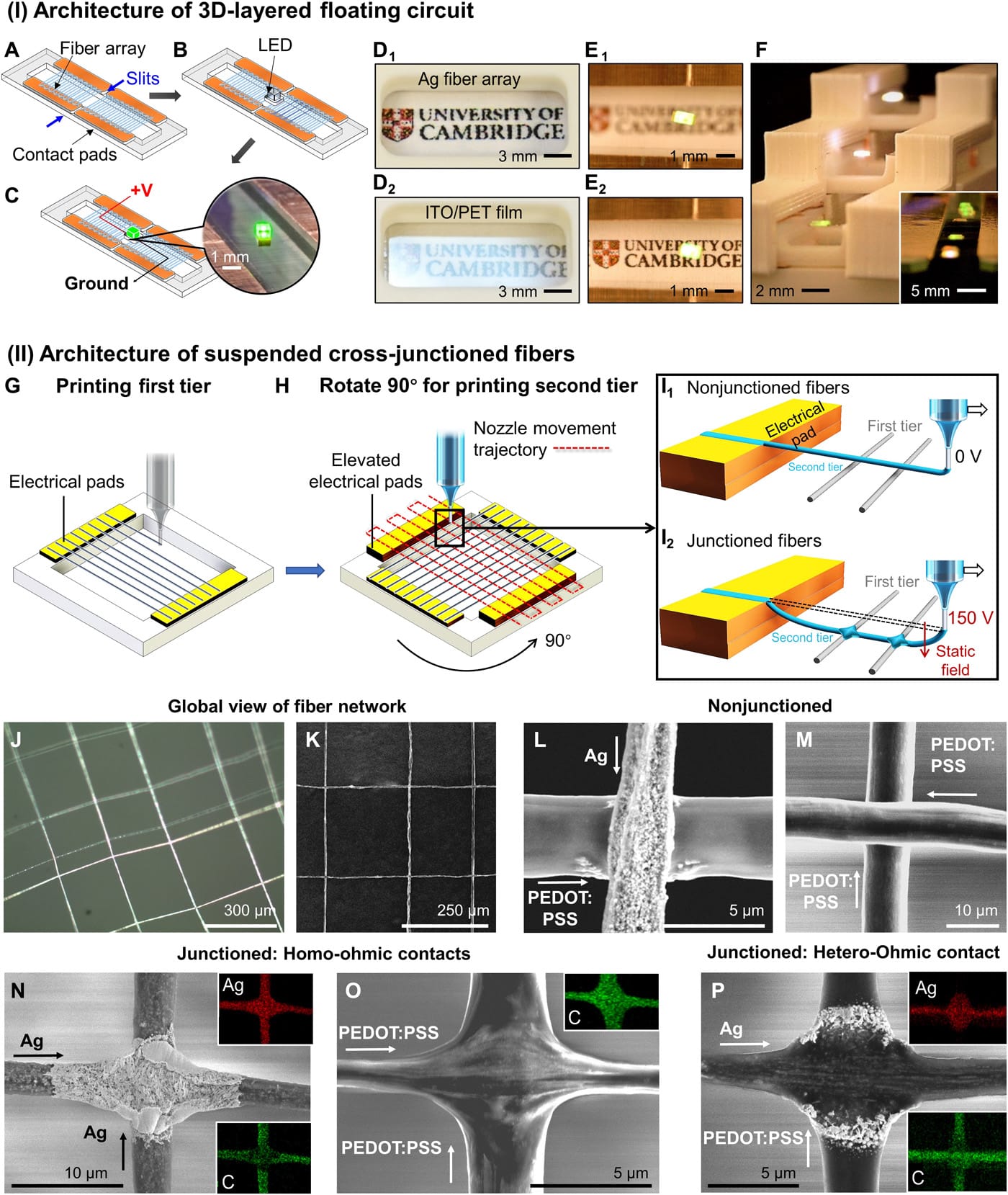

The process developed by the researchers is a form of direct ink writing, in which a polymer of silver or poly(3,4-ethylene dioxythiophene) polystyrene sulfonate (PEDOT:PSS) is passed through an ion gun etching the fiber into the pad. Fiber enters the mat. The fiber stretches between the two copper pads, bridging the two electrodes.

To demonstrate the application, the team created a sensor to measure the moisture leaking through the mask. The sensor can determine that the most leaking part from the fabric or surgical mask is from the front, especially when coughing, while the most leaking part of the N95 mask is from the top and side. Make sure to wear all masks properly to help reduce the flow of exhalation.

“Sensors made from small conducting fibers are especially useful for volumetric sensing of fluid and gas in 3D, compared to conventional thin-film techniques, but so far, it has been challenging to print and incorporate them into devices, and to manufacture them at scale,” Dr. Huang said. “Our fiber sensors are lightweight, cheap, small and easy to use, so they could potentially be turned into home-test devices to allow the general public to perform self-administered tests to get information about their environments.”

Uniquely, these sensors can be used to make non-contact, wearable, portable breathing sensors that can be connected to smartphones to collect breathing patterns as well as sounds and images. This technology is beyond the scope of respiration sensors, and the team suggested that biocompatible fibers with a size similar to biological cells can allow them to guide cell movement and actually measure the process in the form of electrical signals.

Because the optical fiber is so small that it cannot be seen with the naked eye, the team was able to 3D print the optical fiber to float the LED lights in the air. As shown in the picture above, the LEDs are suspended in a transparent array made of silver fibers. The researchers’ future work includes multifunctional sensors for mobile health monitoring and bio-machine interfaces.

As detailed in our electronic product 3D printing series, this is only a small part of the research that may eventually lead to 3D printing of complete functional objects in a single construction process. Currently, only a few commercial companies provide the basis for such technologies, including Optomec. This research shows that not only is it possible to 3D print such a complex device, but it can also advance existing technology by further reducing electronic devices.