High-performance sports car manufacturer Porsche has partnered with machine tool manufacturer TRUMPF and auto parts company MAHLE to provide 3D printed pistons for the engine of its flagship 911 supercar.

Using laser metal fusion (LMF) 3D printing technology, automakers’ engineers have been able to optimize the structure of auto parts under load. AI-led additive manufacturing also enables Porsche to integrate cooling ducts into the “top cover” of the component. Compared with the company’s mass-produced products, these features not only reduce the weight of the piston by 10%, but also increase the horsepower of the engine by 30 BHP.

“Thanks to the new, lighter pistons, we can increase the engine speed, lower the temperature load on the pistons and optimize combustion,” explained Frank Ickinger from the advance drive development department at Porsche. “This makes it possible to get up to 30 PS more power from the 700 PS Biturbo engine, while at the same time improving efficiency.”

Additive Manufacturing of Porsche Pistons

The use of 3D printing instead of traditional production methods to manufacture pistons allows Porsche to focus on the use of materials in the areas where the parts are subject to the greatest external force. This technology makes the piston much lighter than current supercars, and generates 30 horsepower from its 3.8-liter twin-turbocharged engine, raising it to 730 BHP.

“3D printing allows us to construct items bionically, and produce extremely lightweight, yet high-strength components, which are now helping us to cut out a huge amount of weight in the case of our piston design,” explained Dominik Abele, Project Leader, Corporate Advanced Engineering at MAHLE. “We can now run the engine at a higher RPM, and this generates more power.”

Emphasis is placed on the outer shell of the piston or its “skirt”, and the point where it intersects with the “connecting rod” of the part, called a “marble”. Integrating cooling channels into components reduces the temperature in these areas and improves the overall efficiency of the engine. In addition, the use of AI to optimize the shape and basic topology of the piston can minimize the need for support materials. As a result, only the hole of the part “wrist pin” needs to be removed later in the process.

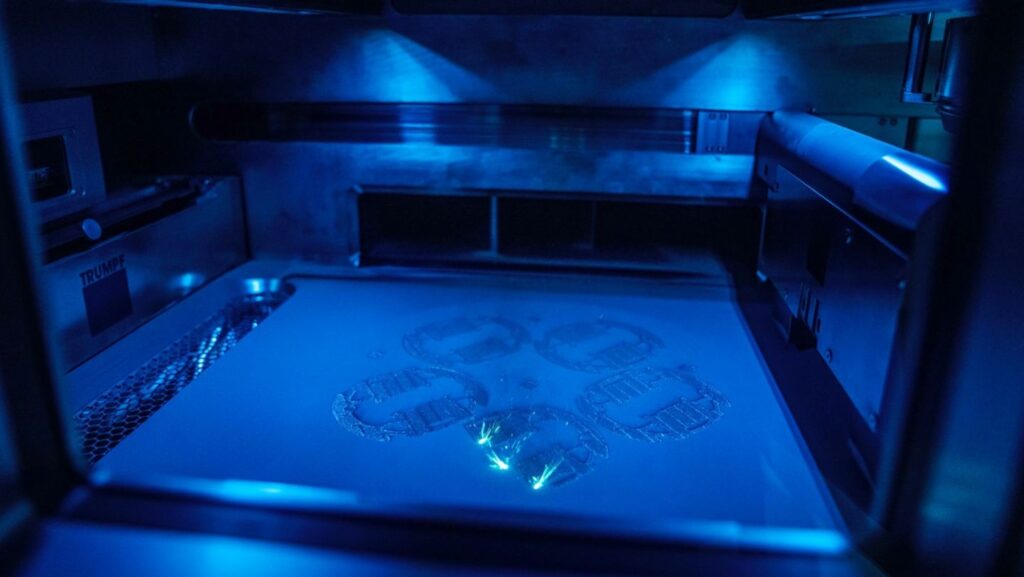

Porsche produced six prototype pistons using high-purity M174+ aluminum alloy powder manufactured in-house by MAHLE and 3D printed them using the TRUMPF 5000 system. In a process that took a total of 12 hours to complete, 1200 layers of the part were constructed using laser melting 3D printing technology to shape the powder into the final product. Then, the printed piston undergoes the same preparation steps as a conventional piston: machining, measurement and testing.

Verification of newly developed additive parts

After the parts are configured, they enter Porsche’s standard “pulse” test to check their wall thickness. The parts are also inspected for “tear” to ensure that their marbles will not become thin under load. Not only has the 3D printed piston passed, but further bench evaluations will now continue, which are designed to measure its long-term durability. To test its consistency, these tests included 135 hours of full-load operation at various speeds and 25 hours of drag load.

“The results are in, and all the pistons passed the tests. Next, it’s on to the bench test, a 200-hour endurance test under the toughest conditions,” added Ulrich Kunzmann, Head of Prototype Manufacturing at MAHLE. “The positive results confirm the great potential of 3D printing, especially for high-performance, small and limited runs, and when it comes to prototyping.”

Although testing is still ongoing, Porsche has not yet committed to installing 3D printed parts in its commercial vehicles. Nevertheless, the company did say that it has played a safety role in the design of the piston, and the part can still be further optimized to improve performance. “We always make sure to make mistakes in safety. Our simulation results show that the weight of each piston may save up to 20%.”

“The torsional vibration damper can then be made smaller, thereby making the engine even more free-revving. Increased thermal resistance due to the lower temperature also permits higher combustion pressures and even more advanced ignition timing — both factors that increase power and efficiency.”

Therefore, 3D printing is still an important part of the company’s path forward and is excited about the technology’s potential in the industry. “I believe that additive manufacturing will become an important part of automotive R&D and production,” Aikinger concluded. “At the latest in 10 years.”

Additive manufacturing in the automotive industry

Although Porsche does not guarantee the use of its newly developed pistons in production cars, it has 3D printed a series of end-use parts in the past. For example, in February 2018, the supercar manufacturer began printing spare parts for its rare and classic cars. It was then announced earlier this year that it would 3D print personalized bucket seats for 40 prototypes for use on European race tracks.

Other car companies have also benefited from additive manufacturing, such as the startup Czinger, which will launch its first 3D printed supercar 21C in 2021. Using 3D printing, this $1.7 million car will reduce weight and cost. Compared with traditional production methods, it has greater benefits and benefits from reduced manufacturing time.

At the same time, APWORKS, an additive manufacturing consulting company, has 3D printed metal parts for the latest Bugatti Chiron supercar. The tailpipe assembly is made of titanium to make it more lightweight and resistant to high temperatures.