Rounding-off 2020, December saw the launch of various dental 3D printing products, as well as novel production processes, and the completion of significant business moves by Desktop Metal and Stratasys among others.

December’s additive dental releases

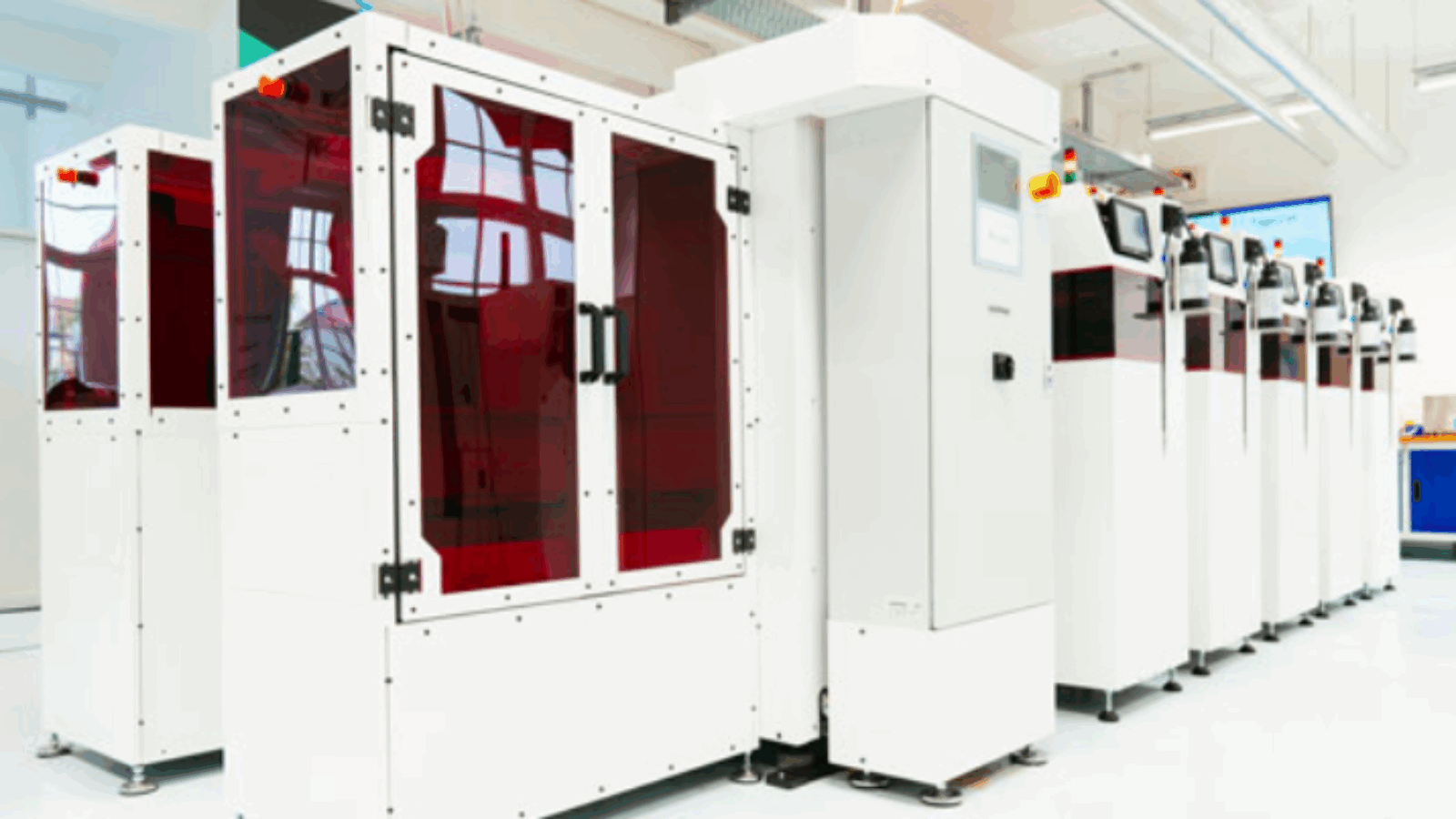

The first of the month’s dental launches came from German 3D printer producer Rapid Shape with its RS inline machine. Rapid’s new system, which is designed to print high volumes of transparent aligner models, ejects finished parts automatically, potentially enabling users to fabricate over 4,000 units per day.

Elsewhere in the additive orthodontic sector, polymer resin manufacturer Graphy launched its Tera Harz dental 3D printing material brand. The new range of customizable resins were developed using a unique compounding technology, that allows adopters to tailor them to the needs of their specific dental prosthetic.

3D printer manufacturer Formlabs, meanwhile, added two new materials to its orthodontic portfolio: a Permanent Crown Resin and a Soft Tissue Starter Pack. The latter was specifically designed to enable dentists to create patient-specific resins, that yield more accurate models and ultimately accelerate their implantation.

Stratasys, Desktop make business moves

Desktop Metal finalized one of the year’s biggest 3D printing deals in December, when it concluded its merger with Trine Acquisition. Once it had been signed off by Trine’s shareholders, the agreement saw Desktop gain $580 million in funding, and become listed on the New York Stock Exchange (NYSE).

Stratasys also pulled off a significant business move during the month, acquiring DLP 3D printer manufacturer Origin in an agreement worth up to $100 million. According to Stratasys’ analysis, the deal could provide it with a method of building its medical business while increasing its annual revenue by $200 million by 2026.

“We believe Origin’s software-driven system is the best in the industry at combining high throughput with incredible accuracy,” said Yoav Zeif, CEO of Stratasys. “When combined with our industry-leading go-to-market capabilities, we believe we will be able to capture a wide range of in-demand production applications.”

3D printing’s flurry of investment activity continued into mid-December, with more than $14 million being spent on the shares of additive firms in a matter of days. While Arkema acquired resin manufacturer Colorado Photopolymer Solutions (CPS), Evonik secured a minority stake in Chinese SLA printer producer UnionTech.

The Chattanooga-based Branch Technology raised the largest amount of funding during December when it closed an $11 million funding round led by rental firm EquipmentShare. Following the investment, the company has now raised over $22 million, to develop and expand on its construction 3D printers and product lines.

Manufacturing on Demand

“We are excited about the addition of EquipmentShare to our strategic team of investors,” said Platt Boyd, CEO of Branch Technology. “Together with past investment from Brick & Mortar Ventures, Bonaventure Capital, LaunchTN, and Metaprop, we are collectively revolutionizing the construction industry.”

New 3D printing platforms launch

Canadian soft material producer Structur3d left it late in 2020 to launch its new machine, but it may well have been worth the wait. With its desktop Inj3ctor platform, the company combined 3D printing and injection molding, with the aim of accelerating the research, prototyping, and production of rubber parts.

“As a team of scientists and chemical engineers, we took a materials approach to 3D printing and expanded the printers’ material capabilities beyond standard plastics,” said Charles Mire, CEO and Co-Founder of Structur3d. “Our Inj3ctor platform demonstrates how AM can lead the way toward the factory of the future.”

Austrian optical systems developer In-Vision, meanwhile, announced the launch of its most powerful DLP 3D printing light engine to date. The HELIOS UV light projector was built to achieve the highest possible illumination intensity, which could enable it to provide faster cure times, and compatibility with a greater number of resins.

Redwire and 3D Systems’ aerospace parts

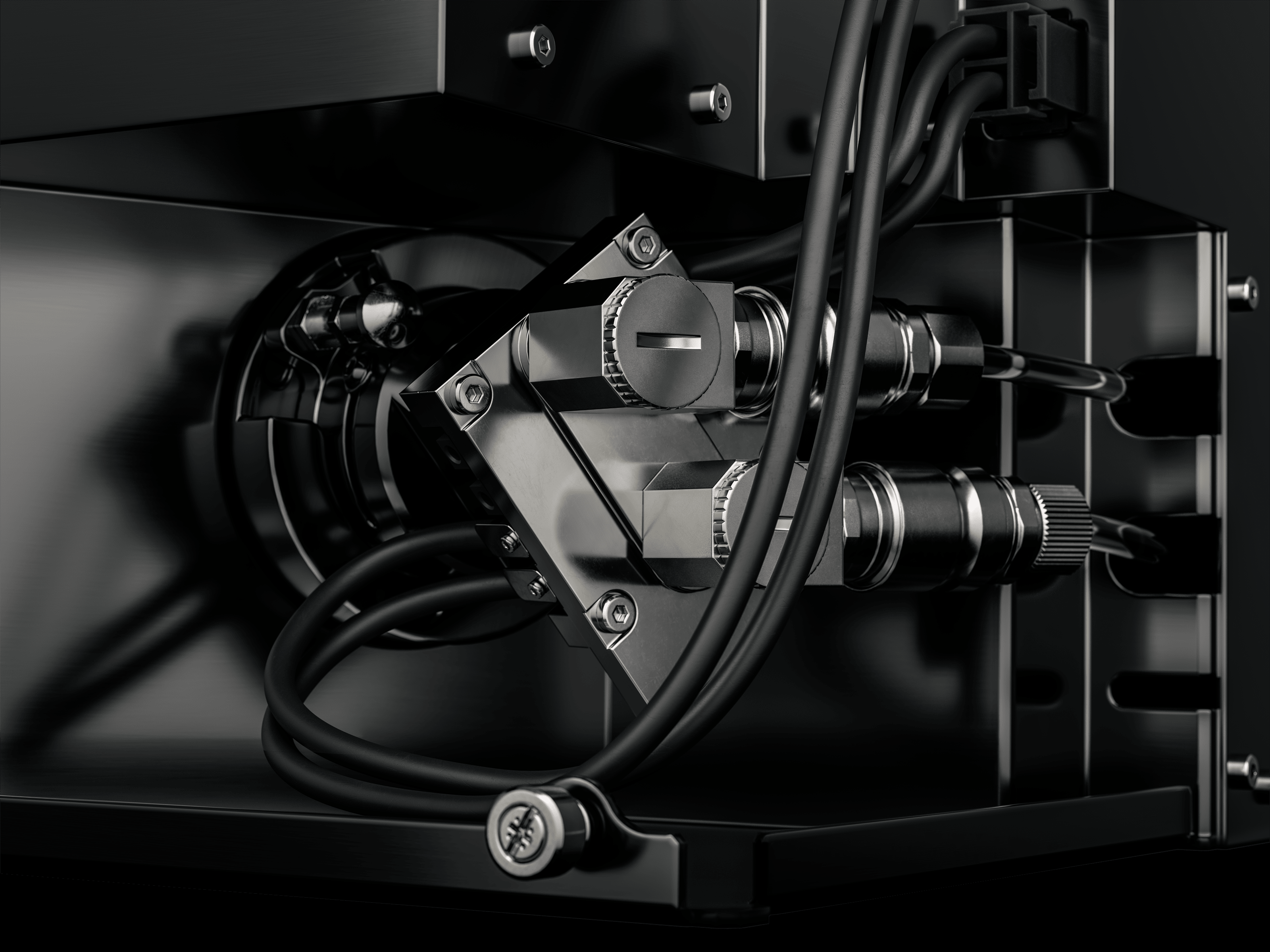

Towards the end of the year, 3D Systems partnered with the European nuclear research group CERN to develop 3D printed cooling parts for the Large Hadron Collider. Working alongside the Dutch physics organization Nikhef, the firm fabricated a set of custom titanium cool-bars for particle detection experiments.

Mission control systems specialist Redwire also made space-related progress in December, when it 3D printed its first ceramic parts in orbit using its Ceramic Manufacturing Module (CMM). The components, which were produced onboard the ISS, included material test coupons, as well as a single-piece ceramic turbine blisk.

“This is an exciting milestone for space enabled manufacturing and signals the potential for new markets that could spur commercial activity in low Earth orbit,” said Tom Campbell, President of Made In Space. “Redwire is developing AM processes on orbit that could yield sustainable demand from terrestrial markets.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment