Since the advent of the sewing machine in 1790, clothing manufacturing has had a distinctly hands-off approach, relying on machines and technology to efficiently produce apparel on a mass scale. Before the Industrial Revolution, clothes-making was much more laborious, costly, and time-consuming and, as such, the average individual usually only owned between two and four outfits (today, Americans buy about 68 new garments per year). This important milestone in apparel manufacturing kickstarted two centuries of advancements that have led us to a fashion industry revolution based entirely on modern technology.

3D printing technology has made a splash in almost every type of industry you can imagine, and the fashion industry is no exception. The use of 3D printing technology in the fashion industry is gaining traction as designers and clothing producers discover the benefits of this technology. 3D printers can be used to create fantastic 3D printed fashion with shapes and geometries never made before, but they can also be used for prototyping purposes, as well as making the clothing production process much more sustainable.

3D Printing

Prototyping and Tooling

Creating prototypes and tools for manufacturing are two of the most common uses of professional 3D printers, and the fashion industry is no exception to this. 3D printers also encourage designers to take more design risks, since they can quickly assess the viability of their designs. Prototyping different design iterations in this way allow designers more time and freedom to come up with new innovative designs.

Customization

3D printing is also becoming essential in the design and development of clothing and footwear, as it allows producers to prototype in real-time, instantly tweaking and altering in a way that’s a lot more efficient than it once was. 3D printing is also hugely impactful to footwear – New Balance and Reebok both use 3D printing to print components of their shoes, including laces and soles.

Sustainability

3D printing technology in the fashion space is also gaining traction for sustainable fashion, as more designers and brands are beginning to seek sustainable methods to create their collections.

A great example of this is the innovative Spanish fashion brand ZER. They use additive manufacturing throughout their designing and creation process as a means to be a sustainable force in the fashion industry. They use 3D printers to design their specific patterns and then print only the amount of product that they need. This allows them to cut back on wasting resources for each garment, and ensuring that their manufacturing process is not harmful to the environment.

Fashion Accessories

Instead of 3D printing full items of clothing, 3D printing is also used to supplement parts of a whole design, like embellishments, accessories, and buttons.

Small end-use accessories can be easily assembled in just minutes or hours using 3D printing. 3D printing materials with a flexible nature, such as TPU, can be used to add accent pieces or unique embellishments onto the garment themselves. 3D printing can also be used to create costume jewelry with complex geometric shapes.

From the materials used in the finest luxury watches to the way we try on clothes, technology has dramatically affected the way we shop for, wear, and produce clothing. Here are other specific technologies that have changed fashion.

Augmented Reality (AR) and Virtual reality (VR)

Retailers in all categories know that finding ways to bridge the gap between eCommerce and real life is key to a successful business model in the 21st century. One way they are doing this is by employing virtual reality (VR) and augmented reality (AR) to help shoppers visualize and try on clothing online.

For example, platforms such as Virtusize, Ditto, and Virtooal provide integrations that let shoppers virtually try on apparel while shopping from their computer or smartphone. In no realm is this technology more apparent than eyewear, as most of the leading glasses retailers now offer impressive virtual try-on options that let you visualize frames on your face.

Wearable Technology

One of the most obvious examples of fashionable technology is the emergence of wearable devices like smartwatches and fitness trackers. While these devices in and of themselves have been around for a while, an emerging trend in the industry is a stronger shift in focus to fashion. By integrating precious metals, high-end materials, and even gemstones, techy startups are now putting activity trackers and sensors into stylish pieces of jewelry, especially trendy rings, bracelets, and watches.

Tech-Focused Sapphire Crystal

Brand-new materials, from high-tech fibers to specialty precious metals, have had a massive impact on all facets of fashion. While most of the high-end watch and jewelry manufacturers have remained relatively low-tech in terms of digital integrations, that could soon change with the advancement of a new glass that could turn a classic-looking Rolex into a work of technical brilliance.

Tech-focused Swiss watchmaker Winwatch recently developed a way to embed smart payment technologies into their sapphire crystal, equipping traditional-looking wristwatches with the latest tech, including contactless payments.

All-New Precious Metals

Just because names like Apple and Samsung are often thrown around when discussing watches and tech, it doesn’t mean the legacy Swiss makers will be left in the dust. One of the ways these high-end manufacturers are keeping their timepieces up to date is by perfecting the materials they use in the production process.

From Hublot’s innovative Magic Gold – branded as the “first scratch-resistant 18-karat gold” – to Omega’s Liquidmetal that’s three times as hard as stainless steel, the world of men’s luxury watches will never look quite the same.

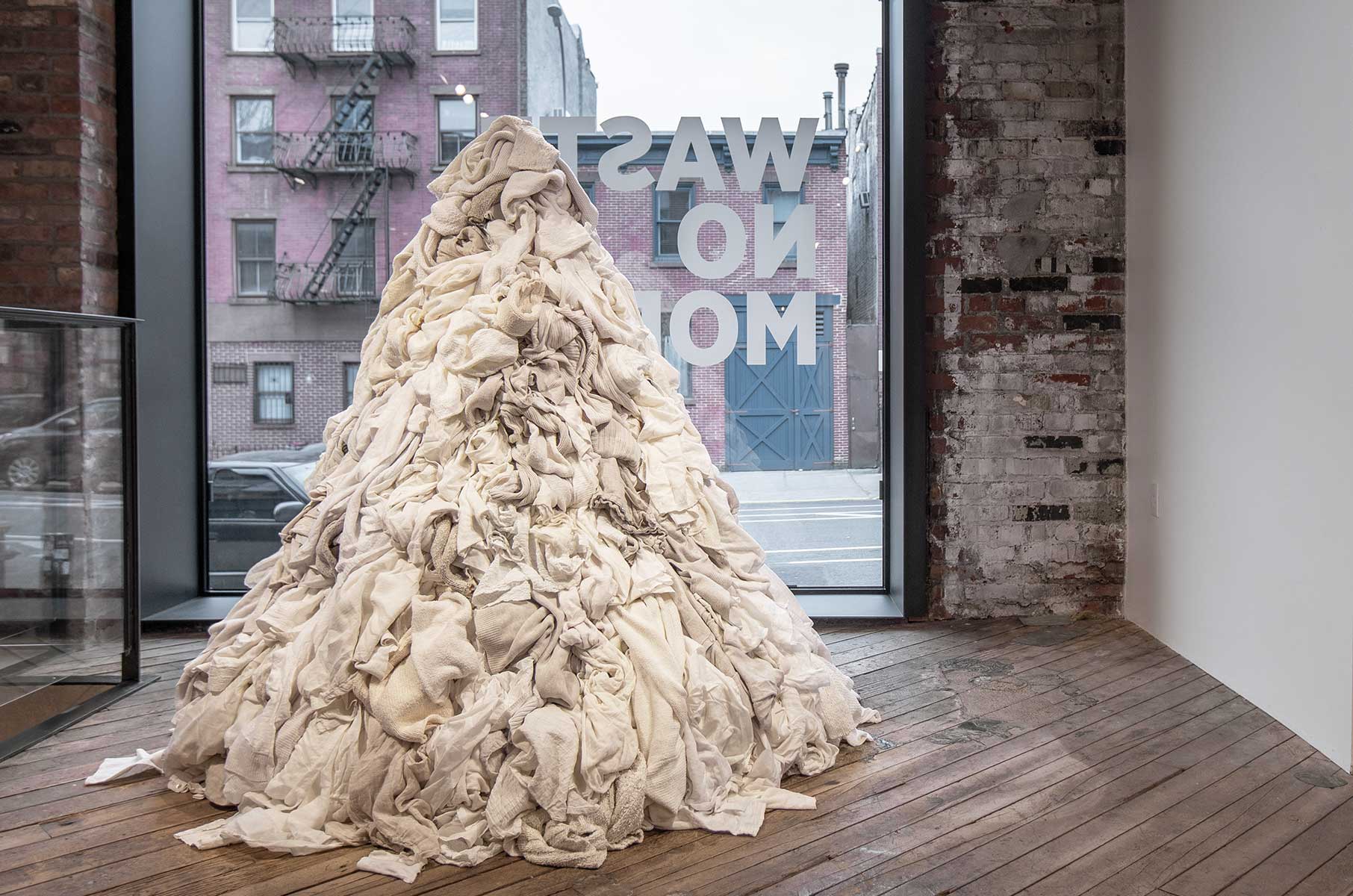

Recycled Fibers

Just as watchmakers are upgrading their metals, apparel brands are upgrading their fibers and fabrics. With consumers demanding sustainability across the entire supply chain, it’s no longer enough to call basic fabrics eco-friendly. Instead, companies are developing brand-new fibers out of discarded or biodegradable materials. From French footwear maker VEJA’s ultra-popular sneakers made of plastic bottles to the upcycled oyster shell textiles used by brands like SiiZU and Mountain Khakis, we’ll see a lot of new ultra-sustainable fibers that go far beyond cotton and wool.

High-Tech Fabrics

In addition to brand-new takes on natural fibers, the fashion industry has also seriously shaken up the way they produce synthetic ones. New fabrics featuring unique blends of materials are coupled with specialized treatments to offer amazing properties that make them quick-drying, less absorbent, moisture-wicking, better at regulating temperature, and great at helping to control odors. The tech fabric takeover is perhaps most obvious in the activewear and outdoor categories, with companies developing new options that ensure comfort while being active.

Smarter Inventory Management

As eCommerce has grown into a mega-industry, we’ve seen inventory management platforms improve significantly. One of the ways this helps shoppers and retailers is by improving the accuracy of the information, including whether or not an item is in stock. On top of that, these high-tech systems are able to effectively track products as they move along the fulfillment chain, which means shoppers and suppliers can track their orders in real-time, improving customer experience and enhancing internal processes.

Although we don’t know exactly where the fashion industry is headed, we know one thing for sure: technology will be at the forefront of its next great era. Whether in design, manufacturing, modeling, or sales, technology has always impacted the way we make and wear clothes. We expect to see a totally different fashion industry in the coming decades – and, hopefully, one that’s leaner, more sustainable, and all-around better for customers.