Andiamo, a UK-based MedTech company specializing in 3D printed orthotics, has been crowned London’s most innovative tech company. It was voted first place in the inaugural London Tech 50, a ranking of the city’s most exciting technology companies. The list is established by BusinessCloud, a business tech media company headquartered in Manchester.

Voters and panelists were swayed by Andiamo’s cloud-based platform for designing and delivering 3D printed orthotics for disabled children using AI technology and Big Data. “We’re very proud to be named Top Tech company in London,” commented Naveed Parvez, CEO of Andiamo. “Especially as London is becoming Europe’s Tech Hub. O&P is always viewed as medicine’s poor relation so it’s great that we have an Orthotics company being recognized in this way.”

Andiamo received the award after having appointed a new Chief Commercial Officer in Hugh Sheridan, the former CEO of Algeos, a global orthotics company, and material supplier. Sheridan was brought to lead the sales, marketing, and education efforts as the company continue to roll out its orthotic delivery platform across the globe. Parvez continues: “Bringing Hugh in as our CCO at this point is perfect timing as we start to deliver High Quality, Safe, Low-Cost 3D printed Orthotics to the O&P industry.”

“I’m very excited at how we can educate the benefits of Andiamo Devices so all orthotics can benefit from happier patients and happier payers.”

The inspiring story of Diamo

Andiamo was founded in 2014 by Naveed and Samiya Parvez, and Lee Provoost, two years after the Parvez’ son Diamo passed away from complications attached to his cerebral palsy. He died at nine years of age, and endured intense pain and suffering due to his condition.

Using a back brace, Diamo’s hardship could be alleviated, supporting his posture and assisting his day-to-day experience. However, the process of getting a custom-made brace for Diamo was difficult, without a guarantee of success. Diamo would have to sit still for hours to allow plaster to gain an accurate mold of his body. The orthosis would take three months to arrive, and sometimes it would need to be sent back for adjustments.

The reduced quality and longer wait times in the orthotic and prosthetic industry is the result of a low number of clinicians, Samiya Parvez told Business Cloud: “At the last calculation I think about 2.1 million people were going through the orthotic services in the UK and there’s less than 300 orthotists who are prescribing them. And not all of them are full-time.”

Providing 3D printed orthotics for millions of children

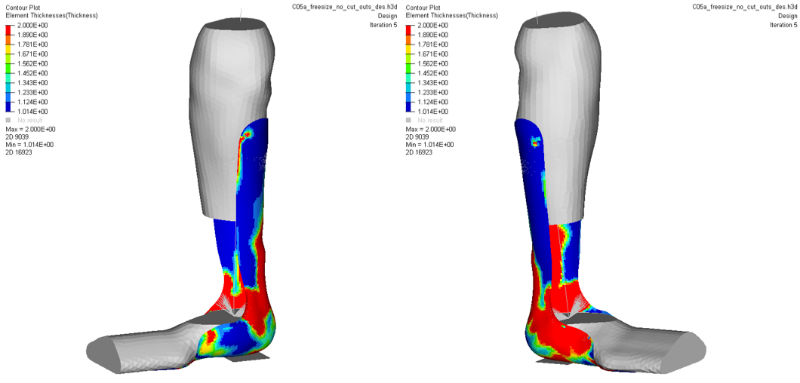

Inspired by the plight of Diamo, Andiamo intends to improve and accelerate the process of designing and manufacturing custom-made splints and braces to support the spine and limbs of disabled children. It provides a platform for orthotists to upload a scan for a prescription 3D printed orthotic device. The scan is reviewed by Andiamo using machine learning and artificial intelligence in order to 3D print a “precision wearable” Ankle-Foot Orthosis (AFO).

Manufacturing on Demand

The AFO is said to be 60 percent lighter than a standard polypropylene device, with a reported first-time fit rate of over 90 percent, thanks to the AI technology. It takes two weeks for the device to be 3D printed from scratch and delivered to the patient. Currently, the product range is limited to 3D printed paediatric AFOs but the product roadmap includes orthotics, seating and prosthetics.

In 2016, Andiamo launched the first iteration of its 3D printed AFO to test with clinics, before entering the market for the UK and Scandanavia in 2018. The company plans to establish delivery points in Saudi Arabia, USA and across Europe over the next 12 months. To date, Andiamo has helped a total of 80 people with their condition, and plans to open a new clinic in central London to help the company achieve 10 million positive outcomes by 2030. Its orthotic technology attracted a combined £1.7 million investment from NCL Technology Ventures, Alfabeat investments and WeWork in a 2018 seed round. The company has received further funding from the European Commision and Innovate UK, an R&D and technology accelerator.

Sheridan concludes that “The Andiamo Team have quietly taken 5 years to build a platform that is able to deliver some of the highest quality Orthotics I’ve ever seen.”

“However, the real opportunity for our industry are the benefits of the devices that the platform and manufacturing technology, can deliver. That brings huge clinical and commercial benefits.”

3D printed orthotics and prosthetics

Many companies have used 3D printing to produce orthotics, prosthetics, and other medical wearables, like the San Francisco-based UNYQ, and ActivArmor, a manufacturer of 3D printed orthoses headquartered in Colorado.

However, Andiamo’s offering has attracted a great deal of attention thanks to its AI software. Not only has it been named the most innovative tech company in London against established tech brands like Deliveroo, Monzo, and DeepMind, it has also won the 2017 WeWork Creator Award, and was highlighted by 3D Printing Industry as a startup to watch in 2018.

Consisting of a team of 30 engineers, even Naveed Parvez is taken back by the company’s remarkable ascent: “3D printing experts started coming to us and saying ‘We’ve never seen what you’ve done before,’” Naveed told The Guardian. “We had Google ringing us up for advice. That’s when we realised that this tiny little team with this crazy idea had suddenly become a world leader by accident.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Anas Essop

Leave A Comment