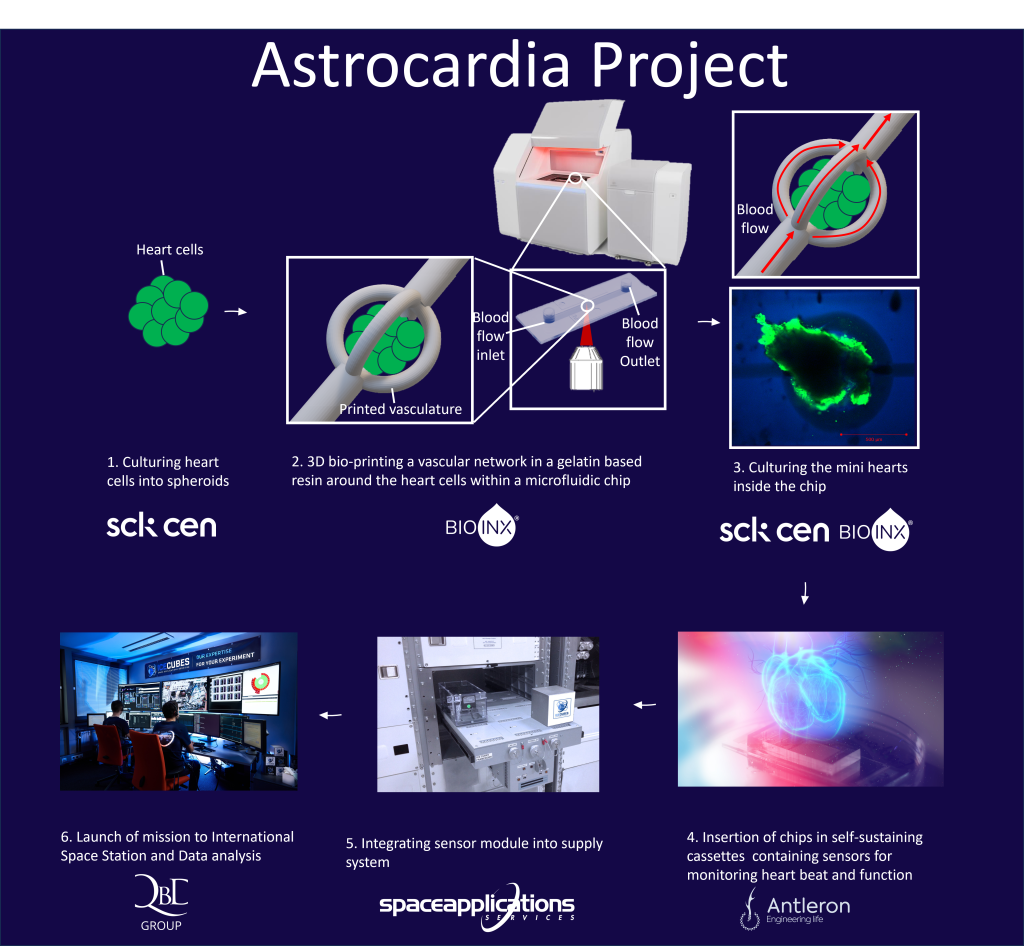

Five Belgian companies and research centers are collaborating as part of the AstroCardia project to 3D print an artificial heart and circulatory system which will be sent to space.

The ‘heart-on-a-chip’ is being developed by Space Application Services, SCK CEN, QbD Group, BIO INX and Antleron, and will be sent to the International Space Station (ISS) in 2025.

According to the AstroCardia researchers, it is practically impossible to conduct in-depth examinations on a living human heart. Therefore, the team will 3D bioprint a miniaturized human heart and artificial circulatory system to enable more in-depth research into the heart’s aging process.

By sending the 3D printed heart to orbit, it is hoped that scientists will be able to better study this process, given that the organ ages 20 times faster in space than on earth.

“Our heart changes as we age. It slowly gets bigger and stiffer, the arteries calcify and the pumping power deteriorates,” explained Space Applications Services researcher Hilde Stenuit. “In space, factors such as stress, microgravity and radiation cause those aging processes to occur 20 times faster. So in space, we are speeding up time. And that gives us the unique opportunity to obtain research results that we simply cannot obtain here on Earth. The platform we will develop will allow research into the mechanisms that drive cardiac aging.”

According to Stenuit, this research will be fully automated and can be operated remotely.

Sending a 3D printed heart to space

During the 3D printing process, heart muscle cells are 3D printed onto a chip measuring a few square millimeters.

The AstroCardia team states that specialist material is essential when 3D bioprinting the miniature heart models. This includes a 3D bioprinter with micrometric precision, living stem cells and ‘bio ink,’ the latter of which is being supplied by Belgium start-up BIO INX.

This ‘bio ink’ includes biomaterials and stem cells that can develop into any possible cell in the human body, the researchers claim. These cells then divide and organize themselves to create a developing human heart model – or ‘organoid.’

An artificial circulatory system is used to feed the heart with stimuli, oxygen and nutrients until it matures and becomes functional. At this stage, the scientists can conduct relevant testing, with the main tests set to be conducted onboard the ISS in 2025.

“The miniature heart, which is barely a chia seed’s size, faithfully mimics its human counterpart. The innovative technique would make it possible to better investigate cardiovascular diseases and test out some potential medicines,” commented Dr Kevin Tabury, a radiology expert at SCK CEN.

Manufacturing on Demand

Dr Tabury added that the team can also personalize the 3D printed hearts using a patient’s stem cells. This would allow the team to effectively grow a miniature version of a patient’s heart, something which would represent “a great leap forward in personalized medicine” according to Dr Tabury.

Space-based heart research

Once launched to the ISS, the heart-on-a-chip devices will be kept alive for at least six weeks, and will be monitored in real time.

The 3D printed organ models will then be returned to Earth, where researchers from pharmaceutical manufacturing company QbD and the nuclear research center SCK CEN will analyze them in detail.

Through this space-based experiment, the AstroCardia partners hope to investigate whether the exposure of the developed cardiovascular system to the space environment can be applied as a scientific model of heart aging.

“With this project, we are looking beyond the horizon. We are already concerned today with the problems society will face tomorrow. A healthy heart is important not only for those currently suffering from cardiovascular disease, but also for healthy astronauts exploring space,” added QbD CIO Martijn Reniers.

3D printing organs

This project reflects ongoing efforts within the additive manufacturing industry to 3D print functional organs.

Last month it was reported that a team of scientists from the University of Sydney and the Children’s Medical Research Institute (CMRI) at Westmead have leveraged 3D photolithography to produce functional 3D printed human tissues that accurately mimic an organ’s architecture.

The researchers utilized bioengineering and cell culture techniques to instruct stem cells to become specialized. These specialized cells can then form organ-like structures. Looking to the future, the researchers will work to develop this technique to advance regenerative medicine and pursue novel treatments for a range of diseases.

Elsewhere, researchers at Utrecht University developed an ultrafast volumetric 3D bioprinting method last year that successfully fabricated working livers. Utilizing visible light tomography, this method enabled the successful 3D printing of miniature stem cell units by making the cells “transparent.” This allowed the cells to retain their resolution and ability to perform biological processes.

These liver units successfully performed key toxin elimination processes mimicking those that natural livers perform in the human body. The researchers claimed that this methodology could open up novel opportunities for regenerative medicine and personalized drug testing.

You might also like:

Researchers 3D print innovative non-invasive devices to detect and monitor diabetes: Through the utilization of 3D printing technology, the researchers crafted a portable device with the ability to analyze glucose and lactate concentrations present in sweat samples. Documented in Elsevier and with backing from the Telangana State Council of Science & Technology (TSCOST), the research demonstrated the inherent promise of sweat as a key analytical substrate, especially for the ongoing tracking of glucose levels in those suffering from type 1 and type 2 diabetes.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Alex Tyrer-Jones

Leave A Comment