According to Statista, revenue generated in the Bags & Accessories segment is projected to reach US$96,128m in 2020, and is expected to show an annual growth rate (CAGR 2020-2024) of 9.7%, resulting in a projected market volume of US$139,003m by 2024. Under this circumstance, 3D printed accessories, although not very common yet, has become the new battlefield for fashion designers. Some well-known international brands also join the game. Let’s see what they’ve created.

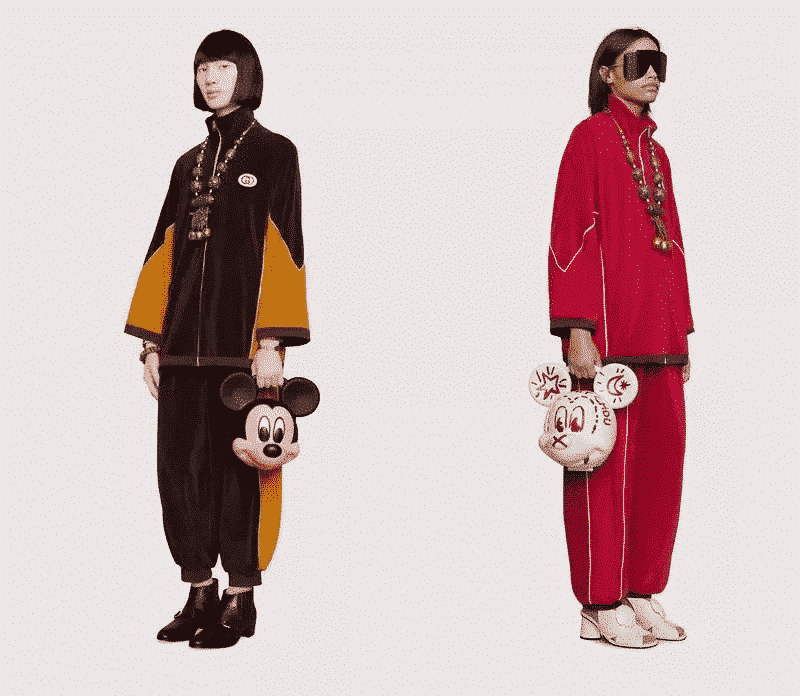

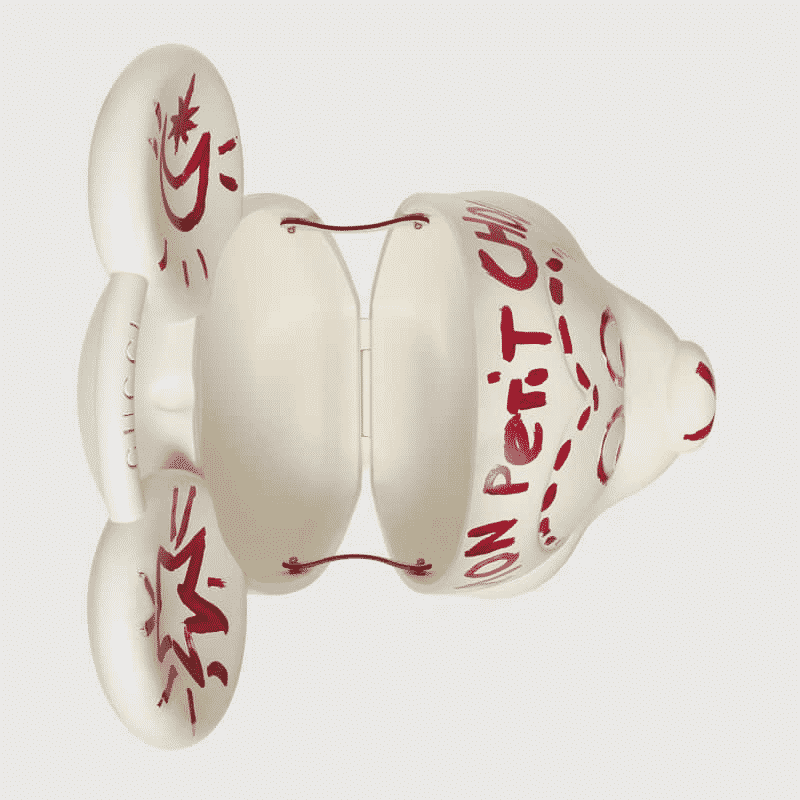

GUCCI

In honor of the 90th birthday of Disney’s Mickey Mouse in 2018, GUCCI published this cheeky adaptation of the famous cartoon character who walked the Spring Summer 2019 runway. Created using a printed 3D technique, the top handle bag is enameled to reflect the character’s most recognizable depiction.

The 3D-printed Mickey Mouse bags were sold for $4,500. 3D-printed from plastic with enamel details, it features a debossed Gucci logo across the handle, and it has a magnetic closure.

EXOCET Design Studio

In August 2014, Exocet was founded by Yasmine Jaber from Beirut, and Morning Lau from Hong Kong. The two designers met in Paris and joined their worlds together to create these hand-bags merged with 3D printed animals.

After several tests and experimenting (laser cutting plastic, assembling leather, etc.), to create these fictitious animals, the designers finally chose to work with 3D printing, which transforms almost everything in your mind into tangible objects.

The name EXOCET, signifying a flying fish is inspired by the metis and unbridled origin of the brand. This is a symbol of Exocet`s hybrid creations; each handbag holds a 3D printed hybrid animal or a vegetable figure.

MALINKO Design Studio

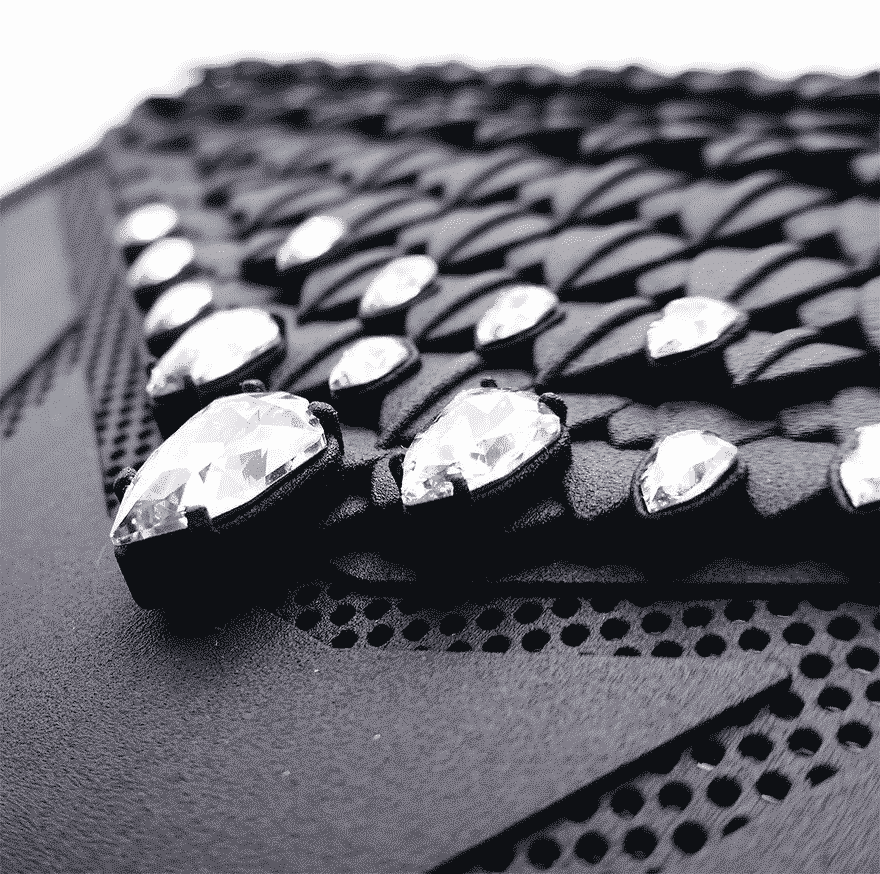

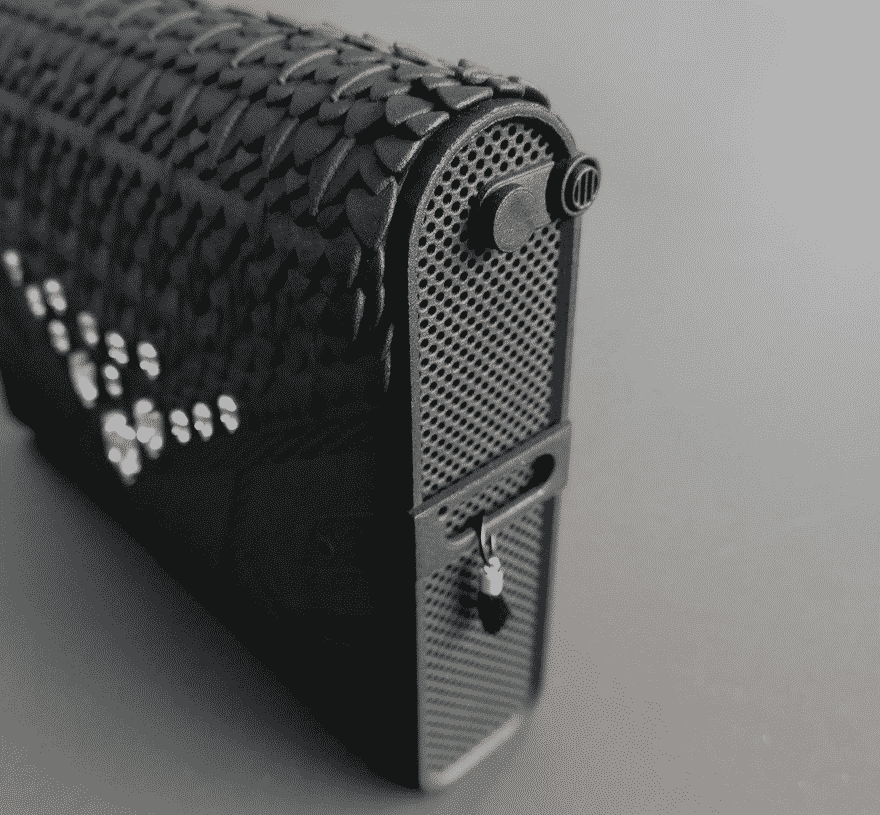

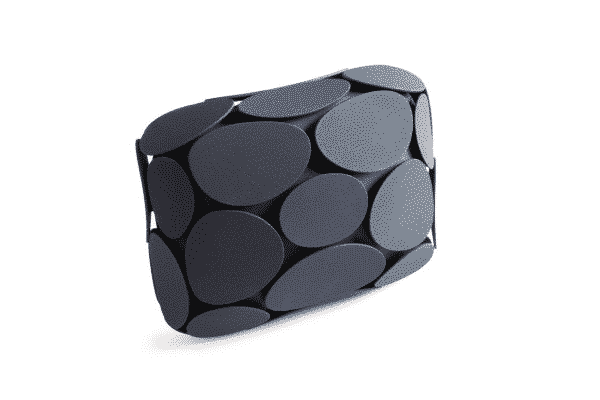

Something we’re surprised that we don’t see more of in the 3D printing space is printed sheets that can be folded into 3D objects. While bed size limitation is certainly a factor, Australia-based industrial designer Mart Cherednik’s Stealth Bag, which is printed in one piece and has embedded hinges and snaps, should give you a good idea of the possibilities:

“It features special Swarovski stone settings that do not require any tools or glue,” Cherednik writes. “The crystals just ‘click in’ to the setting.”

We could see this technique being used for custom-fit electronics cases, tool holsters, knife holders, et cetera.

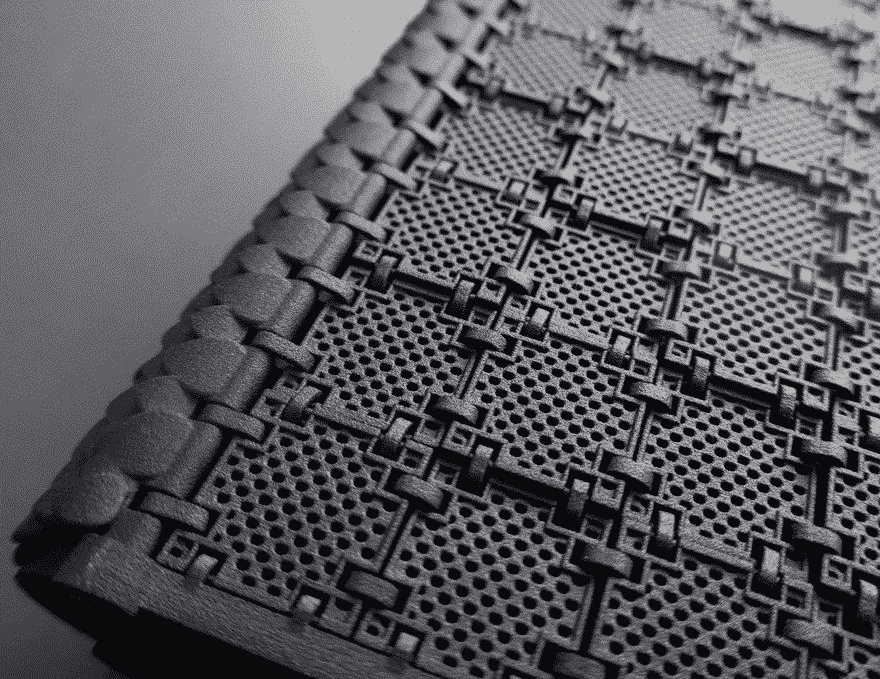

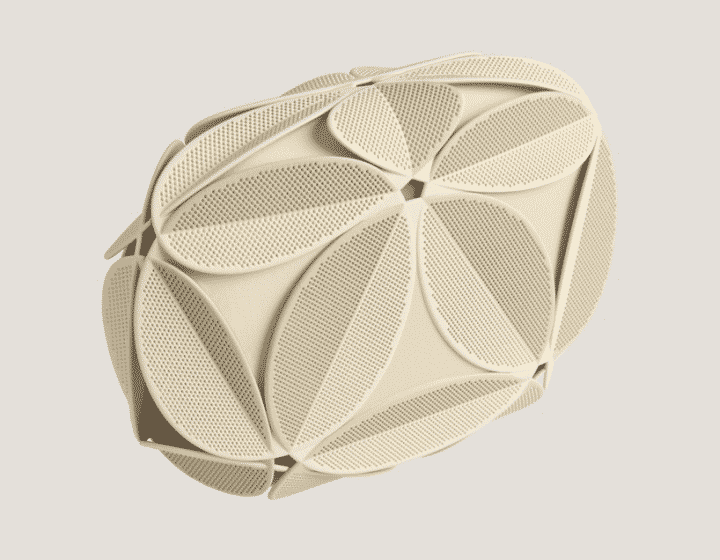

Maison 203

Maison 203, founded by the couple of designers Orlando Fernandez Flores and Lucia De Conti is a brand dedicated to the design, production, and distribution of contemporary jewelry made with 3D printing technology.

Maison 203 accessories are produced in Nylon, PLA (a bioplastic derived from corn starch) steel and brass. Maison 203 is a young company exemplifying the “digital maker” era: 3D printing becomes the “raw material” in the manufacturing of accessories later hand-finished and distributed exclusively to a market niche.

The catalog displays collections very different from one another, because designed in collaboration with professional designers coming from various cultural backgrounds. They have launched a series of clutch bags: ARMURE, IVY, and BERN.

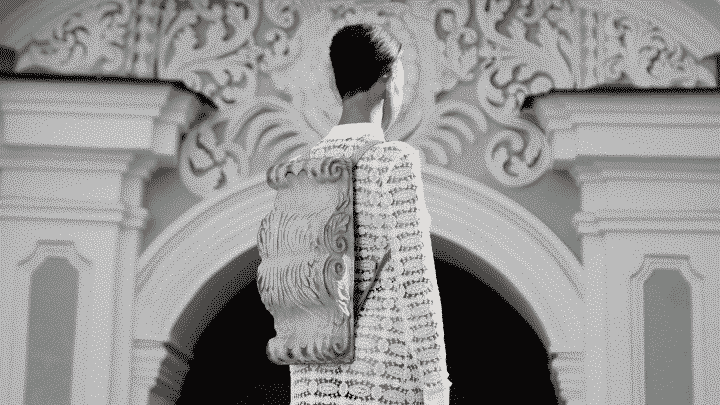

Konstantin Kofta Studio

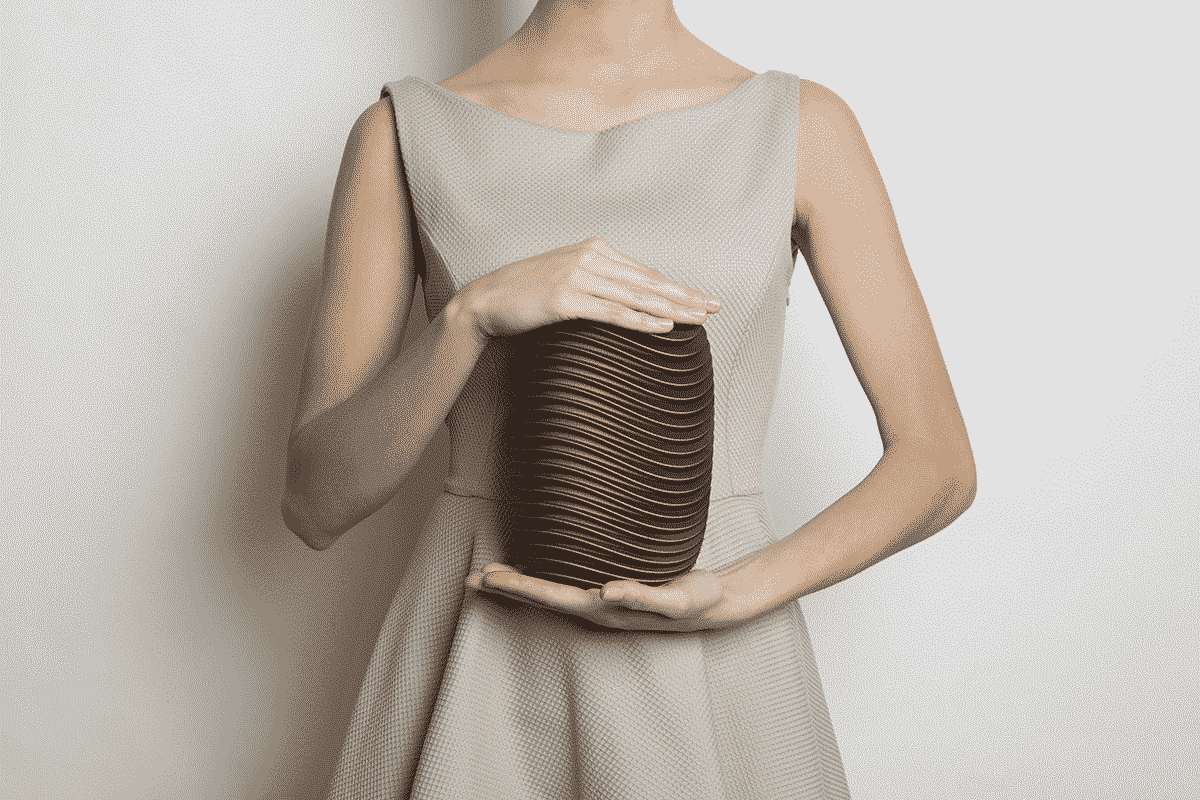

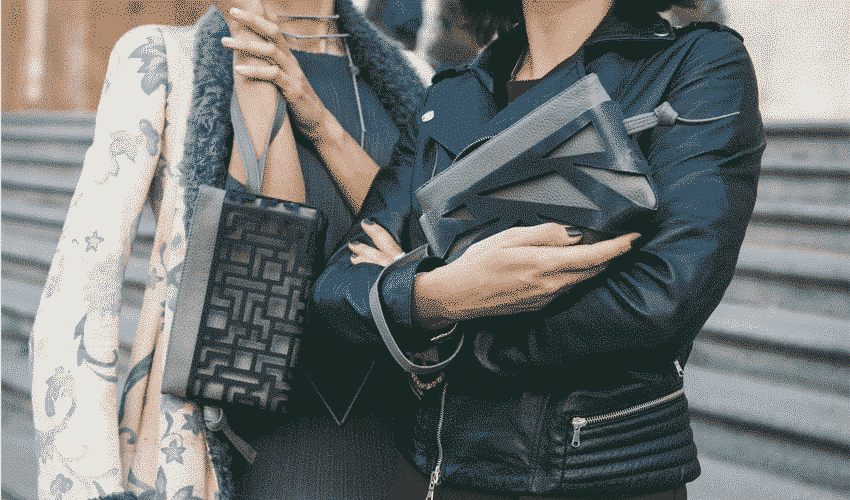

Known for his daring and unconventional leather-accessory design, Ukrainian fashion designer Konstantin Kofta has just released his latest collection of leather bags and clutches. Kofta likes to draw inspiration from natural shapes, like seashells and parts of human anatomy, which he then transforms into fully-functional garments and accessories. Bearing the title “ARXI”, Kofta’s SS16 collection takes the designer’s approach a step further, by incorporating and inspired by forms and imagery found in Baroque architecture.

XYZBAG

XYZBAG is an Italian brand based in Turin that has chosen digital craftsmanship: it combines traditional design methods and additive manufacturing technologies to produce unique bags.

“Each project we encounter is unique. That’s why we start with a special dialogue with our customers. Our 3D bags are a system product. We combine Italian traditional craftsmanship and innovative 3D technologies. Any 3D printed cover begins with a digital solid model, created through computer-aided design (CAD) software. Our clients can select among different cloud design suggestions (skyline, logo, text, different style), based on 3 master products (DADA, GRETEL, TRADA) or simply ask us to generate one specifically for them. This is the most delicate stage. The art of digital personalization requires huge expertise in creating a file suited for 3D printing, and the ability to produce anything that can be imagined by the customer, rather than limiting designs to production constraints.” said Annalisa Nicola, the co-founder of XYZBAG.