3D LifePrints, a leading 3D technology company providing innovative solutions to the medical sector, has achieved ISO 13485:2016 certification for its Quality Management System (QMS).

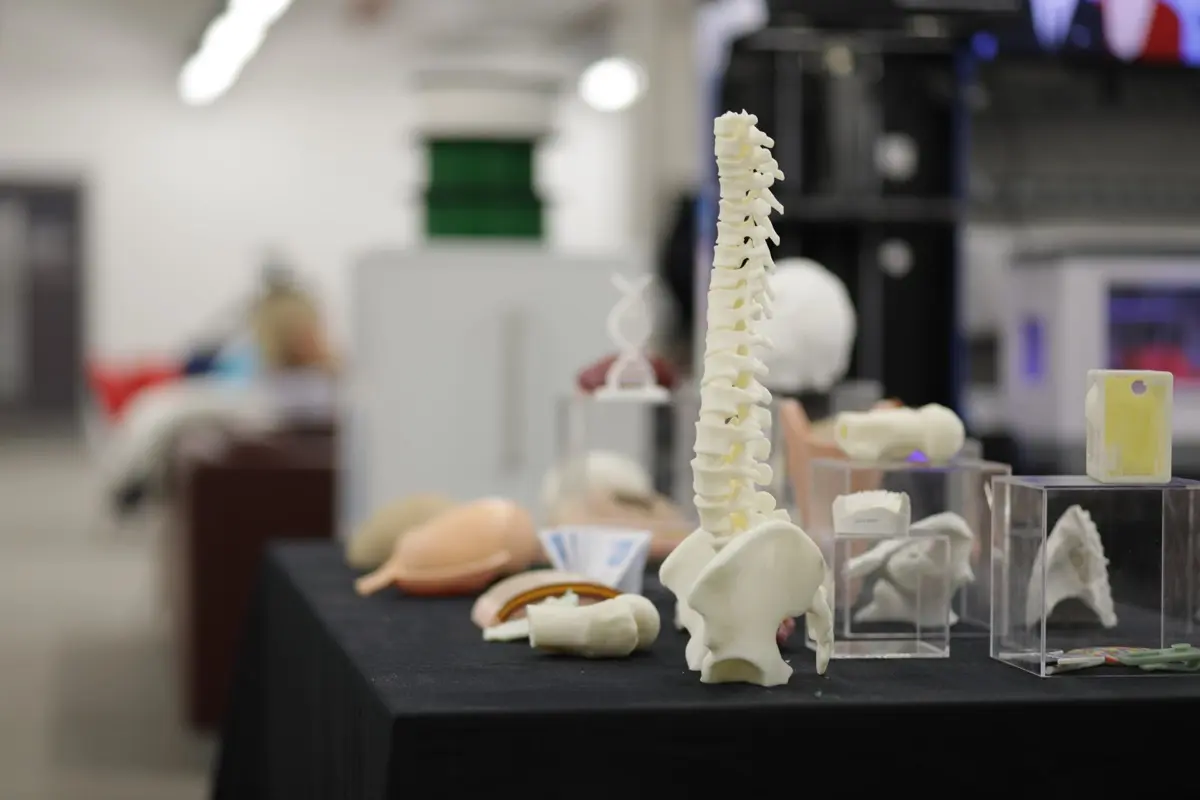

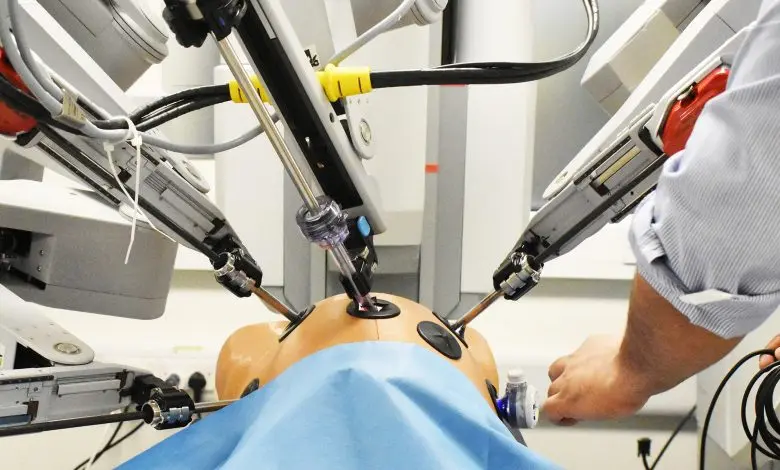

The certification enables 3D LifePrints to expand its industry-leading point-of-care model by launching a new range of patient-specific sterilizable surgical guides and anatomical models, whilst continuing to deliver its existing custom-made medical devices.

The certification is underpinned by 3D LifePrints’ Digital Platform Embedmed. It includes the design and manufacture of sterilizable devices within a Controlled Environment in one of 3D LifePrints’ embedded Hubs. This innovation brings the timeline for delivery of these types of devices down from weeks to days.

Manufacturing on Demand

“It has long been our goal to standardize our processes by adherence to this internationally recognized standard,” commented Henry Pinchbeck, CEO 3D LifePrints: “The formal certification of our QMS opens up considerable market opportunities for the business and is a clear signal to our customers of the importance we attach to Quality Assurance and Patient Care.”

An internationally recognized standard of excellence, ISO 13485:2016 is a stringent set of guidelines for the medical device industry. The standard ensures that an organization maintains its quality and compliance levels specific to the design, manufacture and distribution of medical devices.

3D LifePrints’ primary focus is the supply of patient-specific 3D printed medical devices to organizations including hospitals, universities, and medical device manufacturers. Their current key Hubs include Alder Hey Children’s Hospital in Liverpool, Nuffield Orthopaedic Centre in Oxford, Wrightington Hospital in Greater Manchester and Leeds General Infirmary.

The company operates a unique operating model where the products are delivered As A Service from embedded Hubs within host institutions. The Point-of-Care service includes bio-medical engineers; a range of advanced 3D printing hardware and a suite of software. The embedded nature enables the host institution to enjoy all of the benefits of having an ‘in-house’ service including ease of access to an engineer and immediate delivery of the devices.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment