3D Bioprinting Solutions, a Russian bio-technical research laboratory, has 3D bioprinted bone tissue in zero gravity on the International Space Station (ISS).

Executed on the lab’s magnetic 3D bioprinter Organ.Aut, this experimentation is working to enable the creation of bone implants for astronaut transplantation during long-term interplanetary expeditions.

Zero gravity 3D bioprinting

As a subsidiary of Invitro, a private medical company in Russia, the Moscow-based 3D Bioprinting Solutions created the Organ.Aut to study how living organisms are affected by long flights in outer space. Last year, it was delivered to the ISS onboard the Soyuz MS-11 manned spacecraft following a previous failed launch from the Soyuz MS-10 spaceflight.

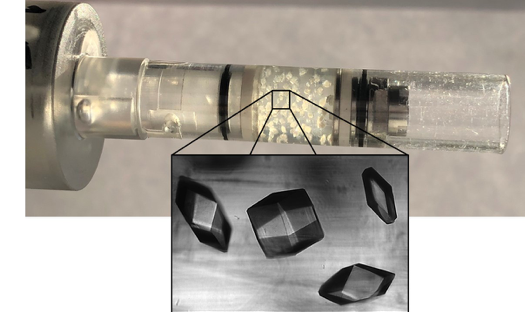

Earlier this year, the company announced plans to collaborate with scientists from the U.S. and Israel to deliver muscular tissue biomaterials. Following this, its researchers carried out a high molecular weight protein crystallization experiment in zero gravity using a new method dubbed as magnetic sedimentation of protein molecules. Such tests resulted in crystals measuring from 300 to 1500 micrometers.

According to the team, this study could lead to unique protein crystals exclusively produced in space. Ultimately this could aid in the creation of advanced drugs that affect viruses and bacteria at the molecular level.

Manufacturing on Demand

Advancing medical care for astronauts

Described by 3D Bioprinting Solutions as a first, 3D bioprinted bone tissue was fabricated in space using growing fragments of bone structures. The tissues comprised of calcium phosphate ceramics populated with living cells. This aims to aid ailing astronauts who may experience a decline in health due to bone structure degeneration from extensive exposure to microgravity.

Currently, the researchers have identified a lack of specialized medical care for such maladies. The latest samples are now being studied on Earth to determine their viability for transplantation in the future.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Tia Vialva

Leave A Comment