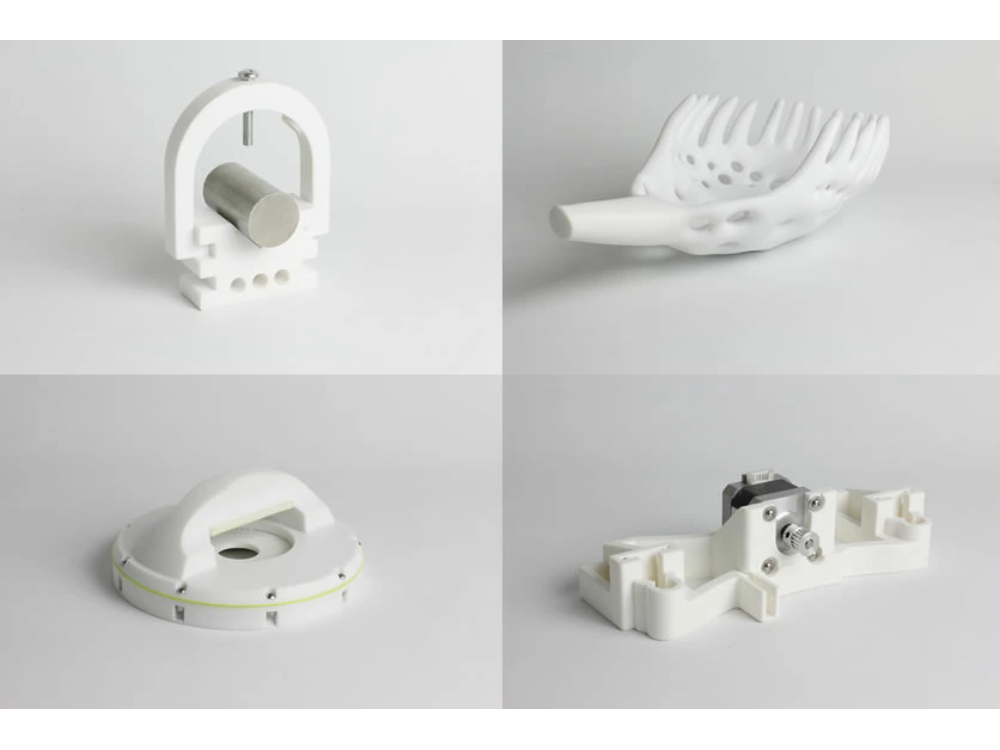

FDM PolyLite ABSPolymaker PolyLite ABS PolyLiteŌäó ABS is made with a specialty bulk-polymerized ABS resin, which has significantly lower volatile content compared to traditional ABS resins. It delivers excellent printing quality with minimal odor during printing. Max Build Size Min Build Size 8 x 8 x 8 mm Default Layer Height 0.18 mm Optional Layer Heights 0.1, 0.2 mm Tolerance ┬▒0.2% (with a lower limit of ┬▒0.2 mm) Up to 98.2 Ōäā Smooth ŌśģŌśģŌśģ Detail ŌśģŌśģŌśģ Accuracy ŌśģŌśģŌśģ Rigidity ŌśģŌśģŌśģ Flexibility ŌśģŌśģŌśģŌśģ Available ColorsBlack

Available Post ProcessSuitable For Functional prototypes and end products, Not Suitable For Complex designs with intricate details, Additional InfoPolyLiteŌäó is a family of 3D printing filaments made with the best raw materials to deliver exceptional quality and reliability. PolyLiteŌäó covers the most popular 3D printing materials to meet your everyday needs in design and prototyping. PolyLiteŌäó ABS is made with a specialty bulk-polymerized ABS resin, which has significantly lower volatile content compared to traditional ABS resins. It delivers excellent printing quality with minimal odor during printing.

Feature

3D PrinterMaterial Spec Sheet

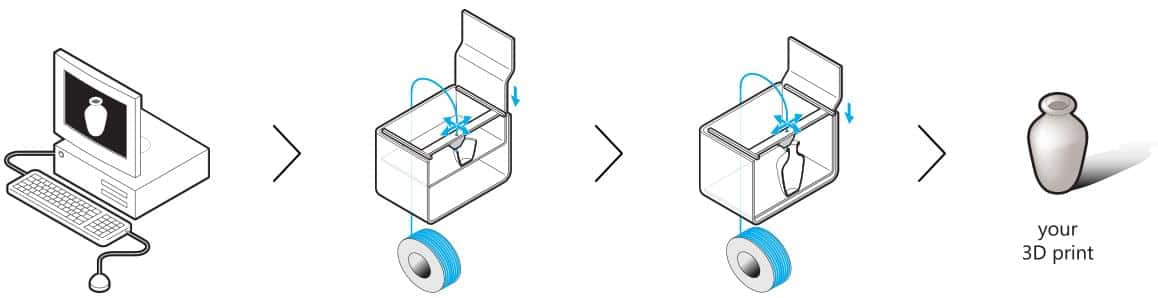

Fused Deposition Modeling is used to build your design with this material. The principle is simple. You can compare it with a hot glue gun into which you put sticks of glue. The glue is heated up until it melts and is then pushed through a fine nozzle in the front of the glue gun. In an FDM printer, a long plastic wire is used in place of glue. It is fed from a spool to the nozzle where the material is liquefied and ŌĆśdrawnŌĆÖ on the platform where it immediately hardens again. The nozzle moves to drop the material at the correct location, drawing your model line by line. When a layer is drawn, the platform lowers by one layer thickness so the printer can start with the next layer. When your model contains overhanging sections, the printer needs to build supporting material. Since the material of the model cannot be deposited in the air, the support material prevents it from falling down. This support material is fed through another nozzle. Afterward, when the model is put into a bath with special soap, the support material dissolves.

|