Die Casting Services

3-axis milling and 5-axis indexed milling processes with more than 30 engineering-grade plastics and metals as fast as 48 hrs.

Overview: How Die Casting works?

The Basics Of Die Casting

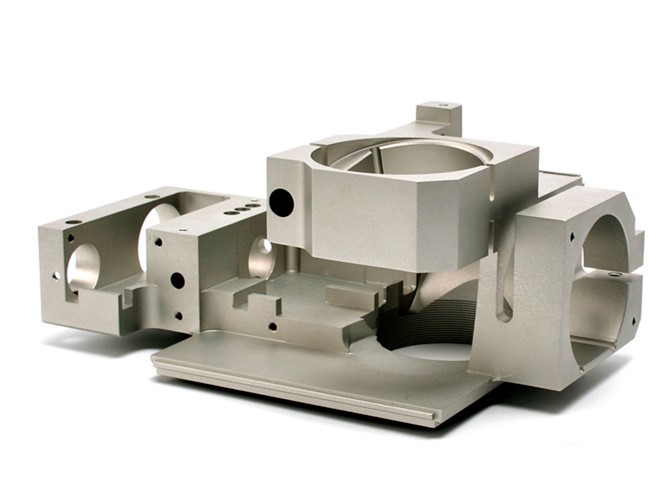

CNC machining is a subtractive manufacturing process where raw material is removed with a variety of precision cutting tools to make a part or product.

Programmed software is used to control the equipment according to the specification of your 3D design.

CNC Milling in Progress

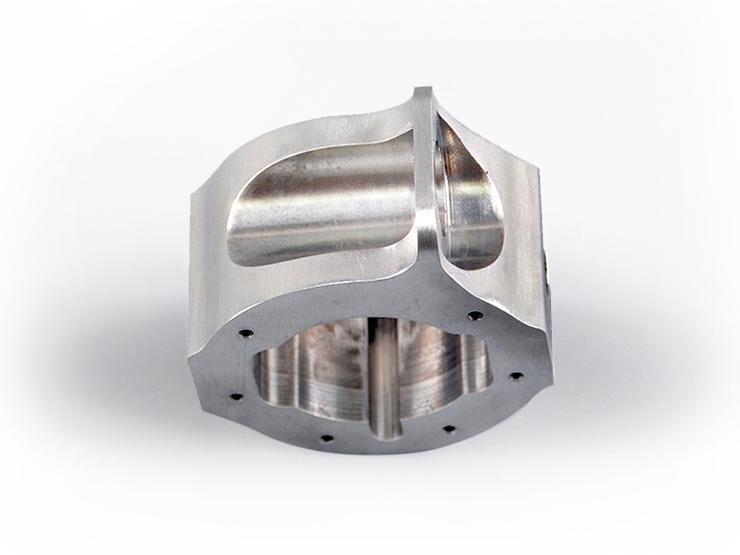

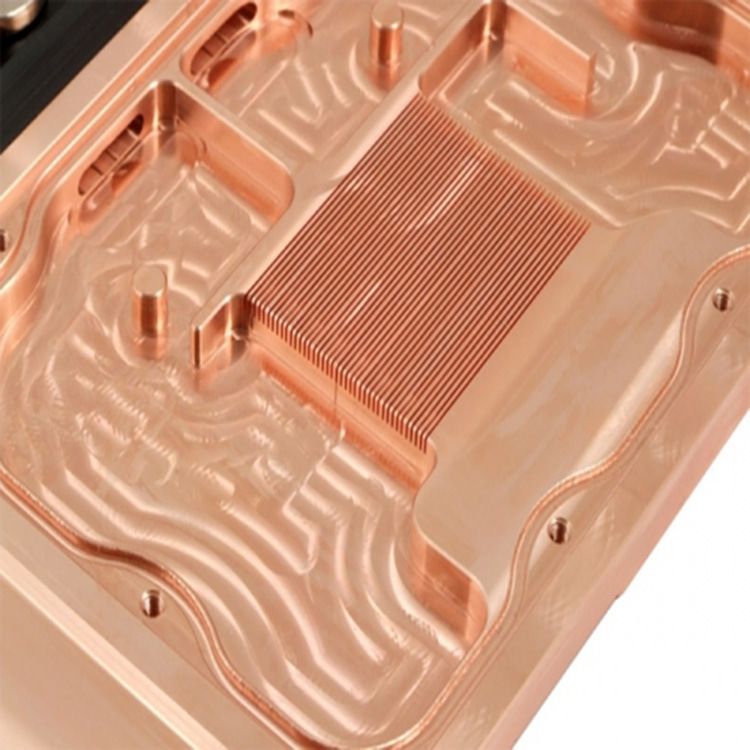

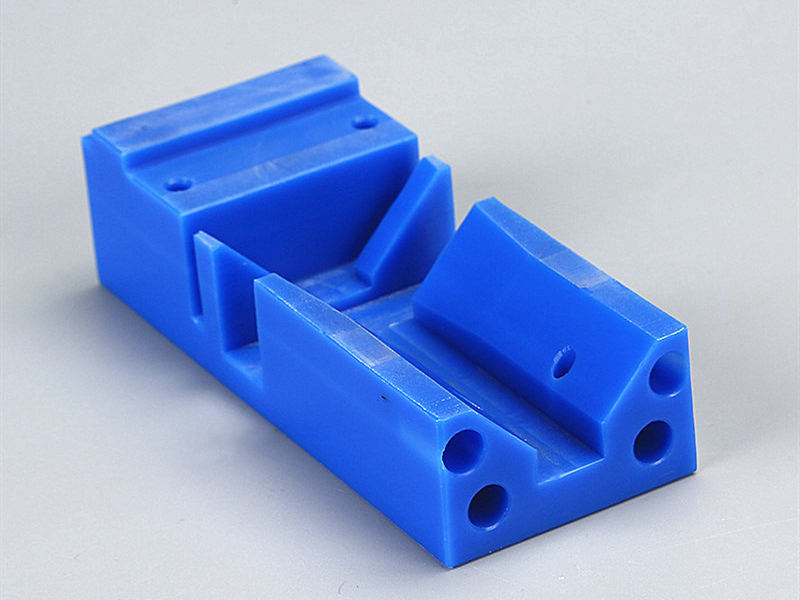

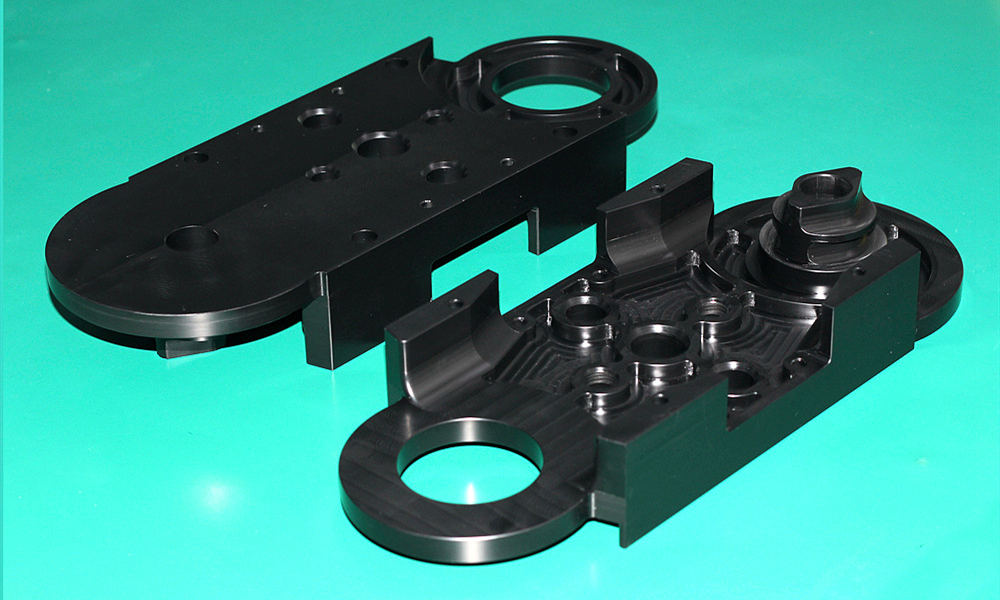

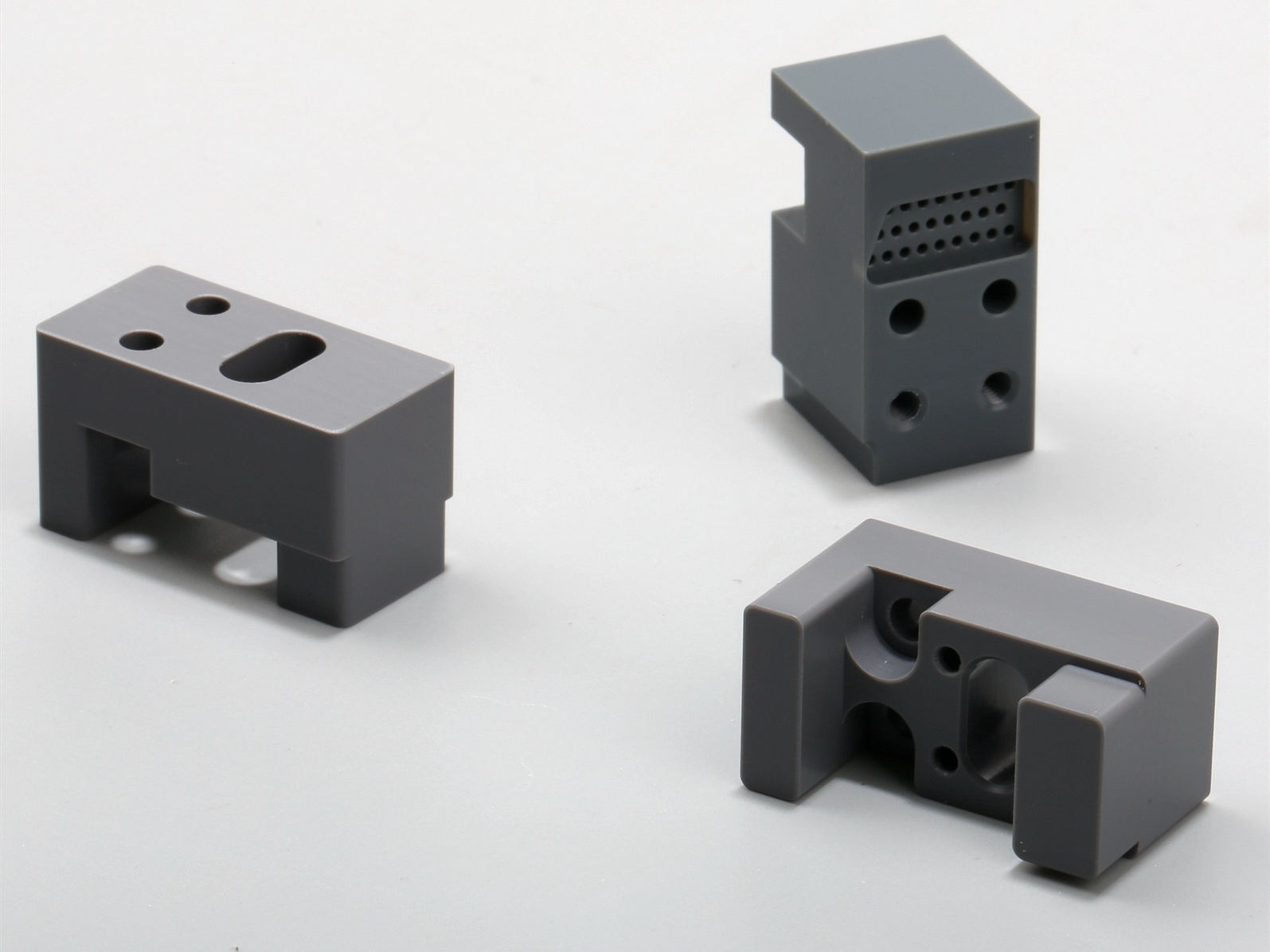

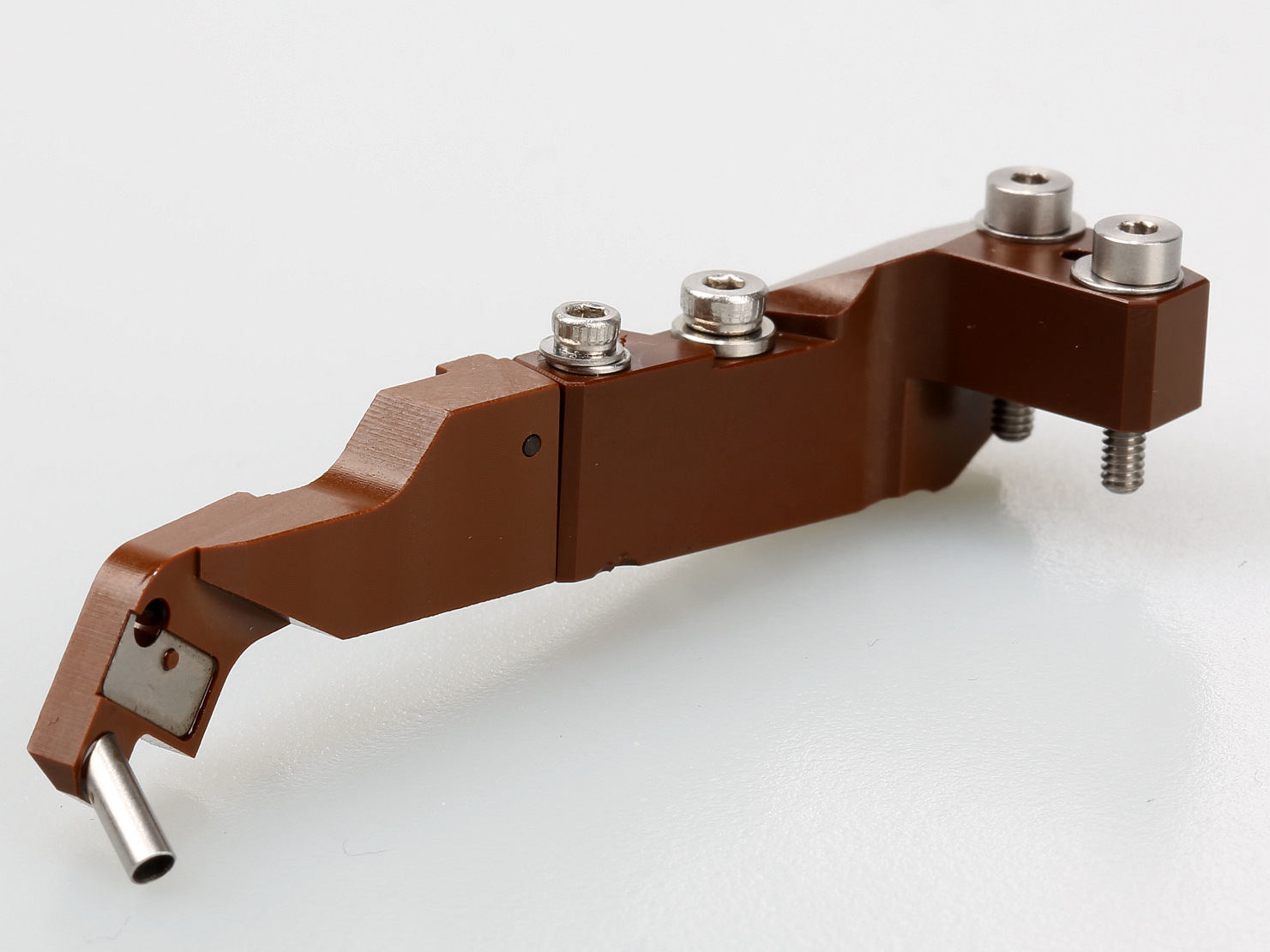

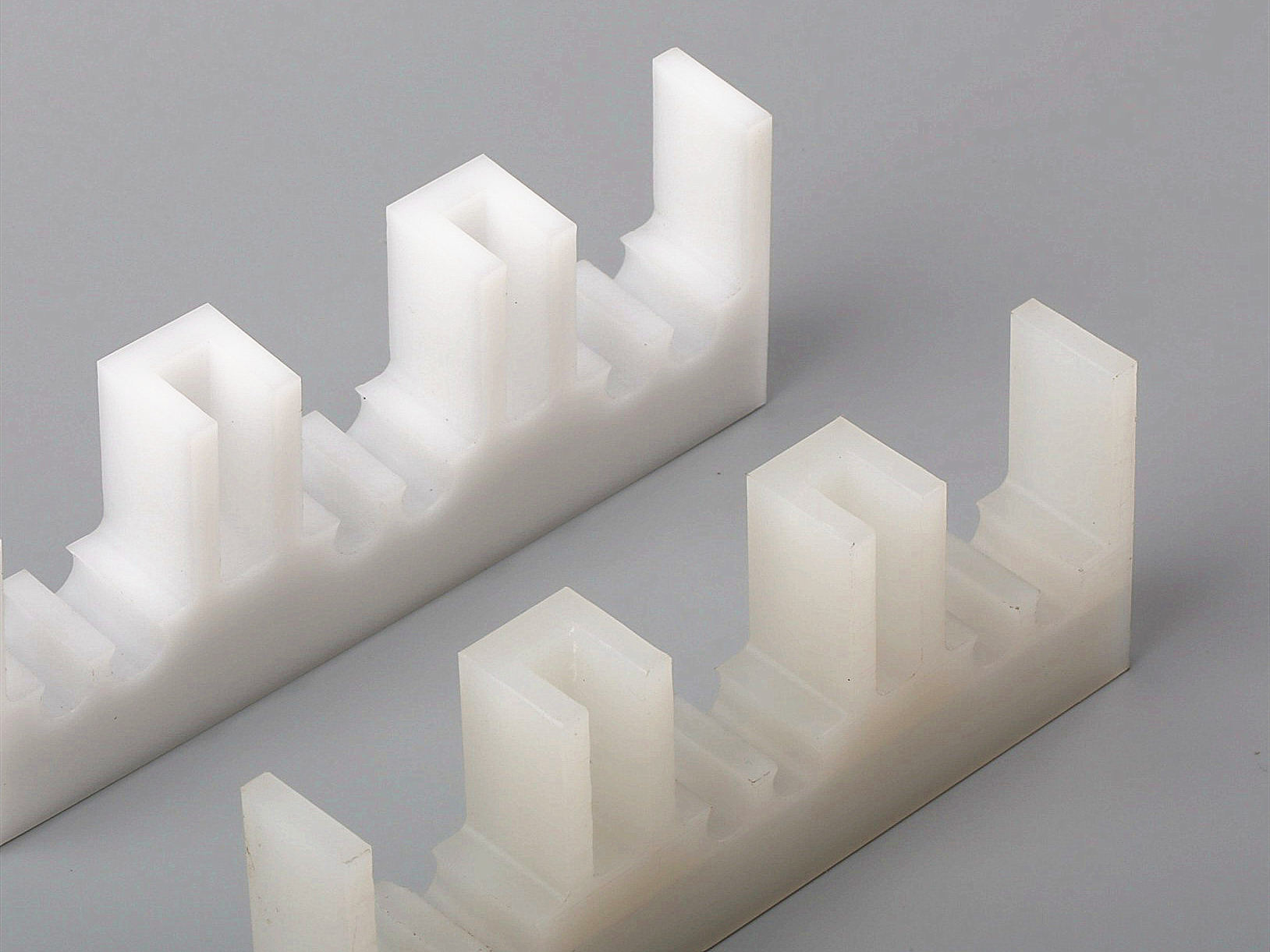

We use Die Casting not only to manufacture parts and prototypes but also to make mold tools, which can be used for our plastic injection molding or presure die casting services.

How Die Casting Works

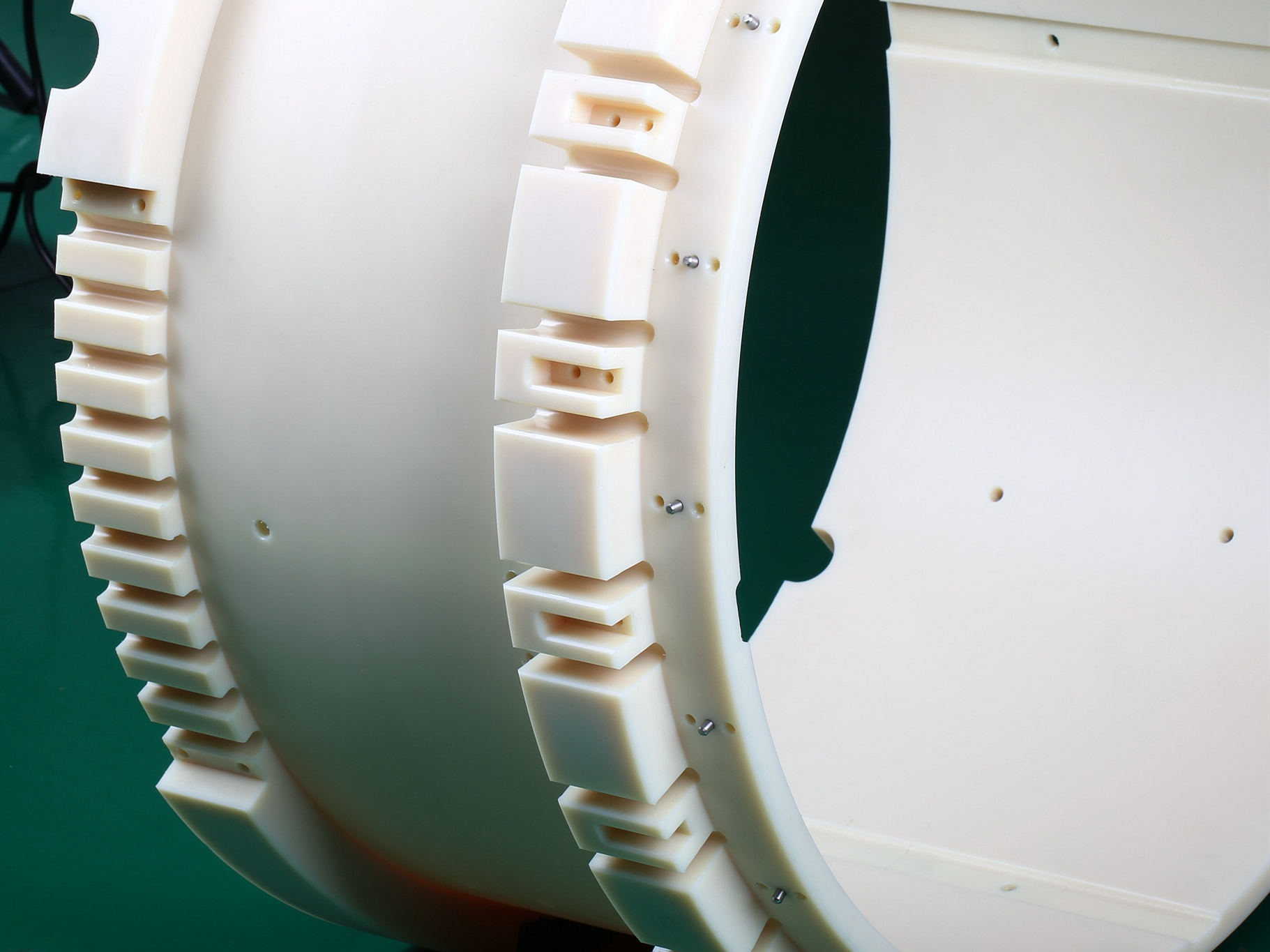

With a 3-axis machine, the rotating tool mentioned above can translate relative to the part in the X, Y, and Z axes (thus the name), but is fixed in a vertical (or horizontal, depending on the machine) orientation. With modern CNC mills, the tool can also move in any combination of the 3 axes simultaneously.

A 5-axis machine is capable of the same movements as a 3-axis machine, but with added rotation about the X and Y axes. It is usually the bed that rotates rather than the toolhead, though both types of machines do exist. This added rotation allows for much more freedom when machining each setup.

Types Of Die Casting

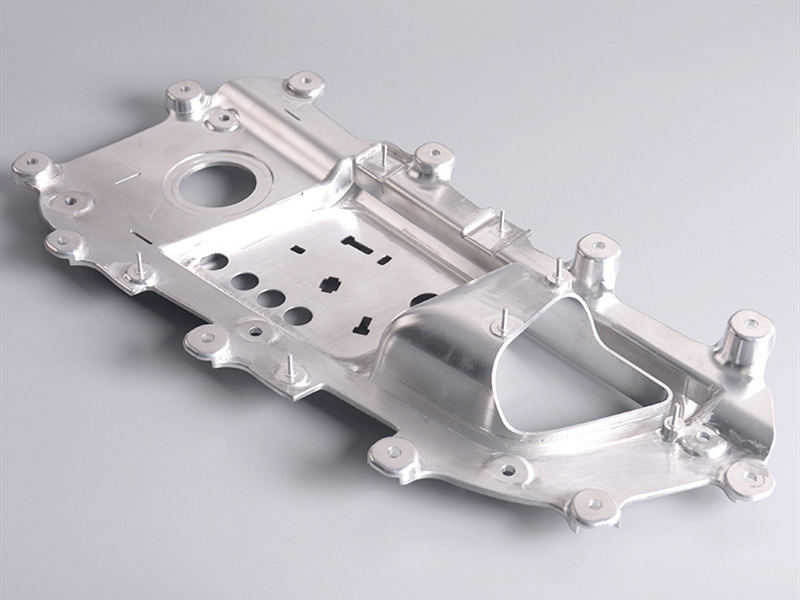

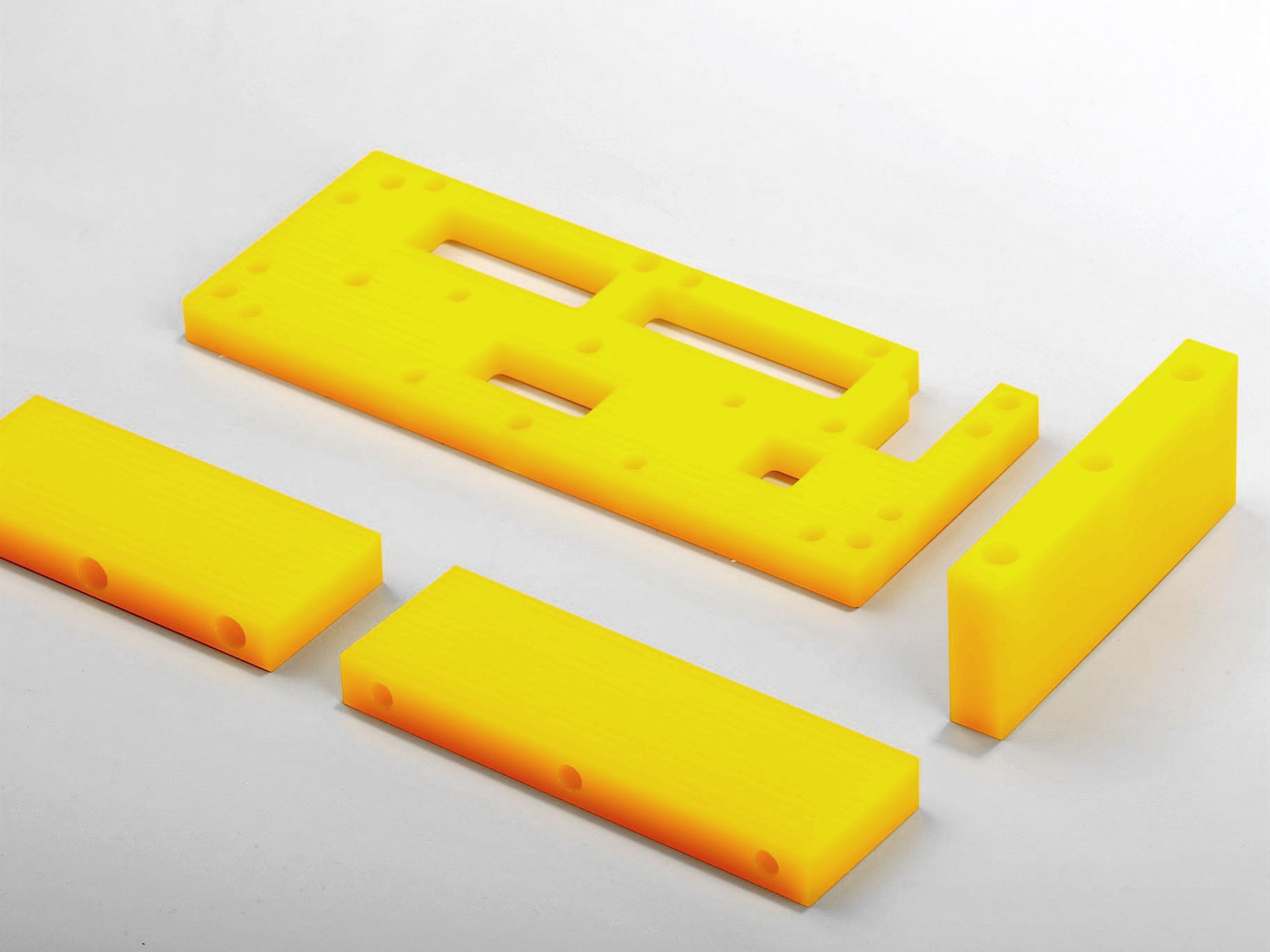

At FacFox, we offer you a variety of Die Casting services including milling, turning, EDM, wire EDM, surface grinding and much more. Using our imported 3, 4 and 5-axis Die Casting centers, our skilled machinists can make turned and milled parts using a wide range of plastic and metal materials. Our Die Casting abilities also complement our 3D metal printing service making us a great one-stop service for your advanced designs.

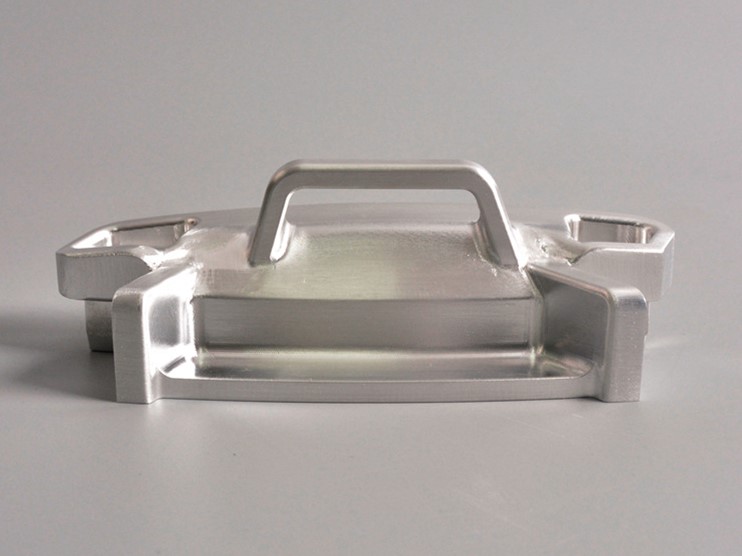

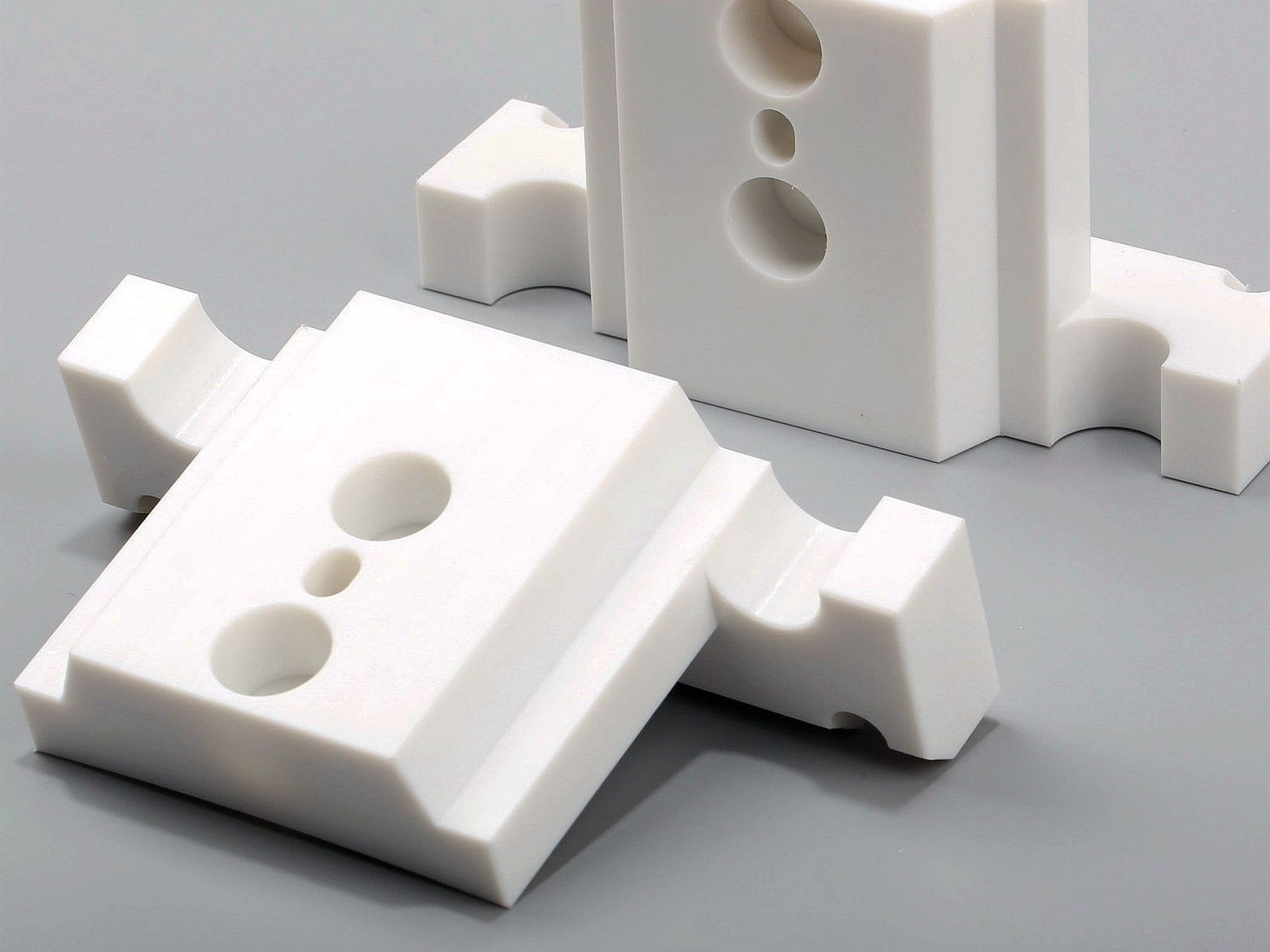

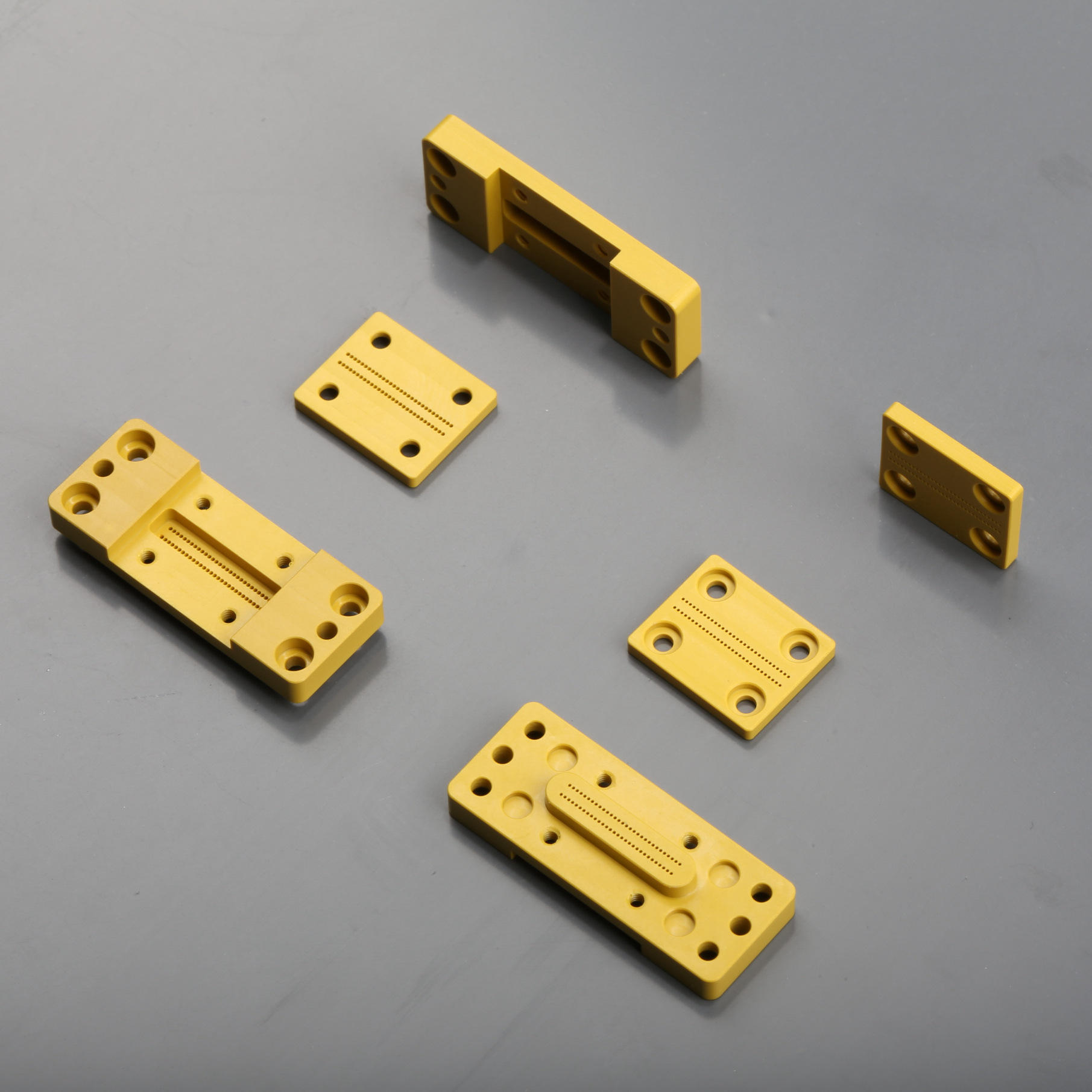

Machined plastic parts are left as-milled, which typically means they show visible tool marks. Some metal parts allow more finishing choices. When the run is complete and your required surface finish is applied, parts are boxed and shipped shortly thereafter.

Features of CNC

Advantages

Drawbacks

CNC Processes

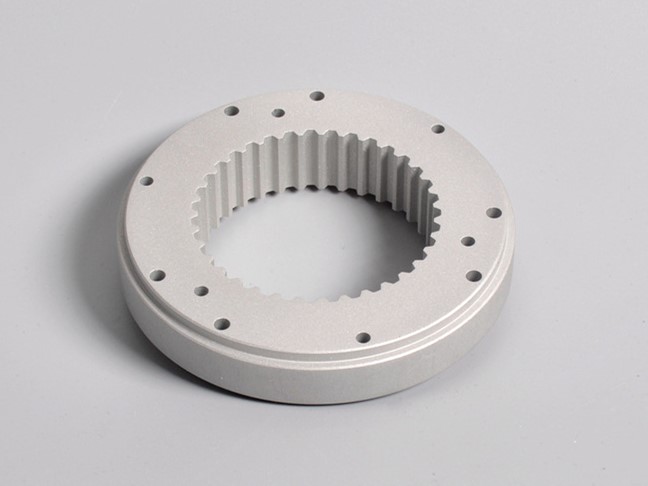

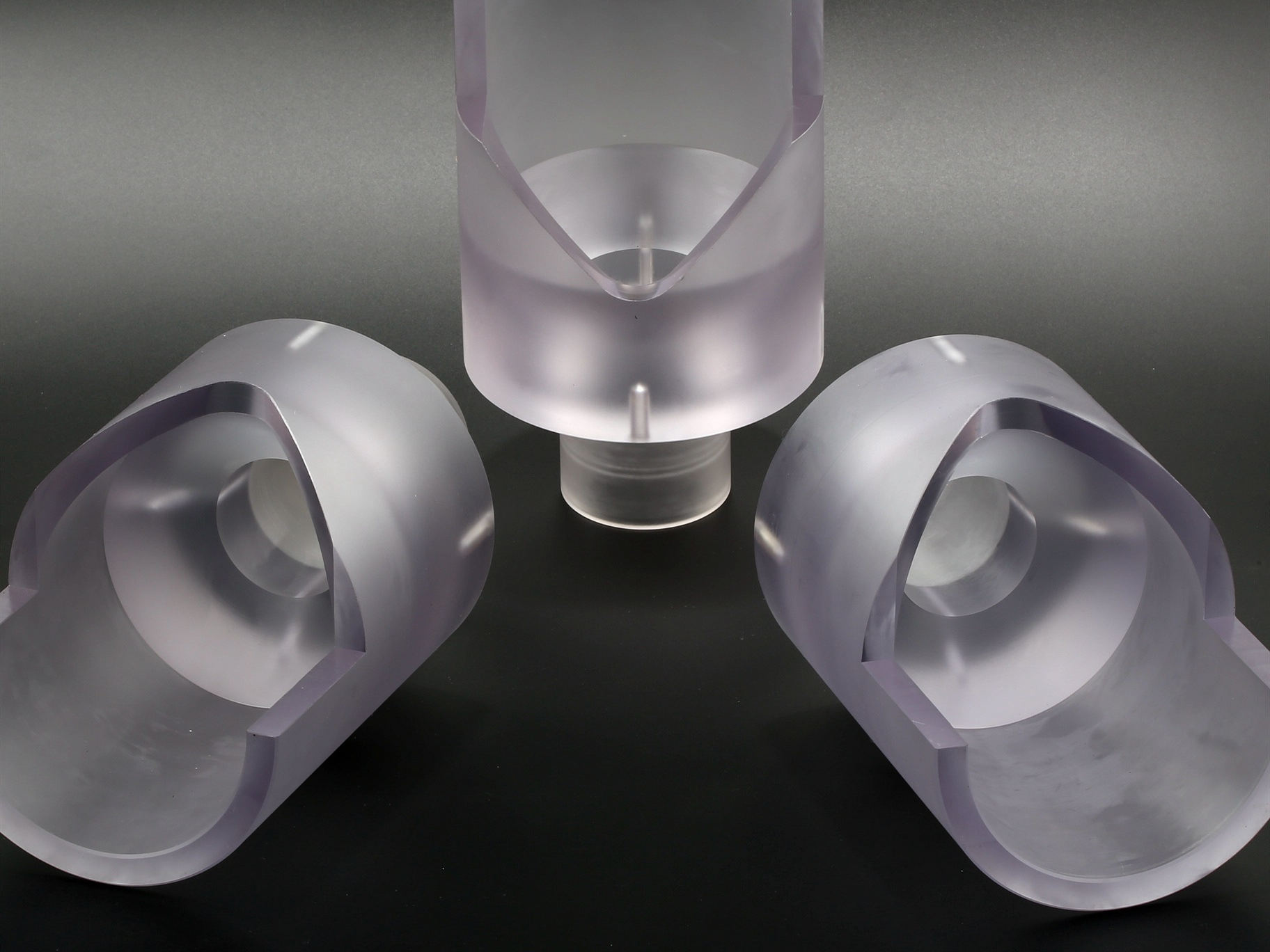

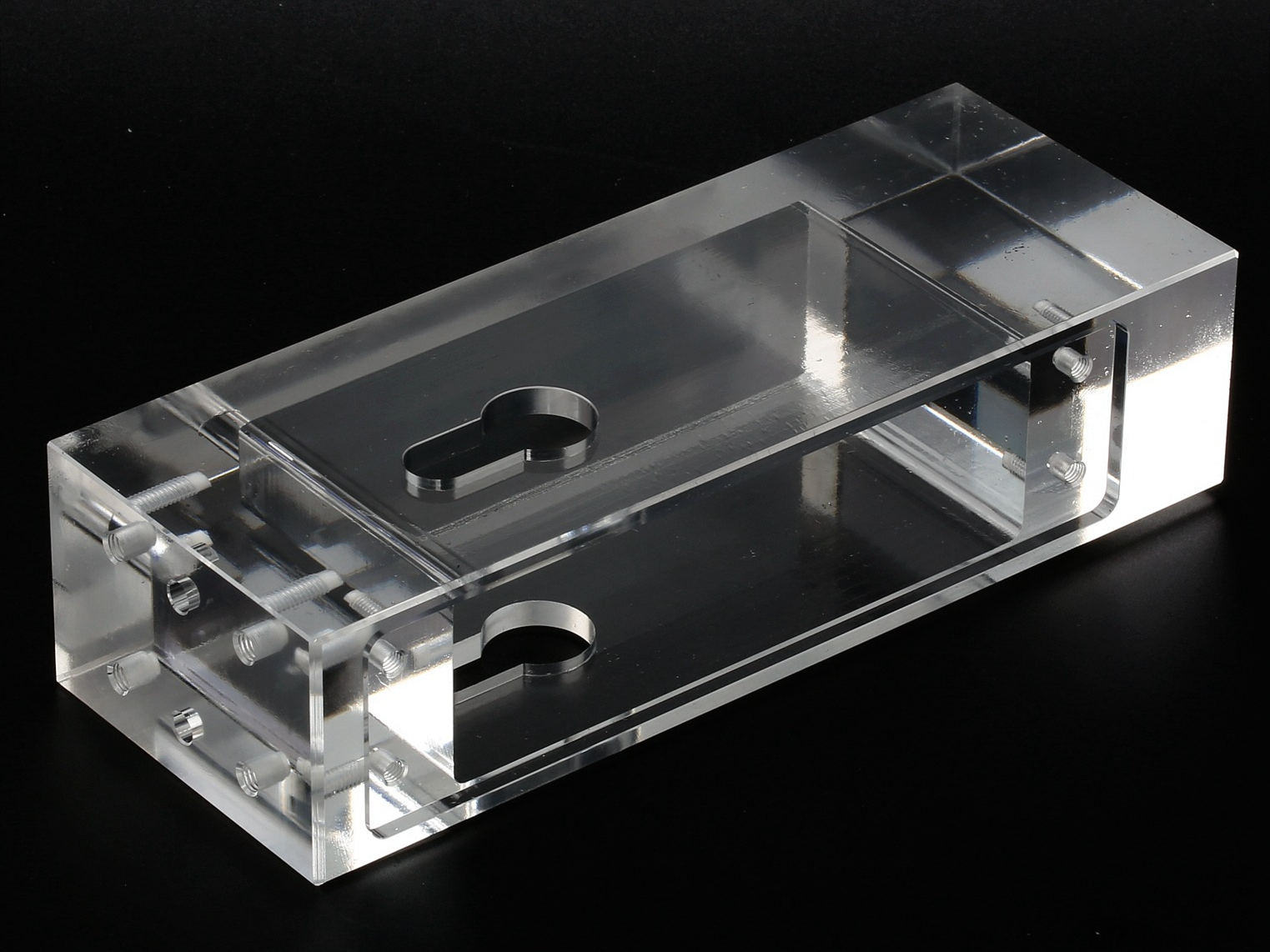

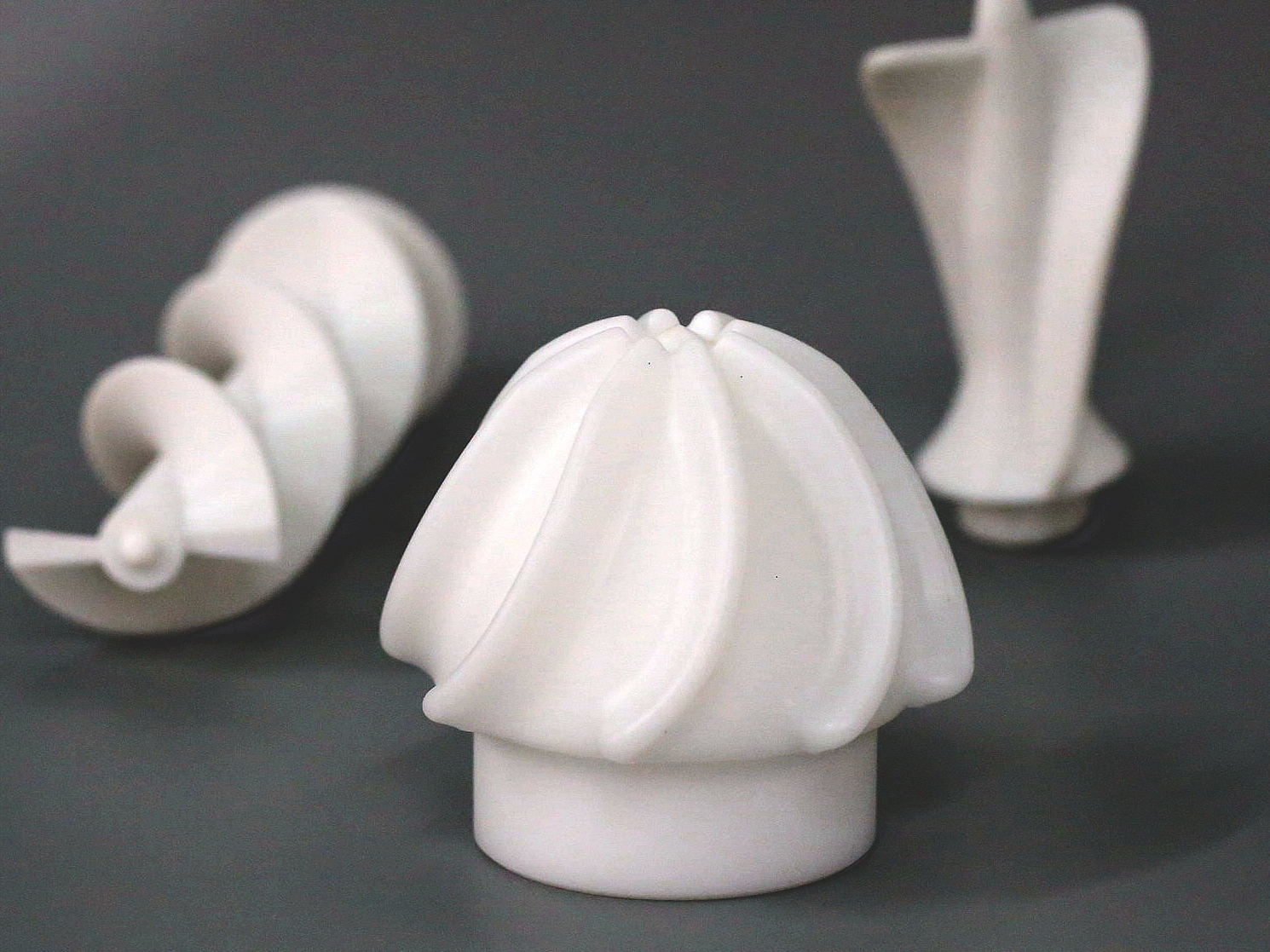

CNC milling is used to apply a machined surface finish on plastic or metal, or for creating complex 3D shapes. We use domestic and imported 3, 4 and 5-axis Die Casting centers with quick-change tooling, and advanced programming software. CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to low-volume production. EDM (electrical discharge machining) is a method for cutting holes, pockets and other shapes into hardened steel, as well as imparting a surface texture to the internal cavities of mold tools. It’s able to cut through hardened tool steels quickly and accurately.CNC Milling

CNC Turning

EDM / Wire EDM

Available Materials

Available Finishes

The finish option with the quickest turnaround.

Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

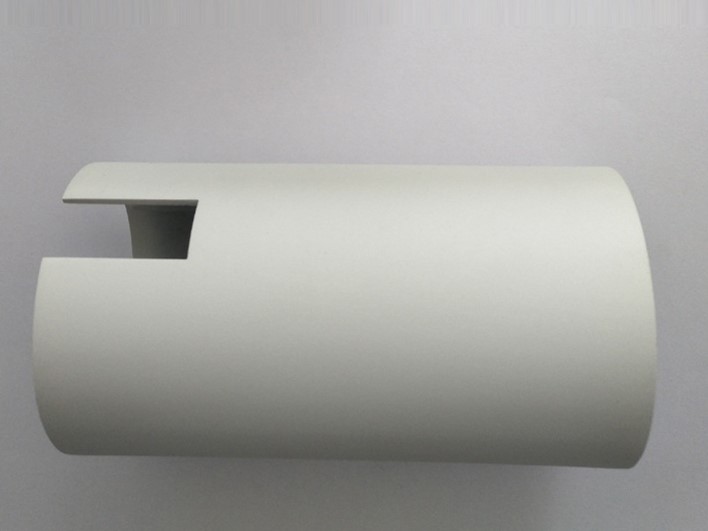

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in coating and is then cured under heat to allow it to flow and form a “skin”. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware and automobile and bicycle parts.

- Electroplating

- Spray-Plating

- Don‚Äôt see the finish you need? Submit an RFQ with ‘Suggest’ option, we‚Äôll look into a finishing process for you.

CNC Applications

With Die Casting, the prototype can be made using the exact material that will eventually be produced before the mass production. High tolerance makes it a good choice for functional prototyping. CNC can be applied to make high- quality tools from aluminum 7075-T6 for injection molding, while steel tooling made from P20, NAK80 and H13 is available for volumes up to 100,000 pieces. With Die Casting, the low volume end products can be made using the exact material that will eventually be produced before the mass production, some simple parts can even be mass produced.Prototypes

Mold Making

End Products