(MIM) Metal Injection Molding Services

Sheet metal prototypes and low-volume production parts shipped in as fast as 2 days

Overview: How Metal Injection Molding Service (MIM) works?

The Basics Of Metal Injection Molding (MIM)

Metal Injection Molding (MIM) is an effective way to produce complex and precision-shaped parts from a variety of materials. This process produces parts for 50% less than the cost of CNC machining or casting. MIM is able to produce parts with complex shapes, superior strength and excellent surface finish with high volume manufacturing.

Benefits of Metal Injection Molding Services With FacFox

MIM offers greater design freedom than many other production processes by freeing designers from the traditional constraints associated with trying to shape stainless steel, copper, titanium, and other metals. Other benefits of MIM, include:

- MIM makes it possible to integrate and consolidate several components into a single molded pieceŌĆöreducing the need to work with several manufacturers and decreasing processing and assembly costs.

- Texture, knurling, threads, lettering, and company logos can all be incorporated into the mold.

- At FacFox, we also provide fast prototyping service for metal products with DMLS metal 3D Printing, validate your design before investing big in molds!

Features of Metal Injection Molding (MIM)

Advantages

Drawbacks

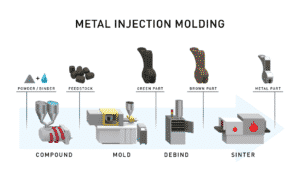

Metal Injection Molding (MIM) Processes

A special polymer and metal blended feedstock is injection molded and we get a so called “green part”. The “green part” is then put through a controlled process called debinding that removes the binder. Once the debinding is complete, the component is referred to as “brown”. During sintering temperatures reach near the melting point of the material. Sintering eliminates the remaining binder and gives the part its final density and strength.Compound & Molding

Debinding

Sintering

Available Materials

| Chemistry | Grade | Density | Size | Hardness | Application Data | |

| PIM / MIM Powder | ||||||

| HR304(L) Stainless Steel Powder Atomized |

Cr:18-20 Ni:8-12 C:0.08(0.03) Si:1max Mn:2max Fe:bal. |

304(L) | app.4.1-4.5 tap.>4.9 g/cm3 |

150um 75um 45um 15um |

34.5HRC | MIM part weight:0.03-200g Apparent relative density>95% Sinter density>7.6g/cm3 sinter temperature:1360-1380c Shrinkage rate:1.18 |

| HR316(L) Stainless steel powder Atomized |

Cr:16-18 Ni:10-14 Mo:2-3 C:0.08(0.03) Si:1max Mn:2max Fe:bal. |

316(L) | app.4.1-4.5 tap.>4.8 g/cm3 |

150um 75um 45um 15um |

36HRC | MIM part weight:0.03-200g Apparent relative density>95% Sinter density>7.8g/cm3 sinter temperature:1360-1380c Shrinkage rate:1.18 |

| HR174PH Stainless steel powder Atomized |

Cr:15.5-17.5 Ni:3-5 Nb:0.15-0.45 Cu:3-5 C:0.07 Si:1max Mn:1max Fe:bal. |

17-4PH | app.4.1-4.5 tap.>4.8 g/cm3 |

150um 75um 45um 15um |

35HRC | MIM part weight:0.03-200g Apparent relative density>95% Sinter density>7.8g/cm3 sinter temperature:1360-1380c Shrinkage rate:1.18 |

| HR420 Stainless steel powder Atomized |

Cr:12-14 C:0.25max Si:1max Mn:1max Fe:bal. |

420 | app.4.1-4.5 tap.>4.8 g/cm3 |

150um 75um 45um 15um |

HRC50 | MIM part weight:0.03-200g Apparent relative density>95% Sinter density>7.8g/cm3 sinter temperature:1360-1380c Shrinkage rate:1.18 |

| HR430 Stainless steel powder Atomized |

Cr:16-18 C:0.12max Si:1max Mn:1max Fe:bal. |

430 | app.4.1-4.5 top.>4.8 g/cm3 |

150um 75um 45um 15um |

HRC51 | MIM part weight:0.03-200g Apparent relative density>95% Sinter density>7.8g/cm3 sinter temperature:1360-1380c Shrinkage rate:1.18 |

| HR70Cr | Cr:65-70 C:0.06(0.03) Si:1.0max S:0.03max P:0.03max |

70Cr | / | -75um -45um |

/ | As additive for special part require anti-wear and anti-corrosion, like auto valve shaft guide pipe, seat etc. |

| HR60Mo | Mo:60-65 C:0.04max S:0.15max P:0.06max Si:1.5max |

60Mo | / | 75um 45um 37um 25um |

/ | As additive for special part require anti-wear and anti-corrosion, like auto valve shaft guide pipe, seat etc. |

| HRCr12Mo | Cr:10 Mo:1.5 C:0.06 Mn:0.1 S:0.022 P:0.022 Si’╝Ü1.0 Fe:bal. |

12CrMo | / | 75micron 53micron 45micron |

/ | this alloy powder contain Cr and Mo content, can provide good anti-wear, anti-corrosion performance, it is usually to produce special part which need above performance. |

| HRMnS | Mn:62-65 S:33-36 O:0.5 Other: 1max |

MnS | / | 300mesh D95:10-12micron |

/ | As additive, function is lubricaiton. |

| HRFeC1# Carbonyl Iron powder |

Fe:98%min C:0.8%max N:0.6%max O:0.4%max |

CF1-1 | App.:2.2min Tap:4.0min |

D10:0.5-1.0um D50:2.0ummax D90:3.0-5.0um |

/ | / |

| HRFeC1# Carbonyl Iron powder |

Fe:98%min C:0.8%max N:0.6%max O:0.4%max |

CF1-2 | App.:2.5min Tap:3.9min |

D10:0.6-1.5um D50:2.0-3.0um D90:4.5-8.0um |

/ | / |

| HRFeC1# Carbonyl Iron powder |

Fe:98%min C:0.8%max N:0.6%max O:0.4%max |

CF1-3 | App.:2.5min Tap:3.8min |

D10:1.0-3.0um D50:3.0-5.0um D90:5.0-12.0um |

/ | / |

| HRFeC1# Carbonyl Iron powder |

Fe:98%min C:0.9%max N:0.7%max O:0.4%max |

CF1-4 | App.:2.2min Tap:3.5min |

D10:1.5-3.5um D50:5.0-6.0um D90:11.5-16.5um |

/ | / |

| HRFeC2# Carbonyl Iron powder |

Fe:99.5%min C:0.05%max N:0.01%max O:0.2%max |

CF2-2 | App.:2.5min Tap:3.8min |

D10:0.9-3.0um D50:3.0-5.0um D90:5.5-12.0um |

/ | / |

| HRFeC2# Carbonyl Iron powder |

Fe:99.5%min C:0.05%max N:0.01%max O:0.2%max |

CF2-3 | App.:2.5min Tap:3.6min |

D10:1.5-3.0um D50:5.0-8.0um D90:10-18um |

/ | / |

| Other Carbonyl Iron powder | we have more than 20grades, please contact our sales to get more details | |||||

Available Finishes

The finish option with the quickest turnaround.

Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants.

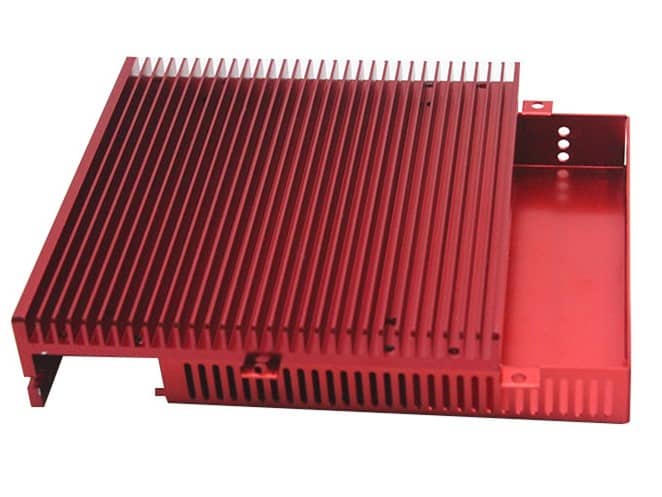

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in coating and is then cured under heat to allow it to flow and form a “skin”. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware and automobile and bicycle parts.

- Electroplating

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, weŌĆÖll look into a finishing process for you.

Metal Injection Molding (MIM) Applications

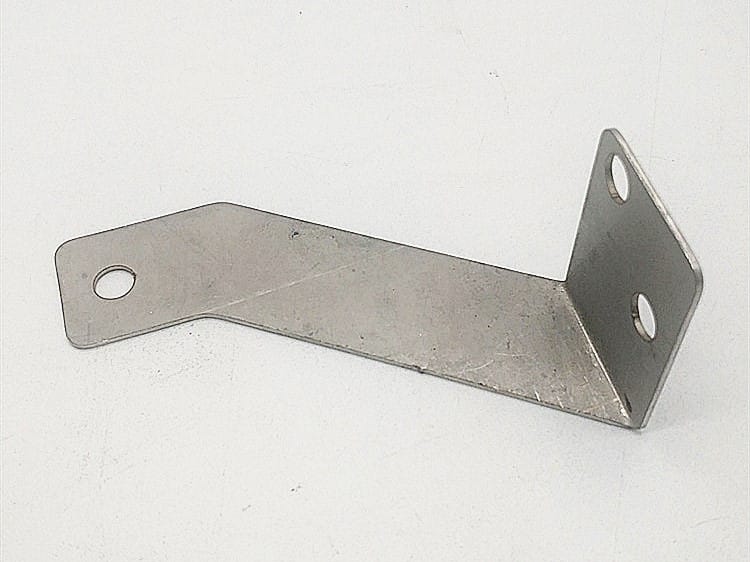

Whether you need a bracket, frame, or any other complex metal design, metal injection molding will do it. Make handles, clamps and other industrial tools with lower cost than CNC machining. Gears, locking parts and bearings are the most commonly produced with MIM technology.Commercial Steel Products

Industrial Steel Products

Spare steel parts

Industries with Metal Injection Molding (MIM)

Resources for Metal Injection Molding (MIM)