Urethane Casting Services

Low volumes with production-level quality, ideal for 1-100+ parts.

Overview: How urethane casting works?

The Basics Of Urethane Casting Services

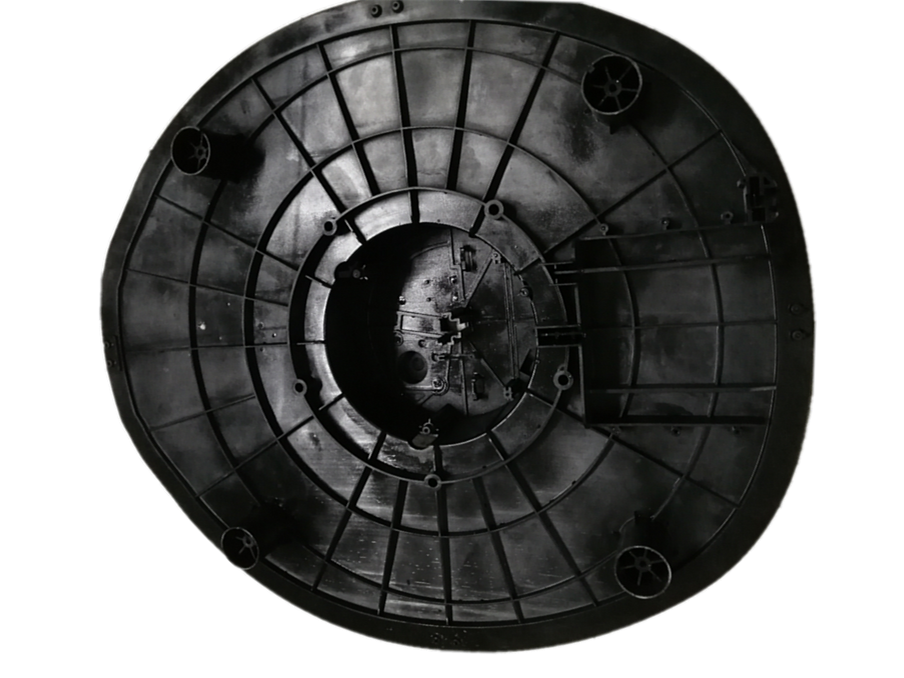

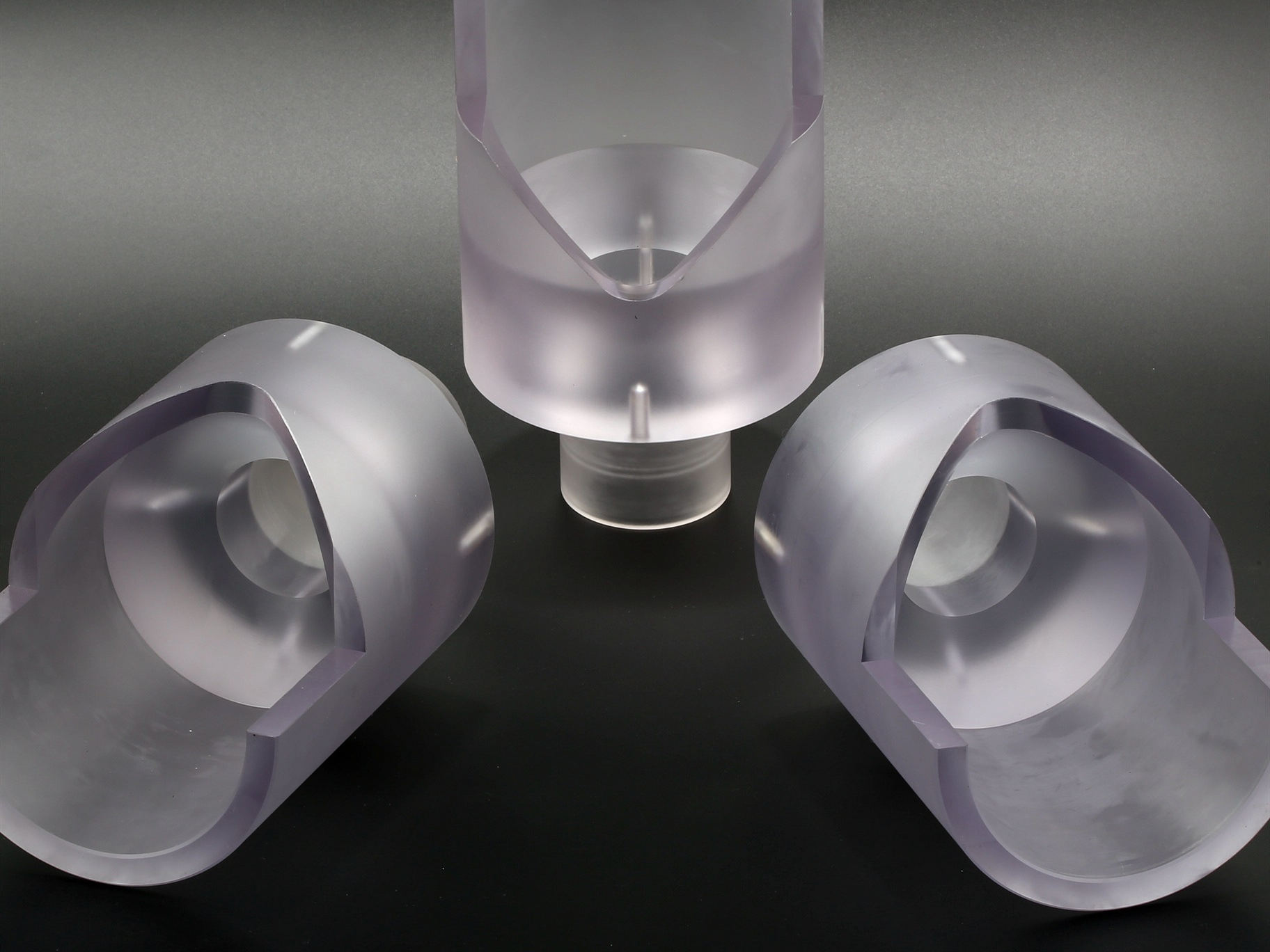

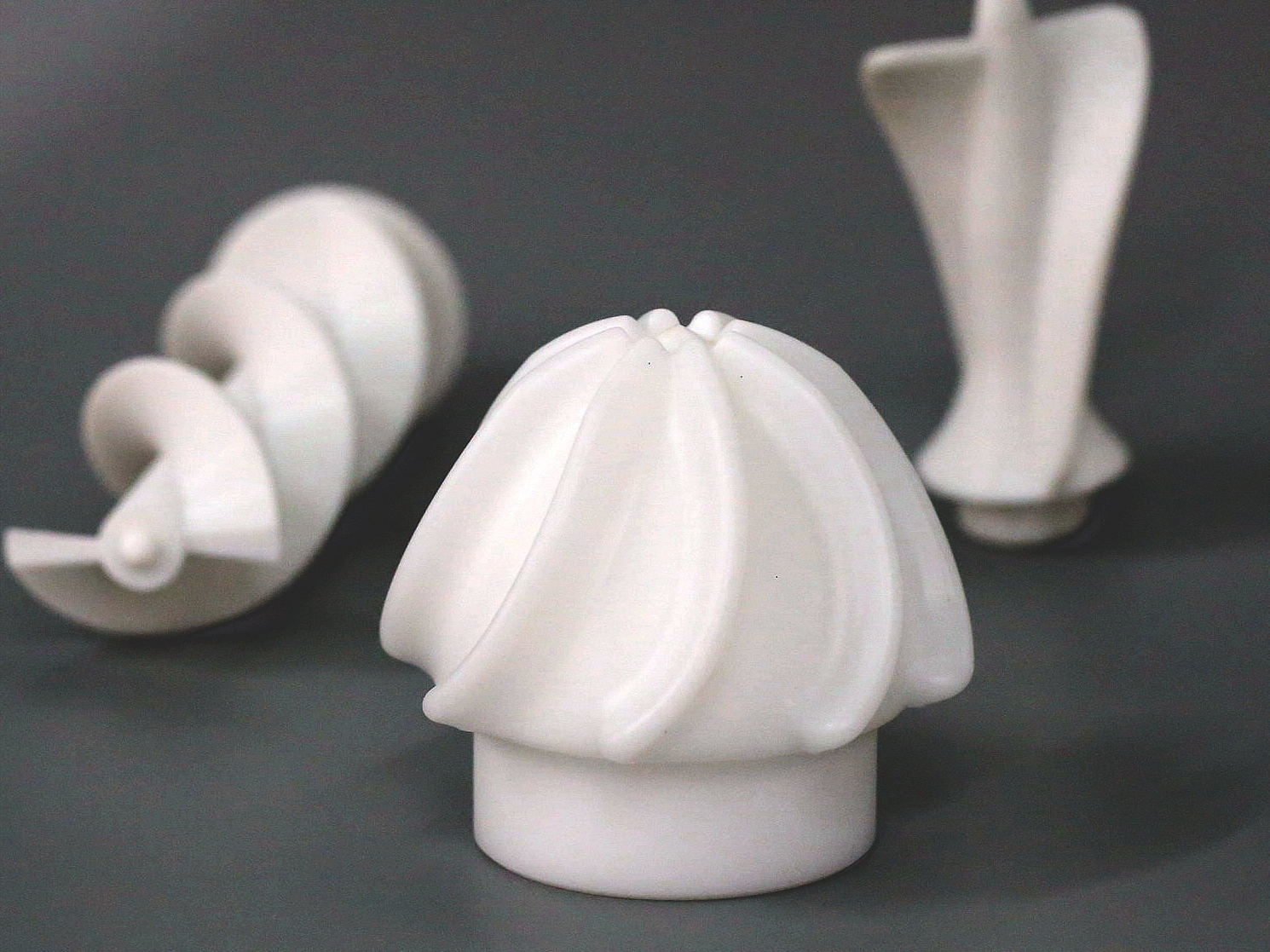

Urethane Casting (Also known as polyurethane vacuum casting, or silicon mold casting) is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

Urethane casting provides end-use, rigid or flexible, plastic parts with production-level quality. Built without expensive and time-consuming hard tooling, the urethane casting process uses a 3D-printed prototype and silicone mold to deliver high-quality, short-run parts in a fraction of the time and a fraction of the cost of injection molding.

Benefits Of Urethane Casting

- Low cost for molds

- Molds can be made in a few days

- Many types of polyurethane resins are available for casting, including overmolding

- Cast copies are highly accurate with excellent surface texture

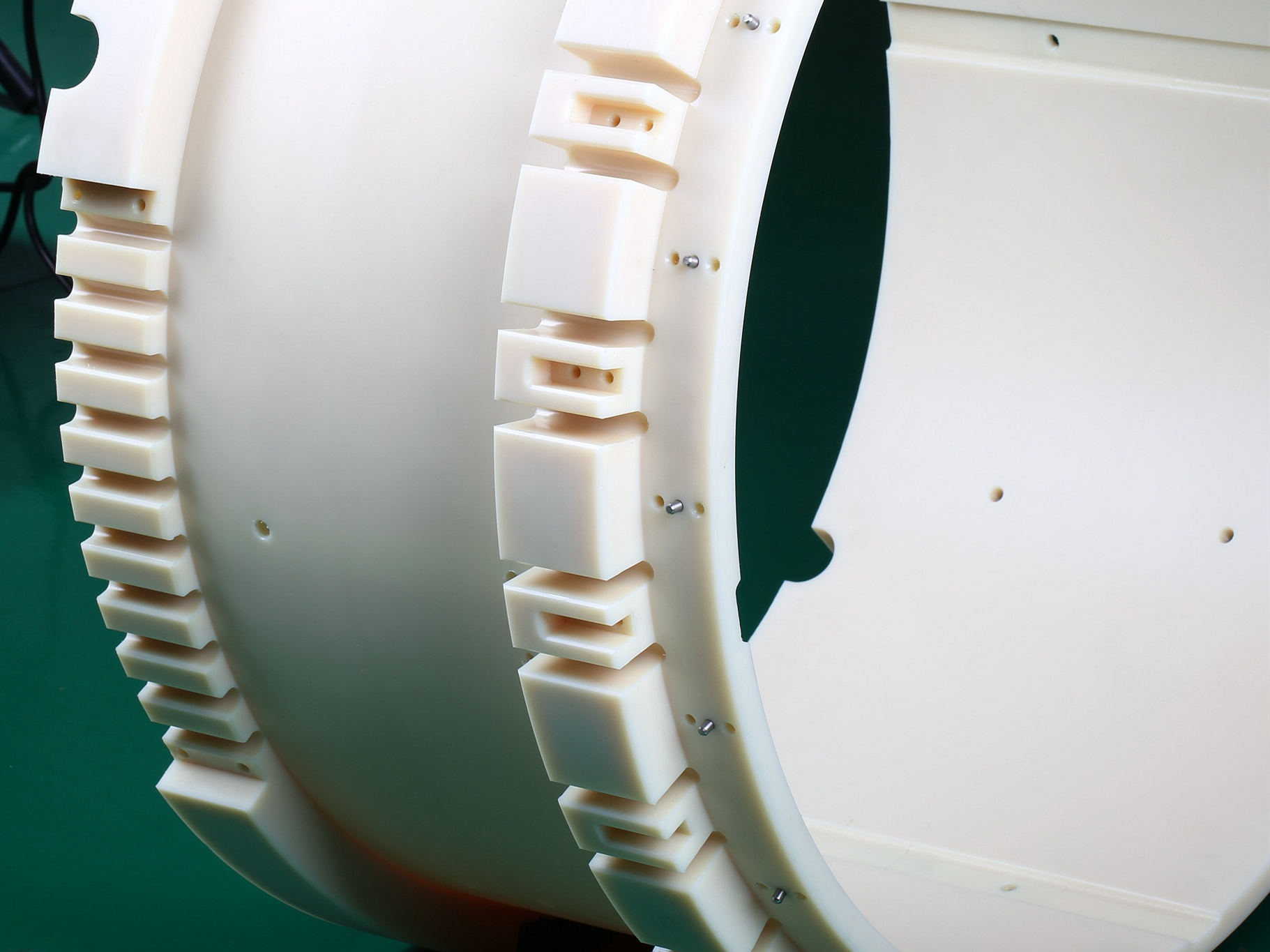

- Molds are durable for 10 or more copies

- Perfect for engineering models, samples, rapid prototypes, bridge to production

Benefits Of Urethane Casting With FacFox

Our main process for low volume plastic parts production is cast urethane parts due to the fact that above ten parts, it overtakes CNC machining in terms of interests (price and lead time). The main reason is that tremendous economies of scale are generated thanks to the tooling.

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. WeŌĆÖll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.

Features of Urethane Casting

Advantages

Drawbacks

Urethane Casting Processes

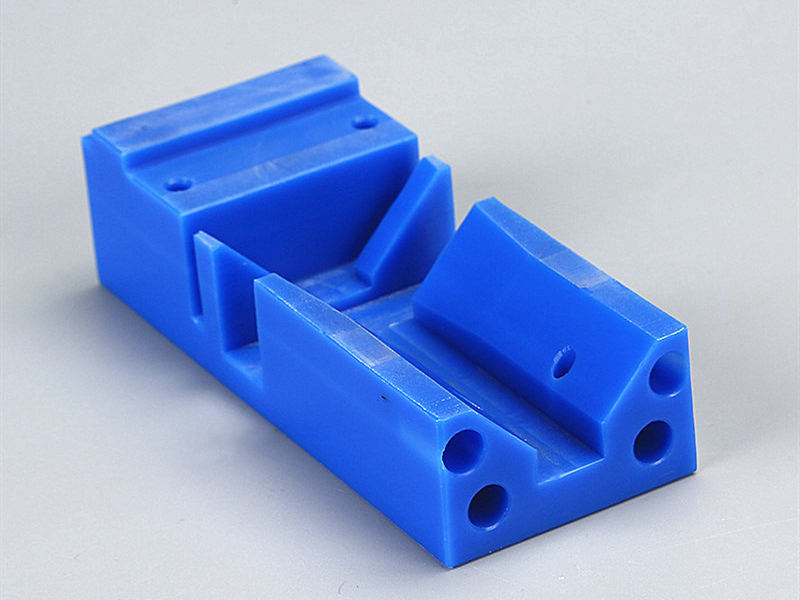

CNC milling is used to apply a machined surface finish on plastic or metal, or for creating complex 3D shapes. We use domestic and imported 3, 4 and 5-axis CNC machining centers with quick-change tooling, and advanced programming software. CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to low-volume production. EDM (electrical discharge machining) is a method for cutting holes, pockets and other shapes into hardened steel, as well as imparting a surface texture to the internal cavities of mold tools. ItŌĆÖs able to cut through hardened tool steels quickly and accurately.Master Pattern

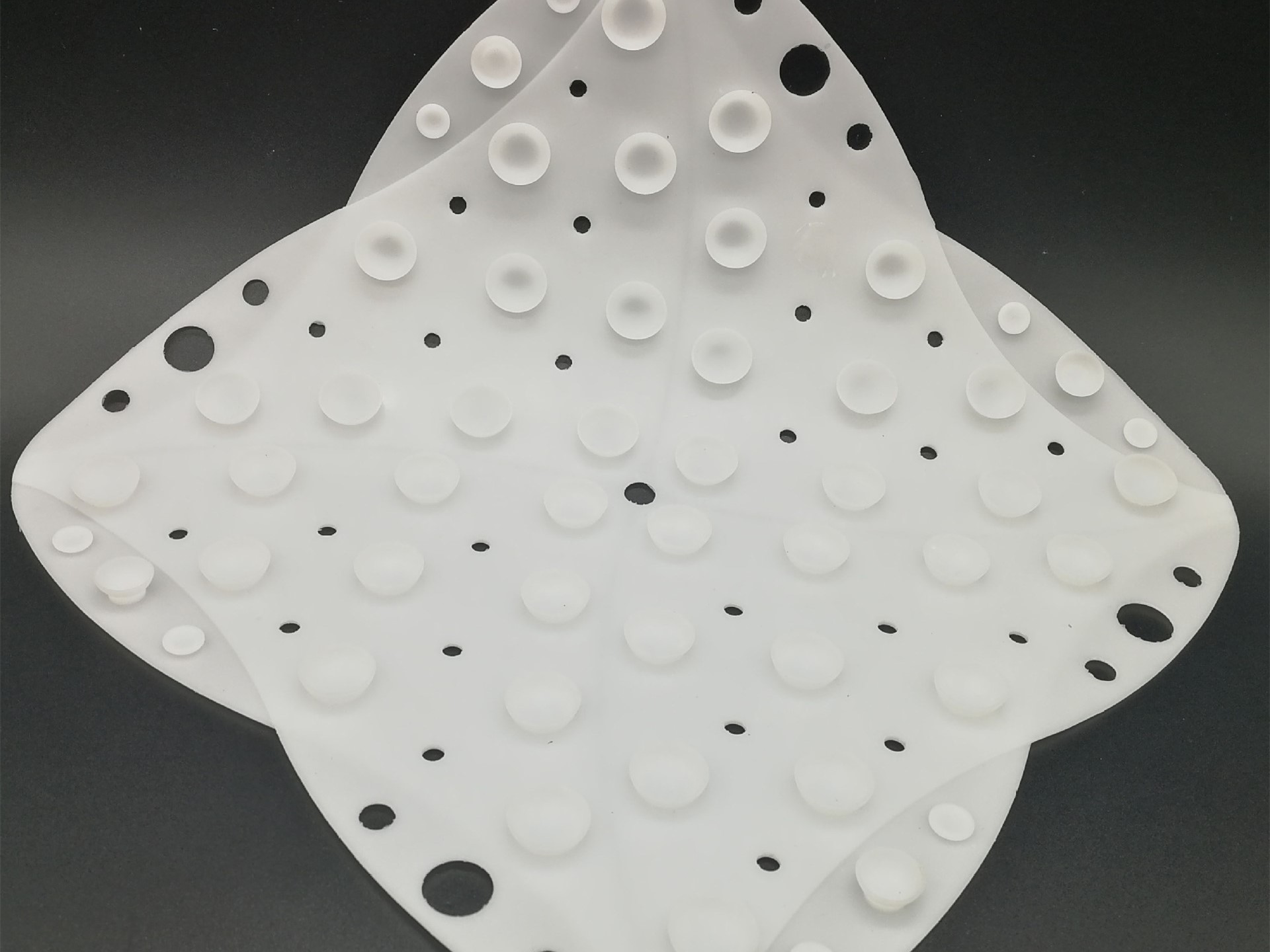

Making Mold

EDM / Wire EDM

Available Materials

Available Finishes

The finish option with the quickest turnaround.

Parts are left with visible print layer lines (generated by 3D printed master patterns) and potentially sharp edges and burrs, which can be removed upon request.

Polishing and Painting gives the urethane casted parts a smooth and close-to-product look, we will first grind off the marks and layer lines on the part, then coat them with primer and polish them for 2-4 times, at last, the surface will be painted with your selected colors.

- Spray-Plating

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, weŌĆÖll look into a finishing process for you.

Urethane Casting Applications

With urethane casting, the prototype can be made using resin material that simulates the property of the real plastic material that will eventually be applied before the mass production. Fast turnaround makes it a good choice for functional prototyping. Urethane casting can be applied to make high-quality small batched products from 1-100 units, ideal for small businesses that wishes to test the market’s reaction to thier newly developed products.Prototypes

Small Batched Products

Industries with Urethane Casting

Resources for Urethane Casting