CNC Turning Services

High quality CNC milling services, parts ready in days.

Overview: How CNC Turning works?

The Basics Of CNC Turning

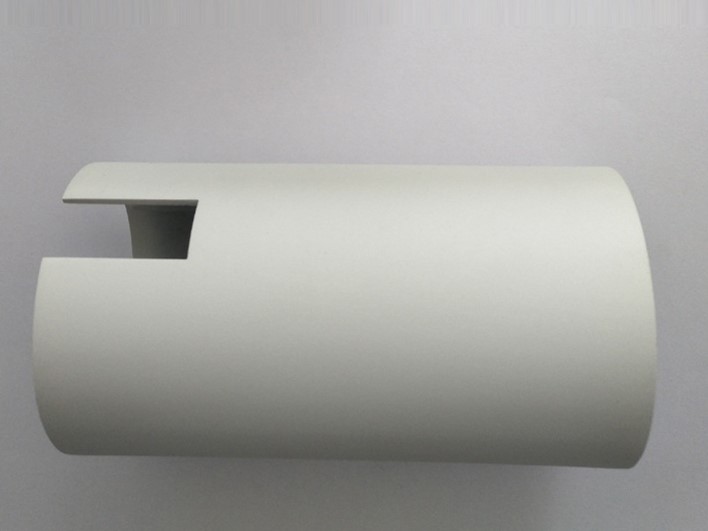

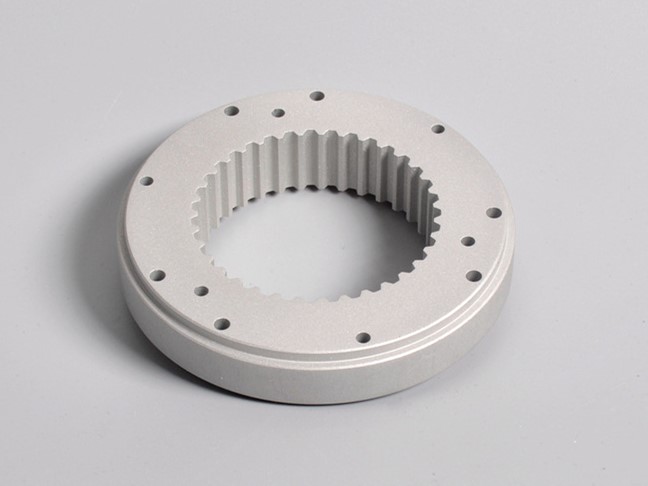

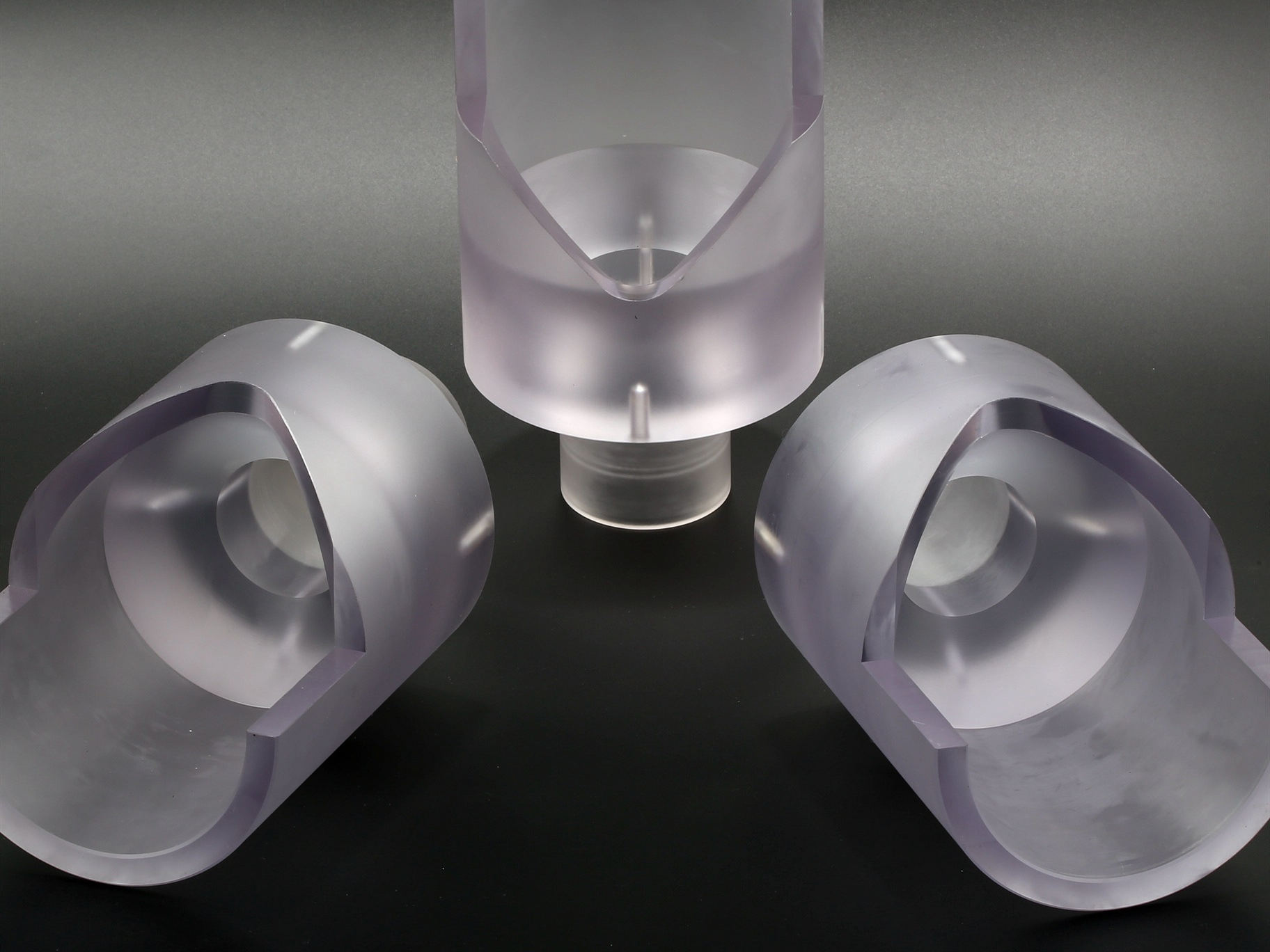

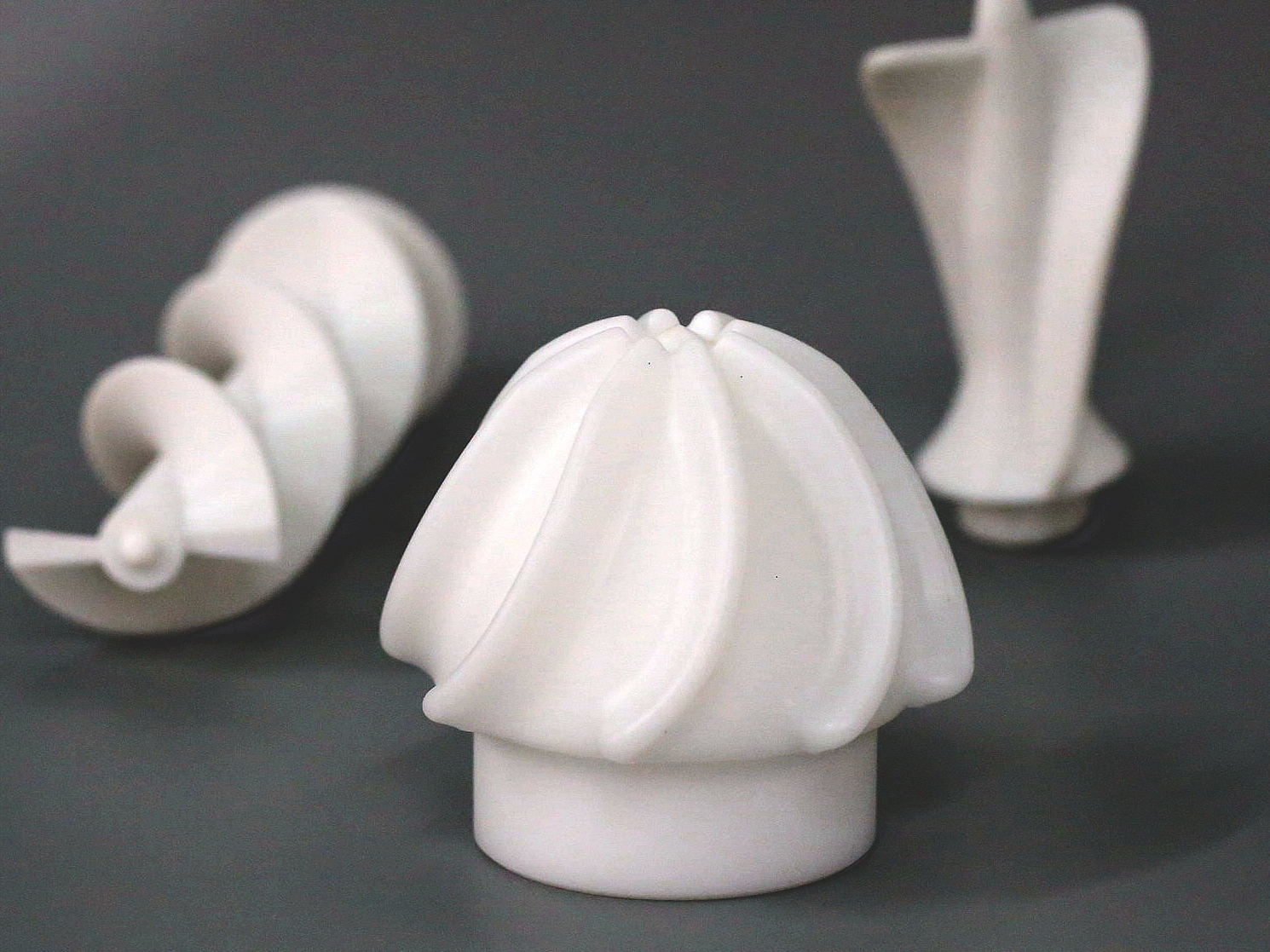

Turning is used for any rotationally symmetrical shape, to remove material quickly while leaving an excellent surface finish that sometimes requires no post-processing.

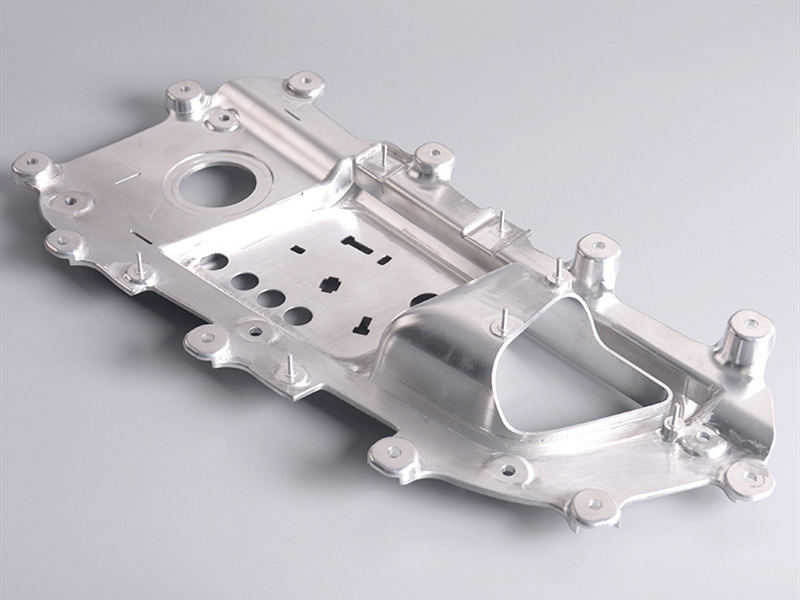

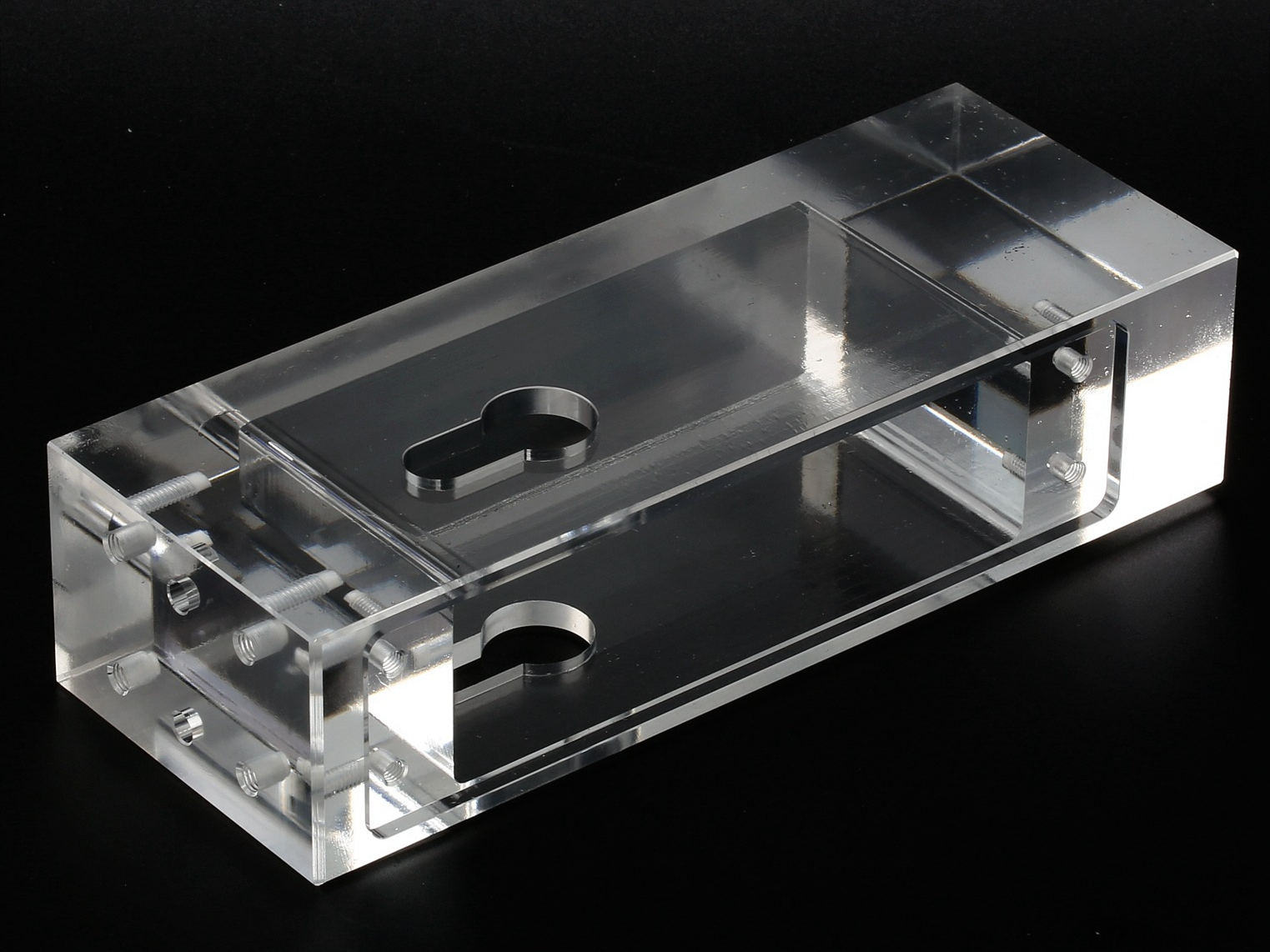

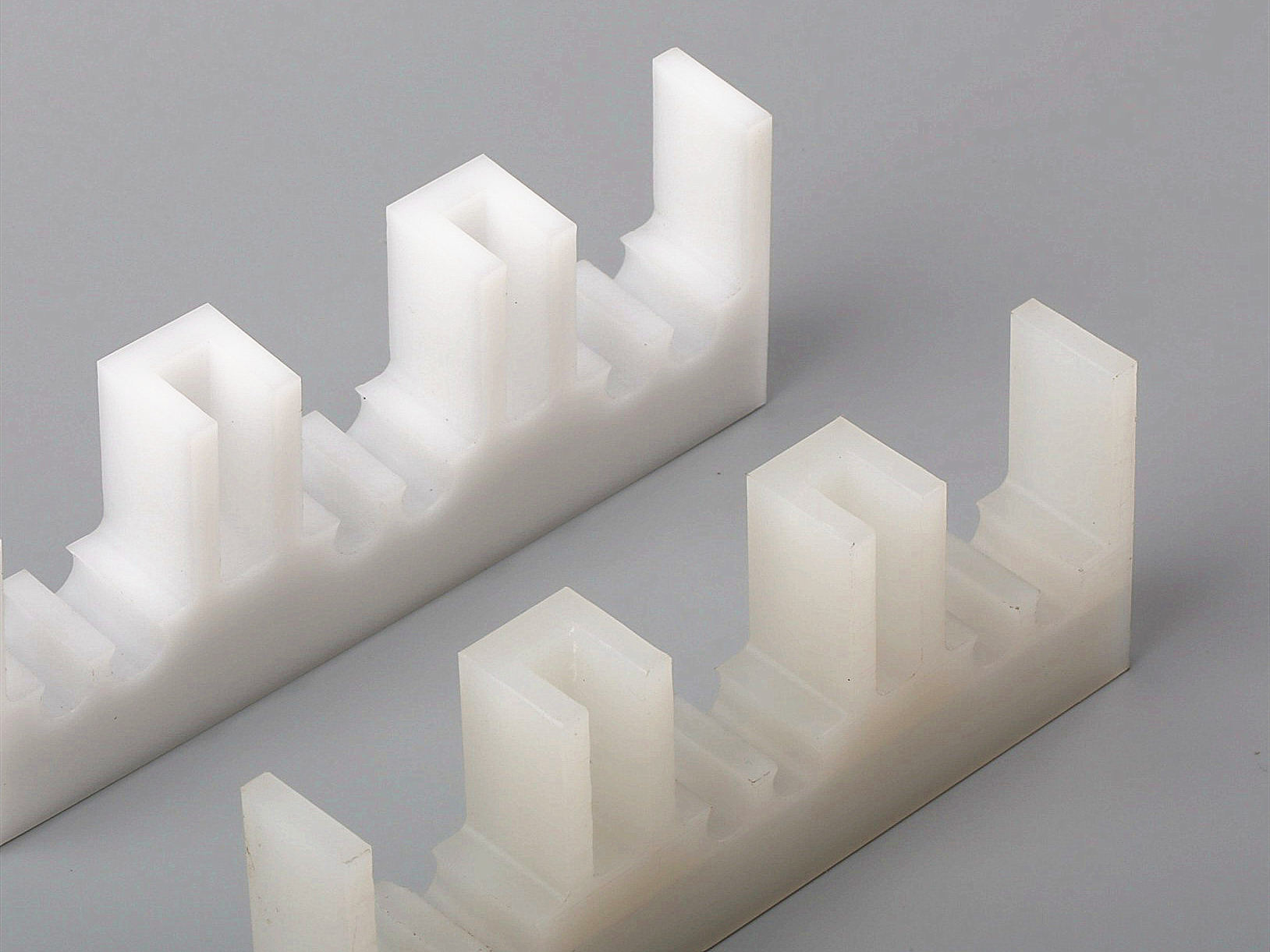

We use CNC turning not only to manufacture parts and prototypes but also to make mold tools, which can be used for our plastic injection molding or presure die casting services.

How CNC Turning Works

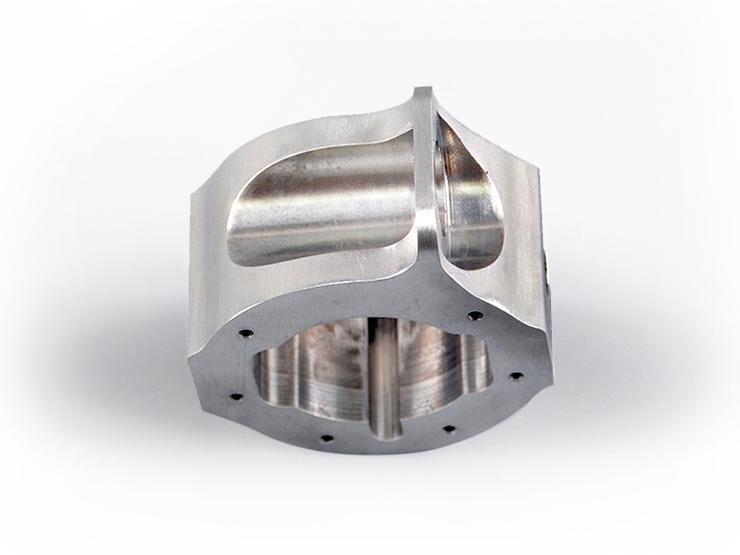

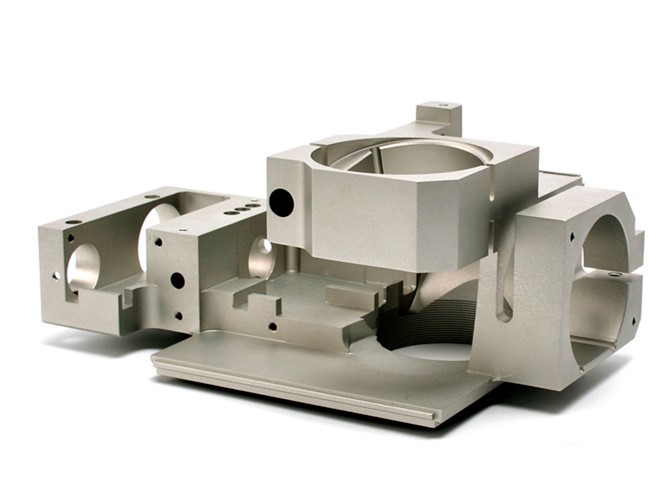

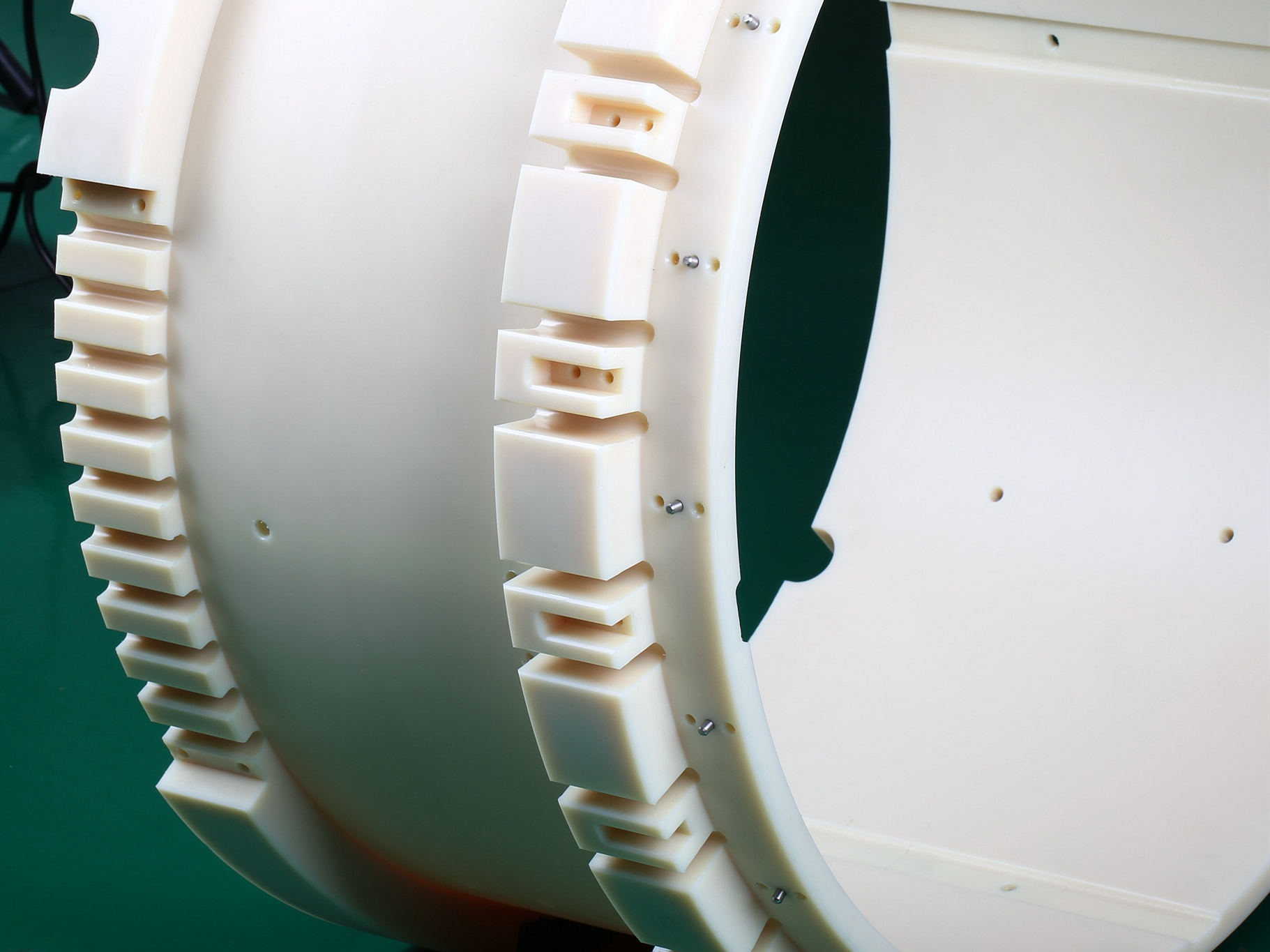

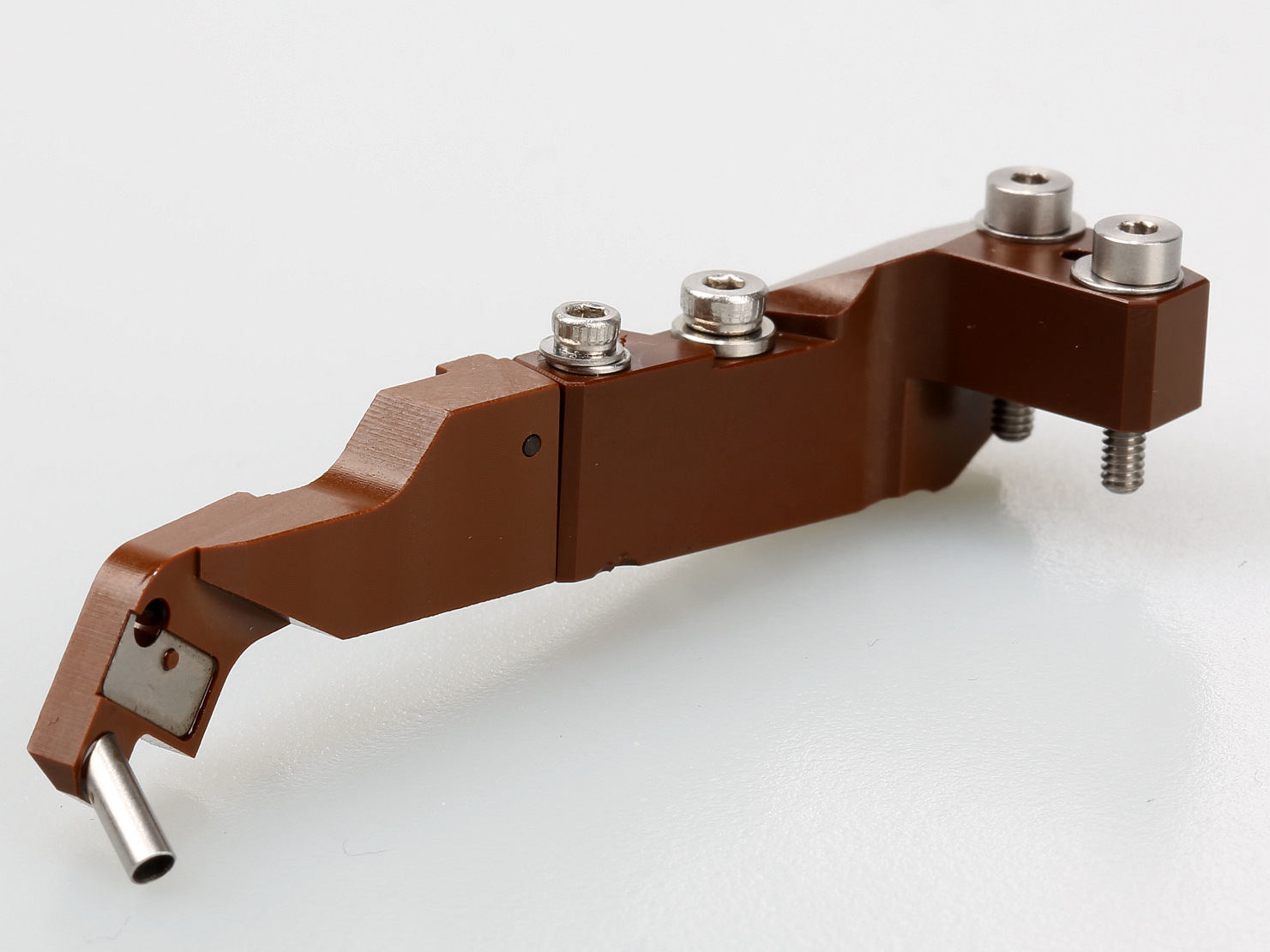

Turning involves holding the workpiece in a horizontally-mounted, adjustable spindle. As the workpiece rotates, various cutting tools are applied to the piece to create circular shapes and features like rings, grooves, slots, contours, radii, internal bores and threads. On our Haas turning mills, an extra axis of movement allows us to work perpendicular to the lathe spindle for making square faces or boring holes. This opens up many new machining possibilities.

When all turning operations are completed, the part is cut from the stock for further post-processing. The CNC lathe is then ready to repeat the operation with little-to-no set-up time in between.

Types Of CNC Turning

The most common are 2-axis CNC lathes and Swiss-type lathes. Swiss-type lathes are unique in that stock material is fed through a guide bushing, allowing the tool to cut nearer to the point of support, which makes them particularly useful for long, slender turned parts and micromachining. Some Swiss-type lathes also come equipped with a second tool head that operates as a CNC mill, allowing them to perform multiple machining operations without having to move the workpiece to a different machine. This makes Swiss-type lathes extremely cost-effective for complex turned parts.

Features of CNC

Advantages

Drawbacks

CNC Processes

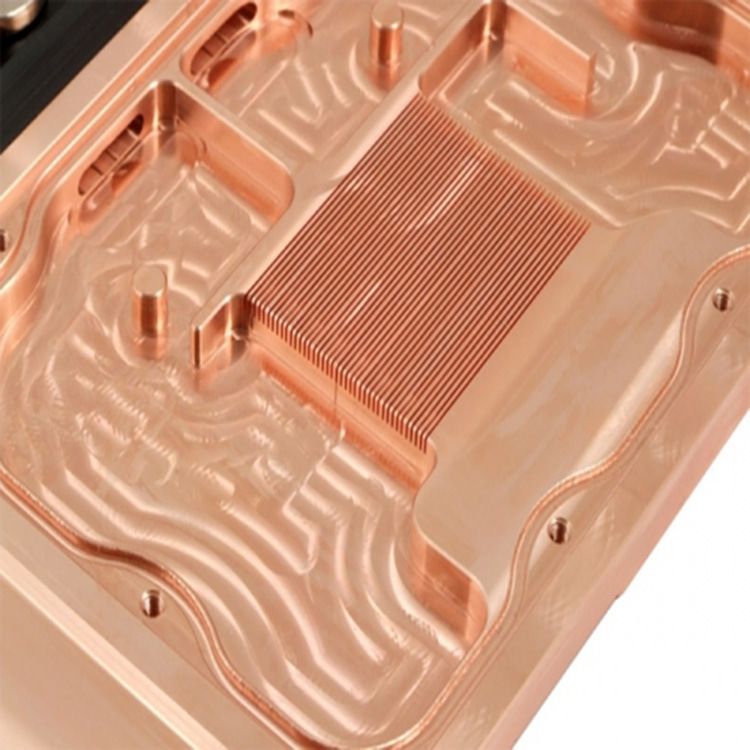

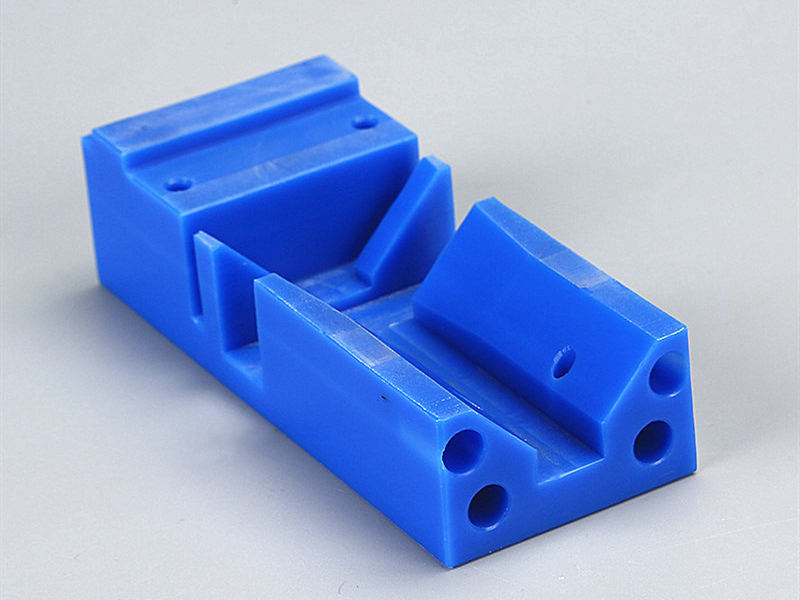

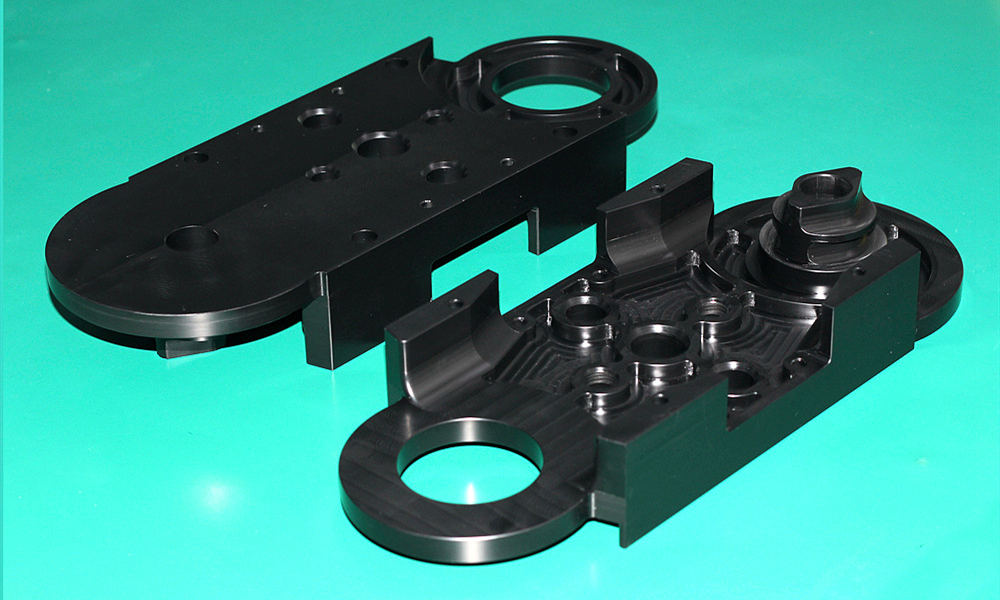

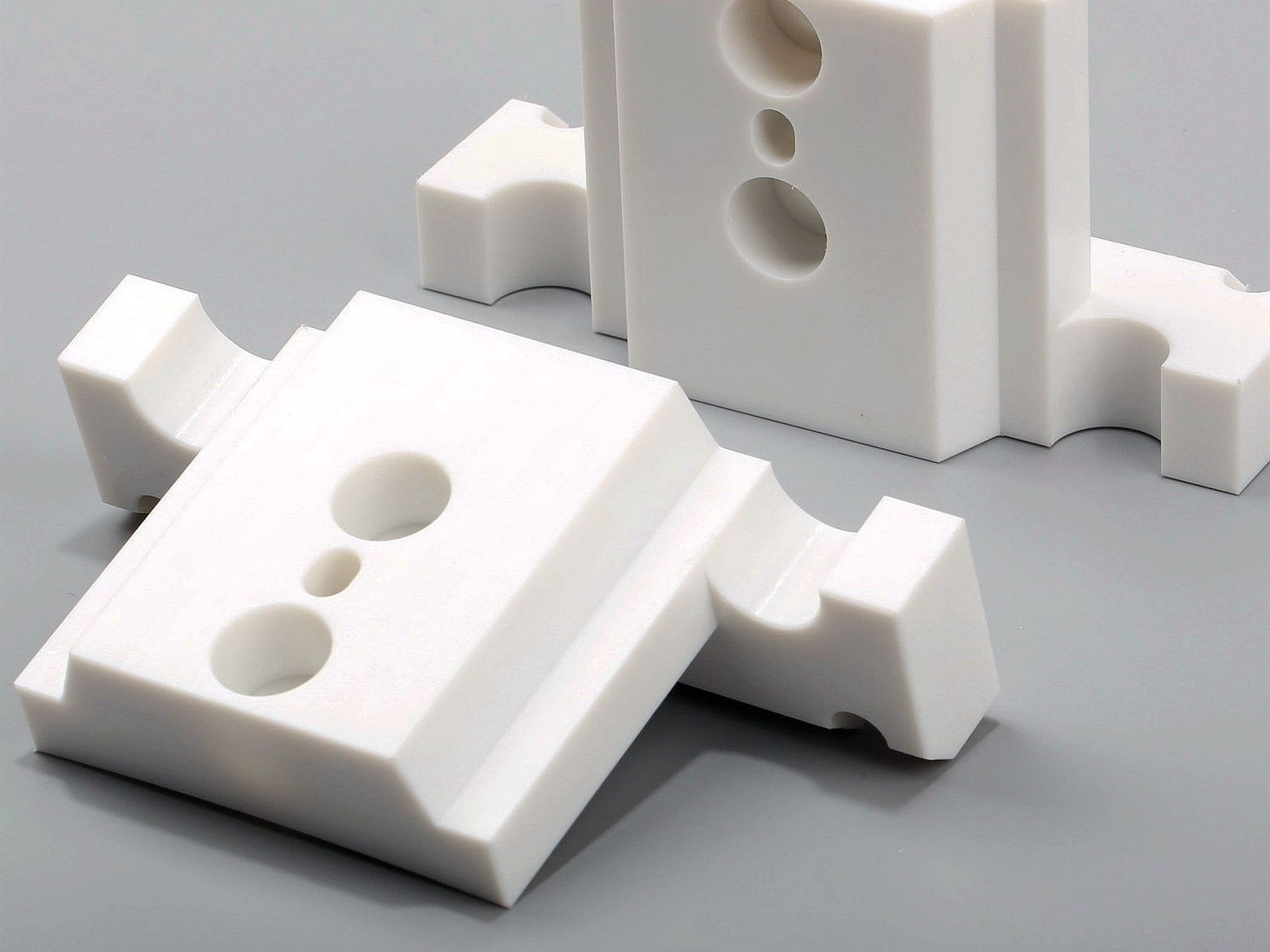

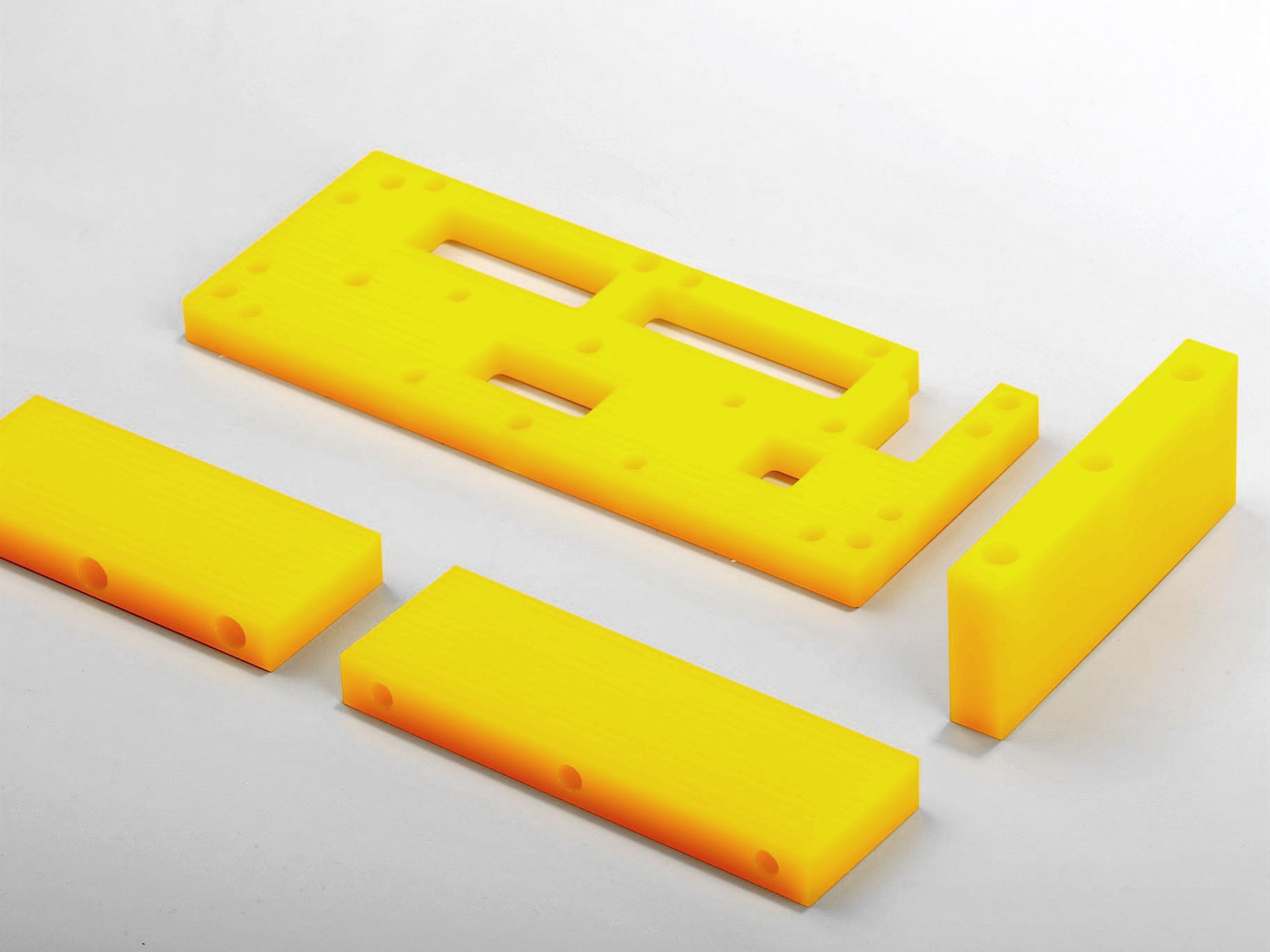

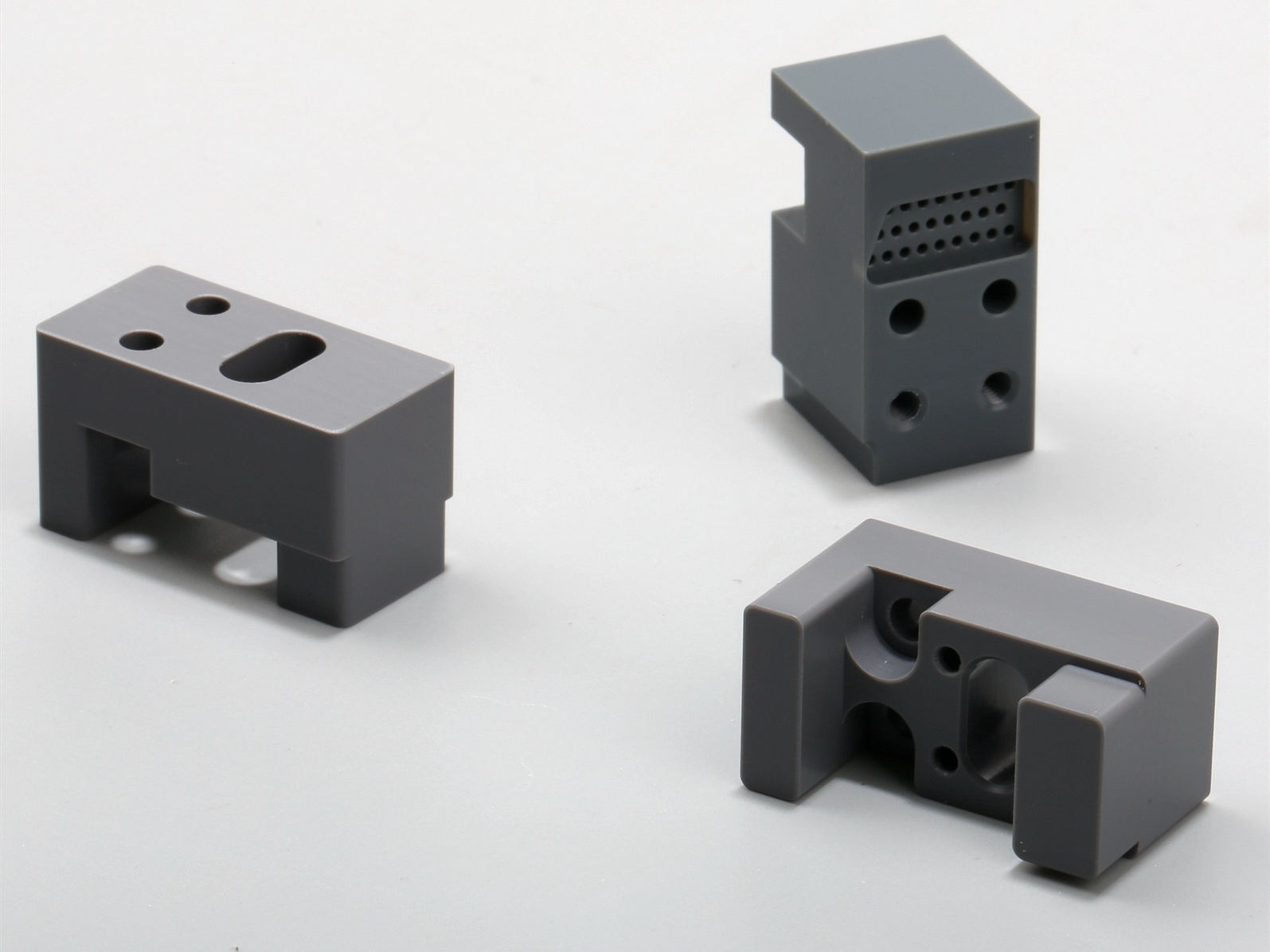

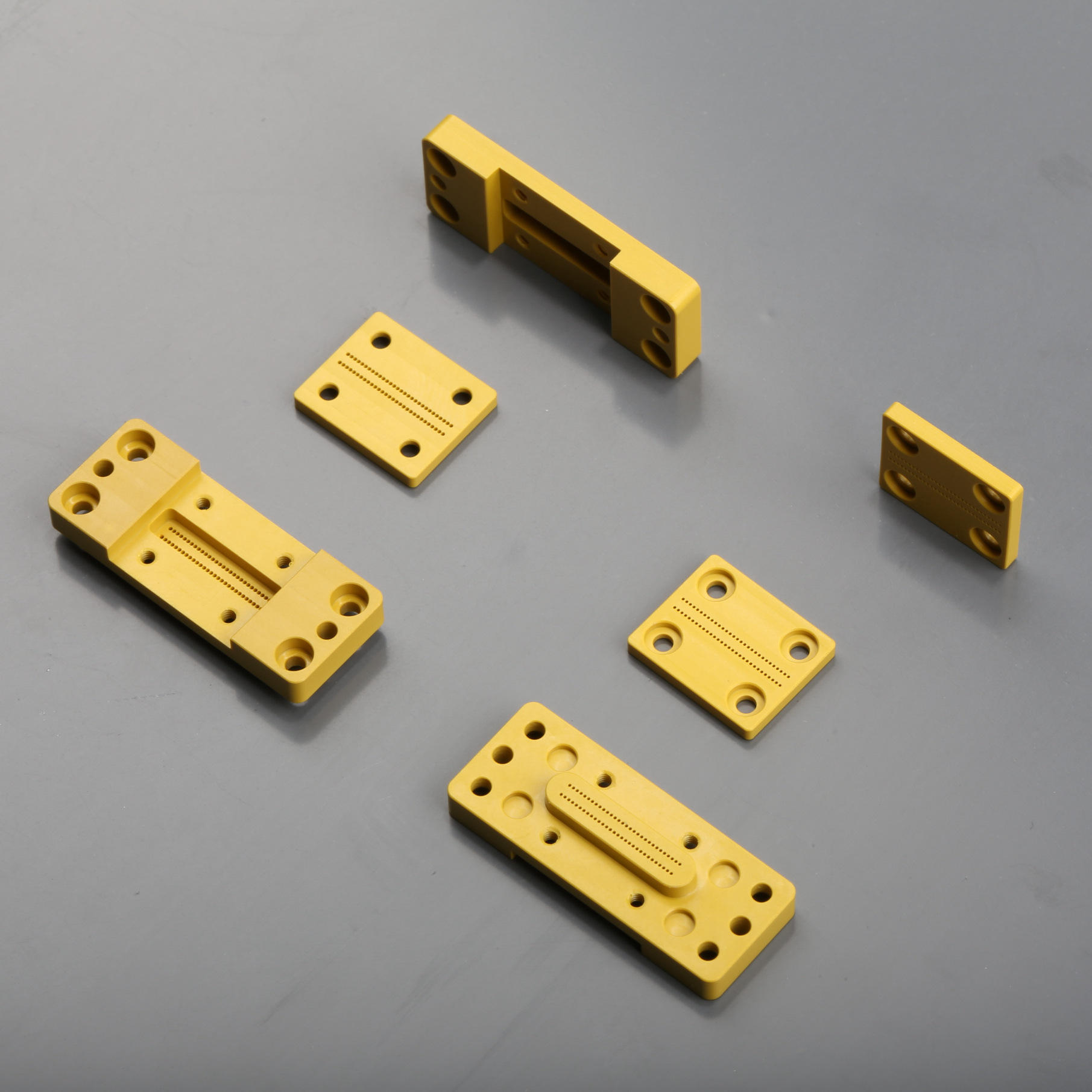

CNC milling is used to apply a machined surface finish on plastic or metal, or for creating complex 3D shapes. We use domestic and imported 2-axis CNC lathes and Swiss-type lathes with quick-change tooling, and advanced programming software. CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to low-volume production. EDM (electrical discharge machining) is a method for cutting holes, pockets and other shapes into hardened steel, as well as imparting a surface texture to the internal cavities of mold tools. ItŌĆÖs able to cut through hardened tool steels quickly and accurately.CNC Milling

CNC Turning

EDM / Wire EDM

Available Materials

Available Finishes

The finish option with the quickest turnaround.

Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in coating and is then cured under heat to allow it to flow and form a “skin”. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware and automobile and bicycle parts.

- Electroplating

- Spray-Plating

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, weŌĆÖll look into a finishing process for you.

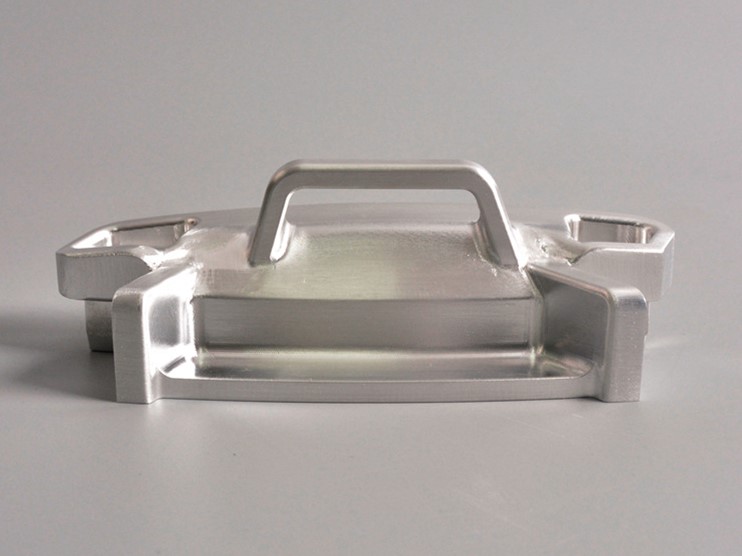

CNC Applications

With CNC turning, the prototype can be made using the exact material that will eventually be produced before the mass production. High tolerance makes it a good choice for functional prototyping. CNC can be applied to make high- quality tools from aluminum 7075-T6 for injection molding, while steel tooling made from P20, NAK80 and H13 is available for volumes up to 100,000 pieces. With CNC turning, the low volume end products can be made using the exact material that will eventually be produced before the mass production, some simple parts can even be mass produced.Prototypes

Mold Making

End Products

Industries with CNC

Resources for CNC